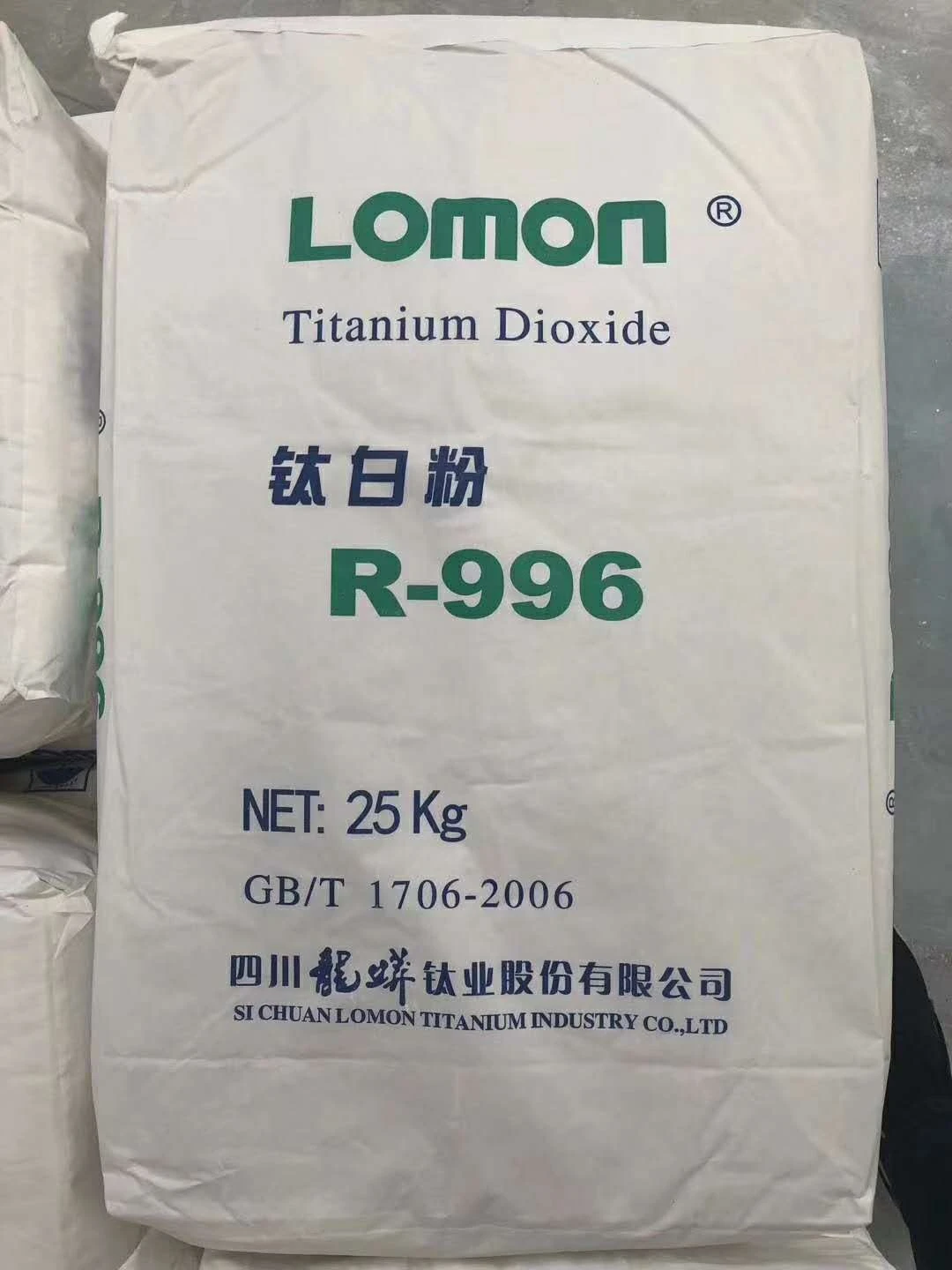

Industrial Chemial Tio2 for paint R-996 Titanium Dioxide Powder

अभी संपर्क करें

पीडीएफ में डाउनलोड करें

उत्पाद का प्रदर्शन

अखंडता प्रबंधन, पर्याप्त सूची, सही बिक्री के बाद सेवा, उच्च गुणवत्ता वाले उत्पाद, उचित मूल्य और विचारशील सेवा।

विनिर्देश

अखंडता प्रबंधन, पर्याप्त सूची, सही बिक्री के बाद सेवा, उच्च गुणवत्ता वाले उत्पाद, उचित मूल्य और विचारशील सेवा।

मुख्य विशेषताएं

उद्योग-विशिष्ट विशेषताएँ

|

CAS संख्या।

|

13463-67-7 |

|

पवित्रता

|

99% |

अन्य विशेषताएँ

|

वर्गीकरण

|

रंजातु डाइऑक्साइड |

| उत्पत्ति का स्थान | China |

| अन्य नामों | tio2 |

| म्यूचुअल फंड | टीआईओ2 |

| ईआईएनईसीएस नं. | 236-675-5 |

| ग्रेड मानक | औद्योगिक श्रेणी |

| उपस्थिति | white power |

| आवेदन | Coating,ink,paint,rubber,paper |

| प्रोडक्ट का नाम | रंजातु डाइऑक्साइड |

| Feature | Good whiteness,High hiding power,Good Weather resistance |

| Type | Rutile/anatase |

| पैकेट | 25 किग्रा/बैग |

| Sample | Availiable |

Packaging and delivery

| पैकेजिंग विवरण | 25kg/bag or as request |

| पत्तन | Tianjin port |

| Selling Units: | Single item |

| Single package size: | 15X15X15 cm |

| Single gross weight: | 1.200 kg |

समय सीमा

| मात्रा (किलोग्राम) | 1 - 25 | 26-1000 | 1001 -25000 | >25000 |

| लीड समय (दिन) | 5 | 7 | 15 | बातचीत करने के लिए |

LOMON Model R-996 Grade For coatings, rubber, plastics, papermaking, ink, chemical fiber, cosmetics, pigment, ceramic, enamel, nano, general purpose, other specifications and uses 25kg/bag Performance similar to DuPont R-902.

High cost performance color red CAS Rutile titanium dioxide, white powder, insoluble in water, non-physiological toxicity, stable chemical properties, surface after silicon, aluminum, zirconium coating and organic treatment has excellent pigment performance, whiteness, brightness, gloss; hiding power, tinting power and fluidity are strong Rutile titanium dioxide, white powder, insoluble in water, non-physiological toxicity, stable chemical properties, surface after silicon, aluminum, zirconium coating and organic treatment has excellent pigment performance, whiteness, brightness, gloss; hiding power, tinting power and fluidity are strong, with excellent weather resistance and anti-powdering performance,

Mainly used for powder coatings, water-based and solvent-based external coatings, high-grade masterbatch, plastics, rubber, ink, high-grade paper and wax paper and leather decorative fabrics.

The production process of titanium dioxide mainly includes sulfuric acid method and chlorination method:

Sulfuric acid method: Titanium iron powder is acid-hydrolyzed with concentrated sulfuric acid to produce titanium sulfate, which is hydrolyzed to form metatitanic acid, and then calcined and crushed to obtain the product. It can produce anatase and rutile titanium dioxide. The advantages are that it can use low-priced and easily available raw materials, mature technology, simple equipment, and easy to solve anti-corrosion materials. The disadvantages are long process, intermittent operation, wet operation, and more waste and by-products, which are highly polluting to the environment.

Chlorination method: titanium tetrachloride is generated by reacting titanium-containing raw materials with chlorine gas, which is then purified by distillation and then oxidized in gas phase, and then separated by gas and solid to obtain TiO2, which needs to be heated or steamed to remove the adsorbed chlorine. This process is simple and the product quality is better, but the investment is large, the equipment structure is complex, the material requirements are high, and the research and development are difficult.

Sulfuric acid method: Titanium iron powder is acid-hydrolyzed with concentrated sulfuric acid to produce titanium sulfate, which is hydrolyzed to form metatitanic acid, and then calcined and crushed to obtain the product. It can produce anatase and rutile titanium dioxide. The advantages are that it can use low-priced and easily available raw materials, mature technology, simple equipment, and easy to solve anti-corrosion materials. The disadvantages are long process, intermittent operation, wet operation, and more waste and by-products, which are highly polluting to the environment.

Chlorination method: titanium tetrachloride is generated by reacting titanium-containing raw materials with chlorine gas, which is then purified by distillation and then oxidized in gas phase, and then separated by gas and solid to obtain TiO2, which needs to be heated or steamed to remove the adsorbed chlorine. This process is simple and the product quality is better, but the investment is large, the equipment structure is complex, the material requirements are high, and the research and development are difficult.

कंपनी प्रोफाइल

अखंडता प्रबंधन, पर्याप्त सूची, सही बिक्री के बाद सेवा, उच्च गुणवत्ता वाले उत्पाद, उचित मूल्य और विचारशील सेवा।

पैकेजिंग वितरण

अखंडता प्रबंधन, पर्याप्त सूची, सही बिक्री के बाद सेवा, उच्च गुणवत्ता वाले उत्पाद, उचित मूल्य और विचारशील सेवा।

कंपनी शैली

अखंडता प्रबंधन, पर्याप्त सूची, सही बिक्री के बाद सेवा, उच्च गुणवत्ता वाले उत्पाद, उचित मूल्य और विचारशील सेवा।

अपना संदेश यहां लिखें और हमें भेजें