Nov . 12, 2024 17:41 Back to list

determination of barium as tio2 supplier

Determination of Barium as TiO2 Supplier

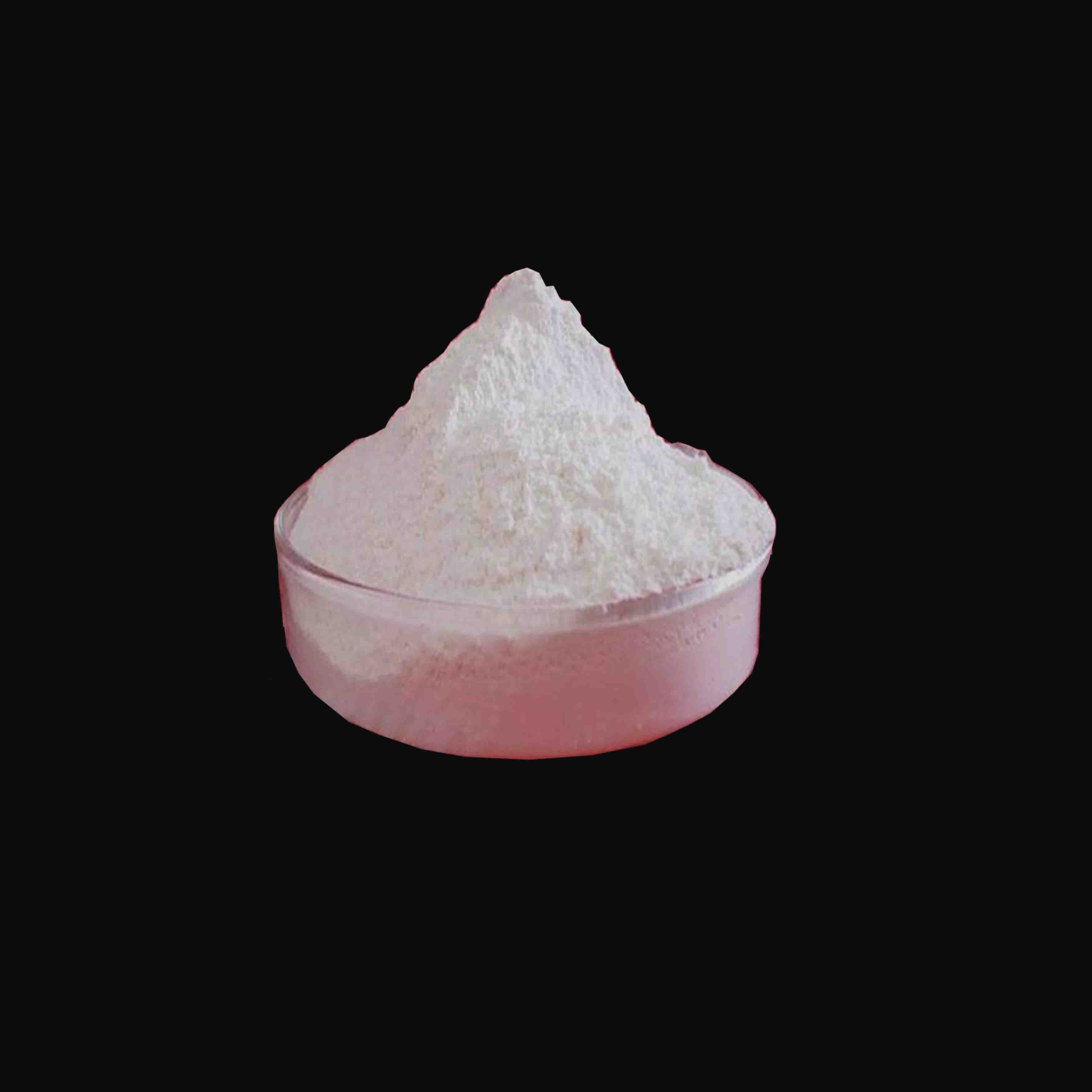

In recent years, the demand for titanium dioxide (TiO2) has surged due to its extensive applications in industries such as paints, coatings, plastics, and cosmetics. This heightened demand has spurred interest in identifying alternative materials and suppliers that can enhance the production and quality of TiO2. One such material that has garnered attention is barium, which is often considered for its potential role in TiO2 production.

Determination of Barium as TiO2 Supplier

To determine the efficacy of barium as a TiO2 supplier, it is crucial to investigate the synthesis methods that can incorporate barium into the TiO2 matrix effectively. Various methods, including sol-gel processes, hydrothermal synthesis, and co-precipitation, have been explored for this purpose. Each method has its advantages and drawbacks regarding the homogeneity of the final product, control over particle size, and operational efficiency.

determination of barium as tio2 supplier

Additionally, the role of barium in enhancing the photocatalytic properties of TiO2 has been a focal point of research. Studies suggest that doping TiO2 with barium can improve its photocatalytic activity under sunlight, which is particularly beneficial for applications in environmental remediation and energy production. By increasing the electron mobility and reducing the recombination rates of photogenerated electron-hole pairs, barium-doped TiO2 demonstrates improved performance in catalytic reactions.

Another essential aspect to consider is the environmental impact and economic feasibility of using barium in TiO2 production. Barium is abundant in nature, and its extraction and processing are generally cost-effective compared to other rare materials. Therefore, evaluating the life-cycle cost, including raw material sourcing, production processes, and end-of-life disposal, is vital in determining the viability of barium as a TiO2 supplier.

Moreover, regulatory standards surrounding the use of heavy metals must be carefully examined. As with any material, the safety and environmental implications of incorporating barium into TiO2 must align with global regulations to ensure sustainable production practices.

In conclusion, the determination of barium as a TiO2 supplier presents a promising avenue for research and industrial application. By exploring innovative synthesis methods and understanding the intrinsic properties of barium-doped TiO2, manufacturers can develop enhanced TiO2 products that meet the growing market demands while adhering to environmental standards. Future studies will undoubtedly shed more light on the full potential of barium in the realm of titanium dioxide manufacturing.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025