Sep . 01, 2025 11:11 Back to list

Titanium Dioxide for Paper Industry: Opacity and Printability

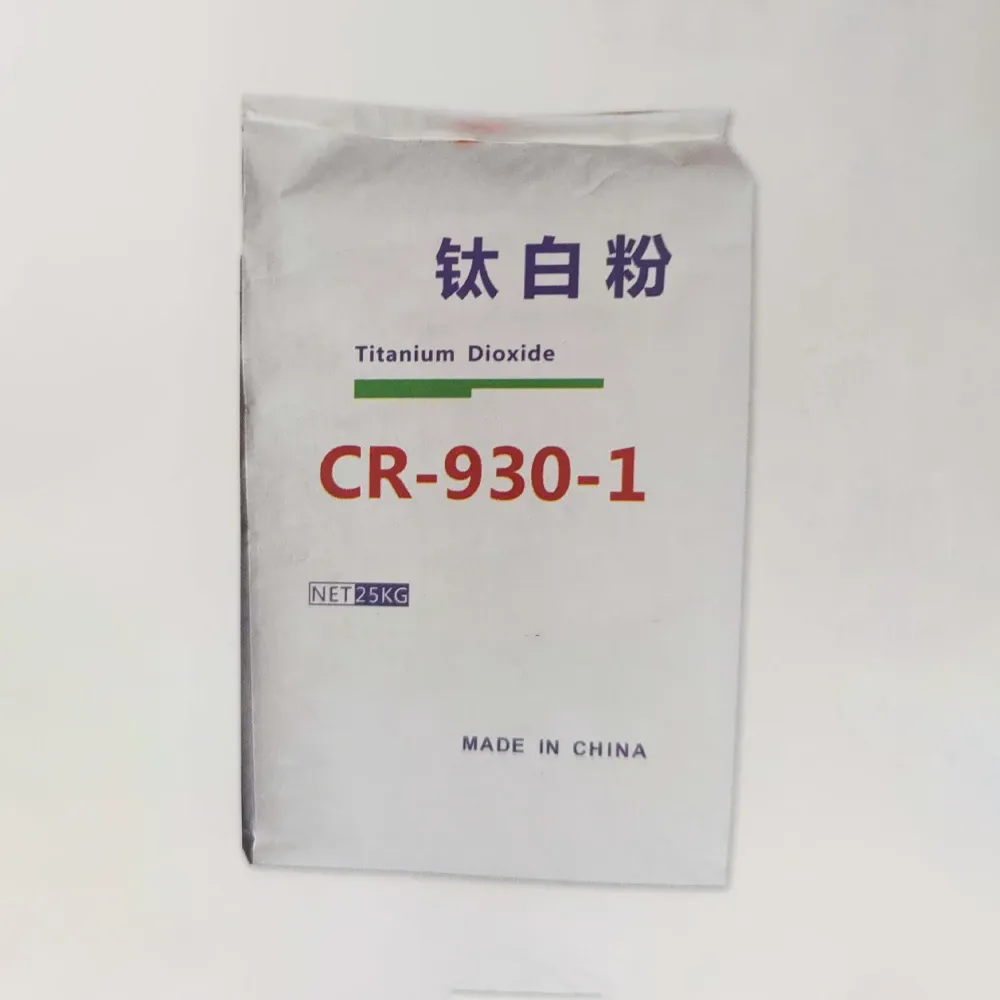

The paper industry relies heavily on titanium dioxide (TiO₂) powder to achieve superior opacity, brightness, and printability in high-quality paper products. As a key titanium dioxide pigment, TiO₂ enhances the visual and functional properties of paper, making it indispensable for premium printing, packaging, and specialty paper applications. Titanium dioxide manufacturers produce different grades of TiO₂ powder, tailored to meet the specific needs of papermakers, balancing cost, performance, and environmental considerations.

Why Titanium Dioxide Powder is Essential for Paper Opacity

Opacity is a critical quality parameter in paper production, especially for lightweight papers that must prevent show-through (where text or images on one side are visible on the other). Titanium dioxide powder, due to its high refractive index (2.7 for rutile TiO₂), scatters light more effectively than other fillers like calcium carbonate or kaolin. This property allows papermakers to use thinner sheets while maintaining excellent opacity, reducing material costs without sacrificing quality.

Paper manufacturers source TiO₂ powder in two primary forms:

Rutile titanium dioxide – Preferred for its superior light-scattering ability and durability.

Anatase titanium dioxide – Sometimes used where a slightly lower refractive index is acceptable, often at a reduced cost.

Titanium dioxide manufacturers optimize particle size distribution to maximize opacity while ensuring smooth dispersion in paper coatings. The fine, uniform particles of TiO₂ powder integrate seamlessly into paper pulp or coating formulations, providing consistent brightness and coverage.

Enhancing Printability with Titanium Dioxide Pigment

Printability—the ability of paper to hold ink sharply and vividly—is significantly influenced by surface smoothness, porosity, and brightness. Titanium dioxide pigment plays a dual role in improving print quality:

Surface Smoothness: When used in coatings, TiO₂ powder helps create an ultra-smooth surface, allowing for precise ink application and sharper image reproduction.

Ink Absorption Control: The right balance of titanium dioxide pigment in paper coatings ensures optimal ink holdout, preventing excessive absorption that can lead to dull prints or bleeding.

Premium printing papers, such as those used for magazines, catalogs, and high-end packaging, often contain higher TiO₂ concentrations to achieve the best print results. Titanium dioxide for sale in the paper industry is typically supplied in slurry or dry powder form, depending on the paper mill’s coating process.

Titanium Dioxide in Paper Coatings vs. Fillers

The application of titanium dioxide paint coating principles extends to the paper industry, where TiO₂ is used in two primary ways:

1. As a Coating Pigment

In coated papers, TiO₂ powder is mixed with binders (such as latex or starch) and applied to the paper surface. This method maximizes opacity and gloss, making it ideal for high-end printing papers. The coating process is similar to how titanium dioxide paint coating works—forming a thin, uniform layer that enhances surface properties.

2. As a Filler in Paper Pulp

For uncoated papers, titanium dioxide powder can be added directly to the pulp before sheet formation. While this method is less efficient than coating (since some TiO₂ is lost in the papermaking process), it still improves brightness and opacity at a lower cost.

Titanium dioxide manufacturers often recommend specific grades of TiO₂ powder based on whether it will be used in coatings or fillers, ensuring optimal performance in each application.

Titanium Dioxide’s Sustainability and Environmental Considerations

As the paper industry moves toward more sustainable practices, titanium dioxide manufacturers are developing eco-friendly TiO₂ solutions:

Reduced TiO₂ Usage: Advances in dispersion technology allow papermakers to achieve the same opacity with less titanium dioxide pigment, lowering costs and environmental impact.

Recycled Paper Compatibility: New TiO₂ formulations are being tested for better performance in recycled paper, where contaminants can affect brightness and print quality.

Low-Carbon Production: Some titanium dioxide manufacturers are shifting to renewable energy sources to produce TiO₂ powder, reducing the carbon footprint of paper production.

Despite these advancements, the titanium dioxide price remains a significant factor for paper mills, as TiO₂ is one of the most expensive components in paper manufacturing. However, its unparalleled performance in opacity and printability ensures continued demand.

Titanium Dioxide’s Irreplaceable Role in Paper Quality

Titanium dioxide powder remains a cornerstone of the paper industry, delivering unmatched opacity, brightness, and printability. Whether used as a coating or filler, TiO₂ powder ensures that premium papers meet the high standards required for publishing, packaging, and commercial printing.

Titanium dioxide manufacturers continue to refine their products, offering titanium dioxide for sale in forms that balance performance, cost, and sustainability. As paper technology evolves, TiO₂ will remain essential—driving innovation in both traditional and next-generation paper products.

For papermakers, investing in high-quality titanium dioxide pigment is not just about aesthetics—it’s about ensuring that their products perform flawlessly in an increasingly competitive market.

-

Application of Titanium Dioxide 2195 in Water Purification

NewsNov.14,2025

-

What are the global market trends of Titanox titanium dioxide in recent years

NewsNov.14,2025

-

Effect of particle size distribution on the optical properties of R996 TiO2

NewsNov.14,2025

-

Latest Technological Innovations in Rutile Titanium Dioxide Manufacturing

NewsNov.14,2025

-

Compatibility of Titanium Dioxide Concrete Pigment with Different Concrete Admixtures

NewsNov.14,2025

-

Environmental Impact of Titanium Dioxide Pigment Manufacturing and Mitigation Measures

NewsNov.14,2025