Май . 20, 2025 11:41 Вярнуцца да спісу

Why Titanium Dioxide Is the Most Important White Pigment?

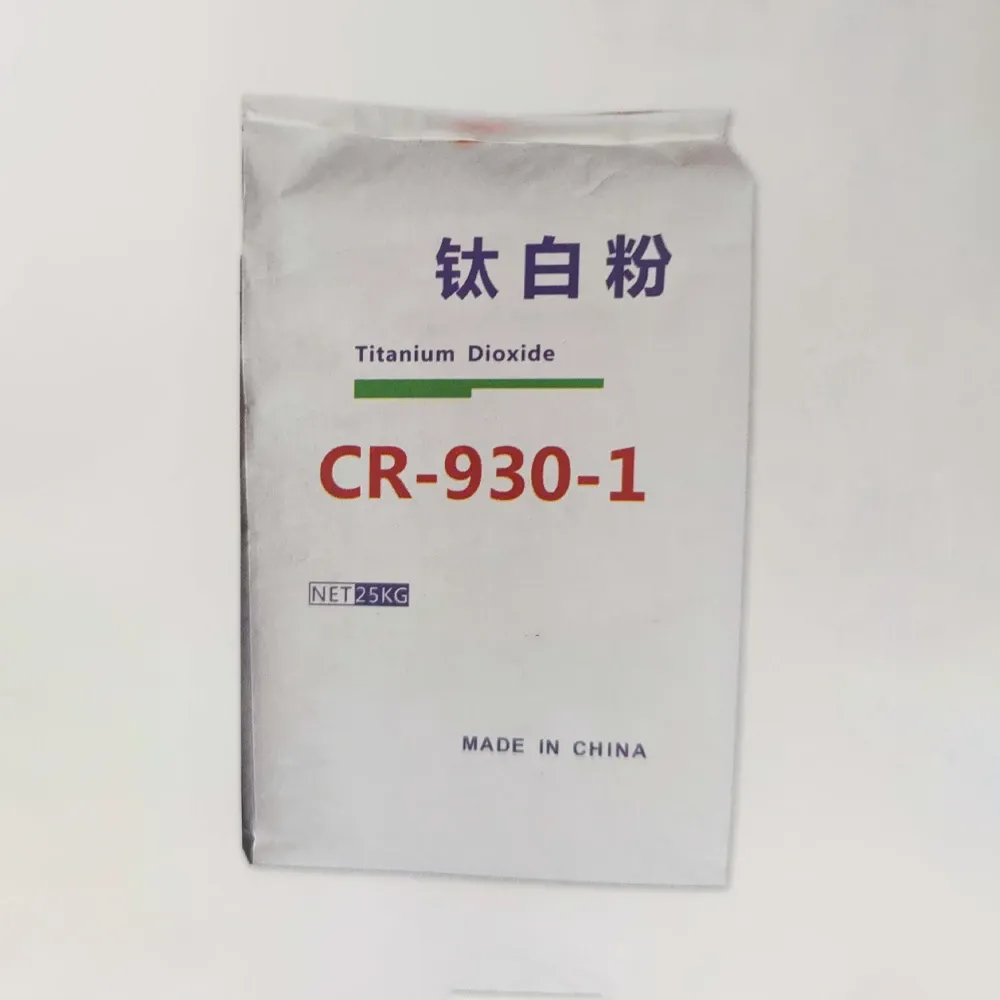

White pigments have been used for centuries, but none compare to the efficiency, brightness, and versatility of titanium dioxide. Known for its exceptional whiteness and opacity, titanium dioxide (TiO₂) has become the gold standard in industries ranging from paints and coatings to plastics, cosmetics, and even food. This article explores why titanium dioxide pigment is the most important white pigment in the world today.

The Unique Properties of Titanium Dioxide Powder

At the core of its popularity is the chemical structure and optical performance of titanium dioxide powder. TiO₂ is a white, odorless, and non-toxic powder with a high refractive index — even higher than diamond. This means that it reflects light extremely effectively, providing exceptional brightness and opacity when used in formulations.

The two most common crystalline forms used in industry are rutile and anatase, with rutile being more stable and offering better UV resistance. These characteristics make titanium dioxide powder an ideal ingredient in products where bright white color and long-term durability are essential.

Titanium Dioxide Pigment: A Champion in Light Scattering

The ability of titanium dioxide pigment to scatter visible light is unmatched. This light scattering effect is what gives it such incredible hiding power — the ability to mask the color of the surface underneath. This is particularly important in the paint and coatings industries, where complete coverage with fewer layers means lower cost and improved appearance.

In comparison to older white pigments such as zinc oxide, lithopone, or lead white (which is now banned due to toxicity), titanium dioxide offers superior safety, brightness, and longevity. Its high tinting strength allows manufacturers to use less pigment to achieve the same opacity, improving the efficiency of production and application.

Titanium Dioxide Paint: Bright, Durable, and UV-Resistant

When you pick up a can of bright white wall paint or glossy enamel, chances are the base pigment is titanium dioxide. Titanium dioxide paint is preferred across the globe because it produces a brilliant, clean white color and can be easily tinted into a wide spectrum of shades. Its durability, chemical stability, and UV resistance make it especially suitable for exterior paints, which must withstand harsh environmental conditions over time.

The UV-blocking ability of titanium dioxide also protects substrates from degradation, meaning not only does the paint look good longer, but the materials underneath are preserved better. This property is why it’s also a key ingredient in sunscreen formulations, although that uses a different grade of TiO₂ than in industrial paints.

Titanium Dioxide Coating: Protecting Surfaces Across Industries

Beyond just paints, titanium dioxide coating solutions are used in a variety of industrial and architectural applications. For instance, in powder coatings, automotive topcoats, marine finishes, and appliance coatings, TiO₂ delivers color, brightness, and protective qualities. In infrastructure, such as bridges and public buildings, titanium dioxide coatings help structures resist corrosion, chalking, and fading.

Some advanced titanium dioxide coatings even harness photocatalytic properties — when exposed to UV light, they can break down organic pollutants, creating self-cleaning and air-purifying surfaces. These coatings are increasingly used in urban environments to improve air quality and reduce maintenance needs.

Environmental and Safety Considerations Of Дыяксід тытана

One of the factors contributing to the dominance of titanium dioxide as a white pigment is its safety profile. When properly handled in industrial settings, titanium dioxide powder is considered non-toxic and safe for use in everyday consumer goods. It does not bioaccumulate and is largely inert.

However, regulatory bodies like the EU have classified inhaled TiO₂ particles as possibly carcinogenic in powdered form due to dust inhalation risks during manufacturing or processing. As a result, safe handling procedures and proper personal protective equipment (PPE) are important in industrial environments.

The Global Demand for Titanium Dioxide

The global market for titanium dioxide pigment continues to grow, driven by demand in Asia, the rise in construction activities, and expanding use in plastics and coatings. Major producers include companies like Chemours, Tronox, Kronos, and Chinese manufacturers such as CNNC Hua Yuan and Lomon Billions.

From plastics to papers, and from cosmetics to cars, the use of titanium dioxide shows no sign of slowing down. New innovations in surface treatments, nano-structured coatings, and sustainable production processes are also enhancing its value in high-performance and eco-friendly products.

In summary, titanium dioxide is not just a pigment — it’s a critical component in modern manufacturing and product development. Its combination of brightness, opacity, durability, and UV protection makes it indispensable across countless industries. Whether it's found in titanium dioxide paint or as raw titanium dioxide powder, its role as the most important white pigment remains undisputed.

As technology evolves and industries demand more sustainable and high-performance materials, the versatility and functionality of titanium dioxide will ensure its place at the forefront of innovation for decades to come.

-

Application of Titanium Dioxide 2195 in Water Purification

НавіныNov.14,2025

-

What are the global market trends of Titanox titanium dioxide in recent years

НавіныNov.14,2025

-

Effect of particle size distribution on the optical properties of R996 TiO2

НавіныNov.14,2025

-

Latest Technological Innovations in Rutile Titanium Dioxide Manufacturing

НавіныNov.14,2025

-

Compatibility of Titanium Dioxide Concrete Pigment with Different Concrete Admixtures

НавіныNov.14,2025

-

Environmental Impact of Titanium Dioxide Pigment Manufacturing and Mitigation Measures

НавіныNov.14,2025