Ott . 10, 2024 20:27 Back to list

ttk titanium dioxide factories

The Role of TT Titanium Dioxide Factories in Modern Industry

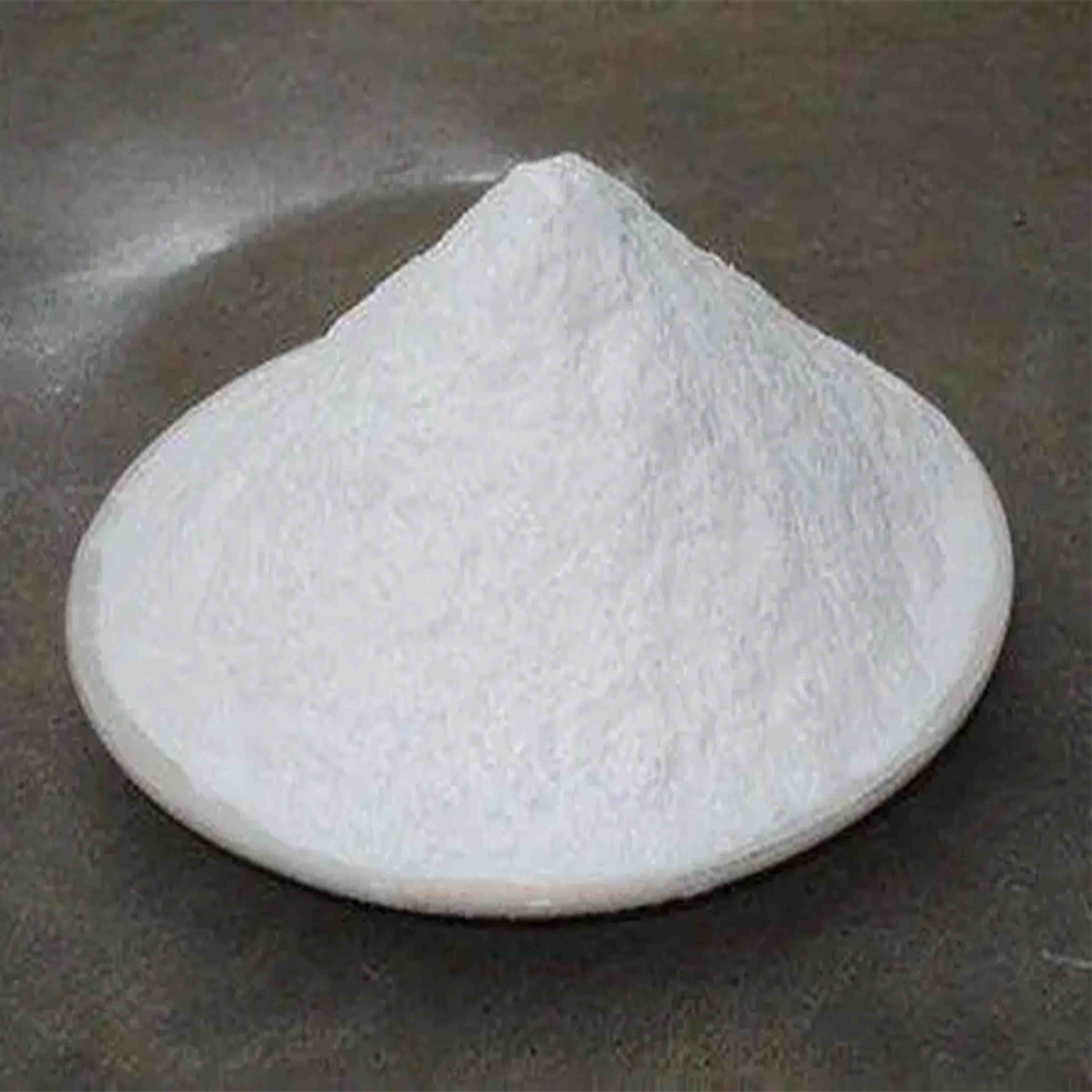

Titanium dioxide (TiO2) is one of the most versatile and widely used materials in the world. Found in a multitude of products, it serves as a pigment, a sunblock, and even as a food additive. The manufacturing of titanium dioxide, particularly through the TT (Titanium Technologies) process, plays a critical role in various industries, including construction, paint, plastics, and cosmetics. This article will delve into the significance of TT titanium dioxide factories, their manufacturing processes, environmental considerations, and the future of the industry.

Understanding Titanium Dioxide

Titanium dioxide is primarily valued for its brilliant whiteness and opacity. It is used as a pigment in paints, coatings, and plastics, due to its ability to enhance durability while providing a brighter and whiter appearance. Besides its pigmentation properties, TiO2 is widely utilized in applications such as cosmetics for its opacity in sunblock creams and as a photocatayst in treating air pollution.

The TT Manufacturing Process

TT titanium dioxide factories employ several production methods. The two most common are the sulfate process and the chloride process. The sulfate process involves sulfatizing titanium ore with sulfuric acid, while the chloride process utilizes titanium tetrachloride. Among these, the chloride process is generally preferred for manufacturing high-purity TiO2 with superior optical properties.

In TT factories, the chloride process begins with the extraction and purification of titanium ore. The titanium ore is then transformed into titanium tetrachloride through chlorination. Following that, the titanium tetrachloride undergoes oxidation in a reactor where it is converted back into titanium dioxide. This process is not only efficient but also produces less waste and is more environmentally friendly compared to traditional methods.

Environmental Considerations

While TT titanium dioxide factories contribute significantly to various industries, they also pose environmental challenges. The production process can generate waste materials and emissions, which need to be carefully managed to mitigate their impact on the environment. Many TT factories have implemented advanced pollution control technologies and sustainability practices to minimize their carbon footprint and make their operations more eco-friendly.

ttk titanium dioxide factories

The industry is also facing scrutiny regarding the health effects of titanium dioxide. In recent years, some studies have raised concerns about the safety of inhaling airborne titanium dioxide particles, particularly in occupational settings. As a response, TT titanium dioxide manufacturers are working to comply with regulatory standards and are investing in research to better understand and address potential health concerns.

Economic Impact

TT titanium dioxide factories play a vital role in the global economy. They create job opportunities and support local economies through the procurement of raw materials, employment of skilled workers, and the production of high-demand products. The global market for titanium dioxide is substantial, with demand being driven by growth in construction, automotive, and consumer goods industries.

Additionally, the factories promote innovation by encouraging research and development of new TiO2 applications. As technology advances and new products are developed, the scope and marketability of titanium dioxide continue to expand.

The Future of TT Titanium Dioxide Factories

Looking ahead, TT titanium dioxide factories are poised to benefit from emerging trends such as sustainability and increasing demand for eco-friendly products. As regulatory pressures and consumer preferences shift toward greener alternatives, TT manufacturers are expected to adapt their processes and product offerings accordingly.

Moreover, advancements in nanotechnology may open up new avenues for titanium dioxide applications, particularly in the fields of renewable energy and electronics. The potential for TiO2 to be utilized in photovoltaic cells, for instance, could revolutionize the solar energy industry, driving further demand for titanium dioxide.

In conclusion, TT titanium dioxide factories are integral to various industrial applications and continue to evolve in response to technological advancements and environmental challenges. The balance between maintaining production efficiency and embracing sustainability will determine the future landscape of the titanium dioxide industry. As the world moves towards greener practices, TT factories will be at the forefront of innovation, paving the way for a brighter and more sustainable future in the manufacturing sector.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025