чэрв . 11, 2025 10:13 Вярнуцца да спісу

Why Can't High-Quality Coatings Do Without Titanium Dioxide?

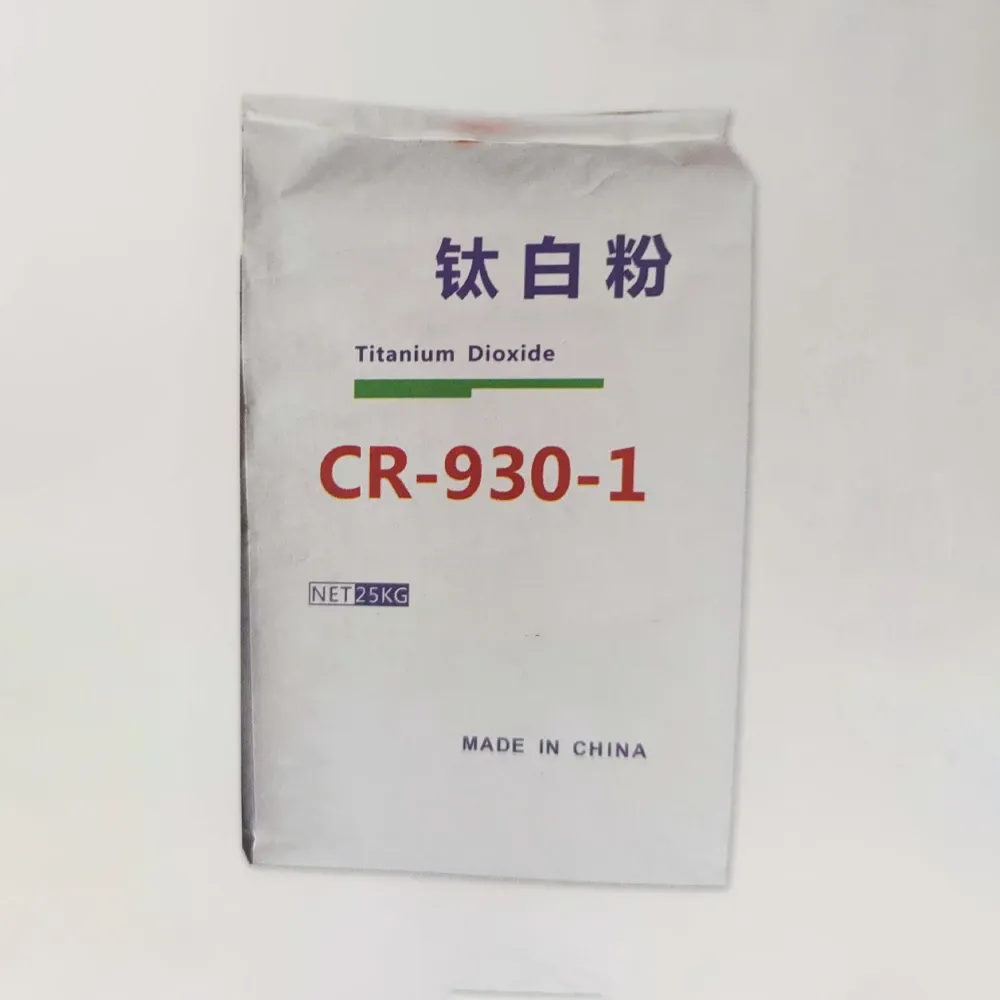

In the world of coatings and paints, titanium dioxide (TiO₂) is an indispensable ingredient. Whether it's пастаўшчыкі парашка дыяксіду тытана providing raw materials or manufacturers producing titanium dioxide paint coating, this compound plays a pivotal role in ensuring durability, brightness, and performance. High-quality coatings rely heavily on titanium dioxide pigment for opacity, UV resistance, and longevity. But why is this material so crucial? This article explores the science behind TiO₂ and its irreplaceable role in premium coatings.

The Science Behind Titanium Dioxide in Coatings

Exceptional Opacity and Whiteness

One of the primary reasons titanium dioxide coating is essential lies in its unmatched ability to provide opacity. TiO₂ has an extremely high refractive index (2.7 for rutile and 2.55 for anatase), far surpassing other white pigments like calcium carbonate or zinc oxide. This means that when light hits a titanium dioxide paint coating, the pigment scatters light efficiently, ensuring excellent coverage with minimal thickness.

Without TiO₂, coatings would require multiple layers to achieve the same hiding power, increasing material costs and application time. This is why titanium dioxide pigment is the go-to choice for high-end paints, where a smooth, even finish is non-negotiable.

UV Resistance and Durability

Another critical property of titanium dioxide coating is its ability to resist ultraviolet (UV) degradation. Many organic materials in paints break down under prolonged sun exposure, leading to chalking, fading, and structural weakening. However, TiO₂ acts as a UV absorber, protecting the binder system in coatings from photochemical damage.

This UV-blocking capability is particularly important in exterior applications, where titanium dioxide paint coating must withstand years of harsh weather conditions. Without TiO₂, coatings would degrade faster, requiring frequent repainting and maintenance.

The Role of Titanium Dioxide Powder Suppliers in Quality Control

Ensuring Purity and Consistency

Not all TiO₂ is created equal. The performance of titanium dioxide pigment depends heavily on its purity, particle size, and surface treatment. Reputable пастаўшчыкі парашка дыяксіду тытана ensure that their product meets stringent industry standards, as impurities can negatively affect opacity, gloss, and dispersibility.

For high-quality coatings, manufacturers rely on suppliers who provide finely milled, uniformly sized TiO₂ particles. This consistency ensures that the titanium dioxide paint coating delivers predictable performance, whether in architectural paints, automotive finishes, or industrial applications.

Advanced Surface Treatments

Modern titanium dioxide coating often incorporates surface treatments such as silica, alumina, or organic coatings to enhance dispersibility and weather resistance. Leading пастаўшчыкі парашка дыяксіду тытана offer specialized grades optimized for different applications—some for improved gloss in automotive paints, others for enhanced durability in marine coatings.

Without these tailored treatments, TiO₂ particles might clump together, reducing effectiveness and leading to uneven finishes. Thus, the expertise of suppliers directly impacts the final quality of the coating.

Environmental and Regulatory Considerations з Titanium Dioxide Powder

Balancing Performance and Sustainability

While TiO₂ is essential for high-performance coatings, its production has faced environmental scrutiny. The sulfate and chloride processes used to manufacture titanium dioxide pigment generate waste, prompting the industry to seek greener alternatives.

However, no other material currently matches TiO₂’s combination of opacity, durability, and cost-effectiveness. As a result, coating manufacturers continue to rely on пастаўшчыкі парашка дыяксіду тытана while investing in recycling and cleaner production methods.

Compliance with Safety Standards

Regulatory bodies such as the EPA and REACH have classified TiO₂ as a potential inhalation hazard in powder form. This has led to stricter handling protocols for пастаўшчыкі парашка дыяксіду тытана and coating manufacturers. Despite these concerns, when properly encapsulated in paint or coatings, TiO₂ poses minimal risk, making it a safe and effective choice for high-quality finishes.

Future Innovations in Titanium Dioxide Coatings

Nano-TiO₂ and Smart Coatings

Researchers are exploring nano-sized titanium dioxide pigment for next-generation coatings. These nanoparticles offer enhanced UV protection and even self-cleaning properties when exposed to sunlight. Such innovations could revolutionize titanium dioxide paint coating, making surfaces more resistant to dirt, bacteria, and pollution.

Alternatives and Hybrid Solutions

While TiO₂ remains irreplaceable for now, scientists are investigating partial substitutes like hollow glass spheres or advanced polymers to reduce dependency. However, these alternatives still fall short in terms of opacity and cost-efficiency, reinforcing TiO₂’s dominance in premium coatings.

From providing unmatched opacity to ensuring long-term durability, titanium dioxide coating is a cornerstone of high-quality paints and finishes. The reliability of пастаўшчыкі парашка дыяксіду тытана, combined with ongoing advancements in pigment technology, ensures that TiO₂ will remain indispensable for the foreseeable future. Whether in architectural, automotive, or industrial applications, titanium dioxide paint coating sets the standard for performance and longevity—proving that truly superior coatings cannot do without it.

-

Application of Titanium Dioxide 2195 in Water Purification

НавіныNov.14,2025

-

What are the global market trends of Titanox titanium dioxide in recent years

НавіныNov.14,2025

-

Effect of particle size distribution on the optical properties of R996 TiO2

НавіныNov.14,2025

-

Latest Technological Innovations in Rutile Titanium Dioxide Manufacturing

НавіныNov.14,2025

-

Compatibility of Titanium Dioxide Concrete Pigment with Different Concrete Admixtures

НавіныNov.14,2025

-

Environmental Impact of Titanium Dioxide Pigment Manufacturing and Mitigation Measures

НавіныNov.14,2025