Th12 . 03, 2024 16:54 Back to list

titanium dioxide uses factories

Titanium Dioxide Uses and Factories

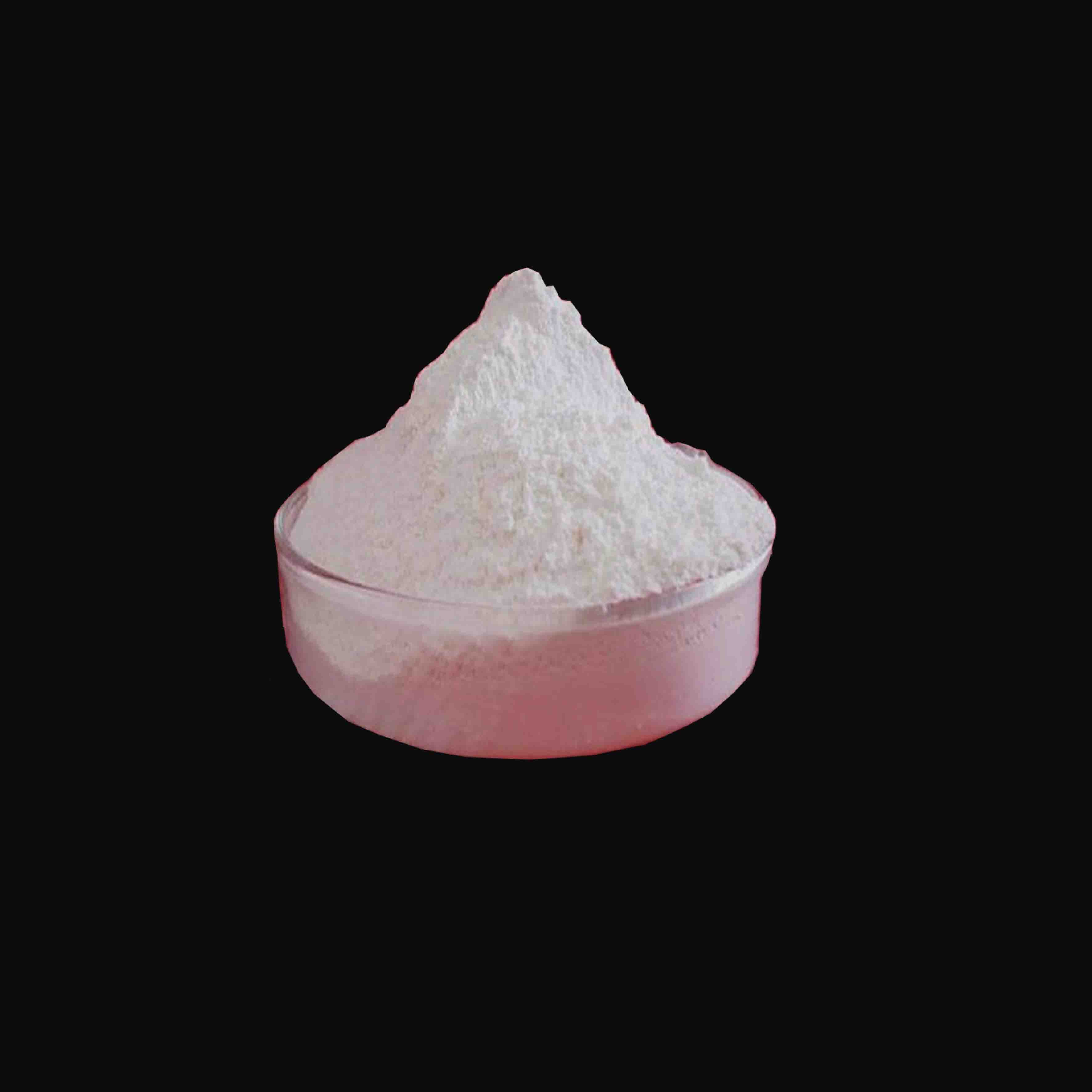

Titanium dioxide (TiO2) is a white, powdery substance that is widely used across many industries due to its unique properties, such as its brightness, high refractive index, and non-toxic nature. Initially discovered in the late 19th century, its commercial production began in the 20th century, and it has since become essential in numerous applications. The primary uses of titanium dioxide span various sectors, including paints, coatings, plastics, cosmetics, and even food.

One of the most significant applications of titanium dioxide is in the manufacture of paints and coatings. Its ability to provide excellent coverage and brightness makes it a preferred white pigment in the paint industry. TiO2 is known for its opacity, allowing it to cover underlying colors effectively, which results in a uniform finish. The durability and resistance to UV light also enhance the longevity of painted surfaces, making the products more appealing to consumers.

Titanium Dioxide Uses and Factories

Cosmetics and personal care products also utilize titanium dioxide extensively. It is commonly found in sunscreen formulations due to its ability to block harmful UV rays, protecting the skin from sun damage. Additionally, TiO2 is employed in makeup products, such as foundations and powders, to provide a bright, matte finish and enhance product stability. Its safety and effectiveness make it a favored ingredient among cosmetic manufacturers.

titanium dioxide uses factories

In the food industry, titanium dioxide is used as a coloring agent, often found in products such as candies, bakery goods, and dairy items. It provides a bright white color and improves the visual appeal of food products. However, the use of TiO2 in food has garnered scrutiny, and regulations vary across countries regarding its safety. This has led to ongoing discussions about the balance between consumer safety and product quality.

The process of manufacturing titanium dioxide primarily involves two methods the sulfate process and the chloride process. The sulfate process utilizes sulfuric acid to extract TiO2 from ilmenite ore, resulting in a material with a particular purity and quality. Conversely, the chloride process involves the conversion of titanium-bearing ores into titanium tetrachloride, which is then oxidized to produce TiO2. The chloride process generally yields a purer and more refined product, which is increasingly favored in high-performance applications.

The leading global producers of titanium dioxide include advanced factories located in various regions, including North America, Europe, and Asia. These factories are equipped with cutting-edge technology to ensure efficient production and to meet stringent environmental standards. Modern manufacturing plants utilize advanced processes that minimize waste and emissions, reflecting the industry's commitment to sustainability.

In conclusion, titanium dioxide plays a pivotal role across multiple industries due to its unique properties and versatility. From enhancing the quality of paints and plastics to ensuring the efficacy of sunscreen and food products, its applications are vast and varied. As the global demand for TiO2 continues to grow, so too does the responsibility of manufacturers to operate sustainably and ethically. The future of titanium dioxide looks promising, with ongoing research and innovation poised to expand its applications further while ensuring consumer safety and environmental protection.

-

Best Baso4 Price Wholesale & Manufacturer Deals in China

NewsApr.29,2025

-

Rutile Titanium Dioxide R698 Supplier Coating & Paint Solutions

NewsApr.29,2025

-

Premium Titanium Dioxide Ultra White Paint High-Coverage & Durable

NewsApr.29,2025

-

China Titanium & TiO2 Powder Factory Reliable Rutile & Lithopone Supplier

NewsApr.28,2025

-

Titanium Dioxide Types High-Purity Grades from Trusted Factories & Suppliers

NewsApr.28,2025

-

High-Quality Titanium Dioxide White Pigments Wholesale Supplier

NewsApr.28,2025