Nov . 02, 2024 10:34 Back to list

wholesale chlorination process titanium dioxide

The Wholesale Chlorination Process of Titanium Dioxide

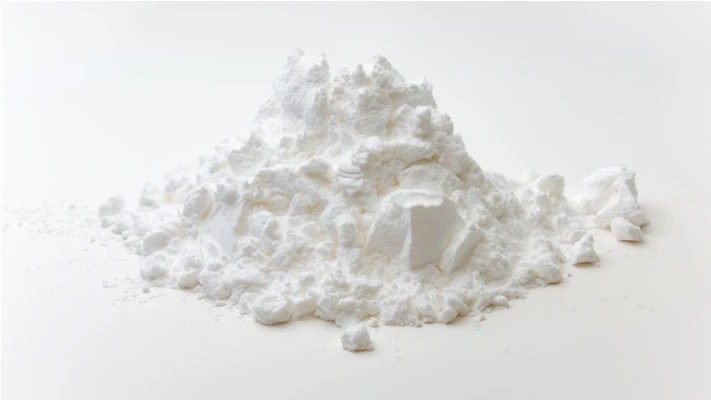

Titanium dioxide (TiO₂) is a widely used white pigment, known for its high opacity, brightness, and resistance to degradation. The wholesale chlorination process is one of the prominent methods for producing titanium dioxide, particularly when high purity and specific crystalline forms are desired. Understanding this process is crucial for manufacturers in the pigment industry, as it plays a vital role in determining the quality and application of the final product.

The wholesale chlorination process begins with the extraction of ilmenite or rutile, natural ores that contain titanium. These ores are first subjected to a suitable treatment to remove impurities. After purification, the ore is mixed with carbon and chlorine in a high-temperature reactor. The primary chemical reactions in this stage convert titanium-containing minerals into titanium tetrachloride (TiCl₄), which is a key intermediate in the production process.

The reaction can be summarized as follows

\[ \text{TiO}_2 + 2 \text{Cl}_2 + \text{C} \rightarrow \text{TiCl}_4 + \text{CO}_2 \]

wholesale chlorination process titanium dioxide

Once titanium tetrachloride is produced, it is necessary to separate it from unreacted materials and other byproducts. This is typically done through a distillation process. The purified TiCl₄ is then subjected to a hydrolysis reaction, where water is introduced to produce titanium dioxide

\[ \text{TiCl}_4 + 2 \text{H}_2\text{O} \rightarrow \text{TiO}_2 + 4 \text{HCl} \]

This step is critical for producing high-quality titanium dioxide, as the control of reaction conditions can influence the crystalline structure of the TiO₂ produced. The two principal forms of titanium dioxide resulting from this process are anatase and rutile. The preference for one form over the other depends on the desired properties of the pigment and its intended applications.

The final product undergoes thorough washing, drying, and milling to achieve the required particle size and distribution. These physical modifications enhance the performance characteristics of titanium dioxide in applications ranging from paints and coatings to plastics, cosmetics, and food products. In a wholesale context, ensuring consistent quality and adherence to regulatory standards is imperative for manufacturers, particularly when supplying large quantities to various industries.

In summary, the wholesale chlorination process is an integral method for the production of high-purity titanium dioxide. Through a series of chemical reactions and stringent processing steps, manufacturers can achieve a pigment that meets the diverse needs of a global market. As industries continue to demand higher-quality materials, the importance of mastering this process will remain paramount for producers of titanium dioxide.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025