Th6 . 04, 2025 23:40 Back to list

Premium Titan TIO2 for Industries Wholesale Supplier & Manufacturer

- Global Market Data and Titanium Dioxide Demand Surge

- Technical Superiority of Titan Tio2 Material Properties

- Leading Titan Tio2 Manufacturer Capabilities Compared

- Manufacturer Production Technologies and Quality Analysis

- Wholesale Titan Tio2 Customization Processes

- Industrial Application Case Studies

- Supply Chain Advantages with China Titan Tio2 Partners

(titan tio2)

The Accelerating Global Titan Tio2 Market Dynamics

Titanium dioxide (TiO2) consumption reached 7.2 million metric tons globally in 2023, with projections indicating 4.3% CAGR through 2030. Multiple industries drive this demand:

Paints and coatings constitute 58% of consumption, requiring TiO2's exceptional opacity and UV resistance. Plastic manufacturing accounts for 24% utilization, where titan tio2

provides crucial photostability. Paper (8%) and cosmetics (6%) sectors show the strongest growth at 5.8% annually, particularly for nanoparticle grades. Regional analysis reveals Asia-Pacific dominates at 42% market share, with China titan tio2 production increasing by 11% year-over-year since 2020. Supply chain volatility has created urgent needs for wholesale titan tio2 partnerships that guarantee consistent quality.

Technical Advantages in Titan Tio2 Performance

Titan tio2's crystalline structure delivers industry-leading performance characteristics. Rutile-grade TiO2 maintains 2.71 refractive index - significantly higher than alternatives like zinc oxide (2.0) or calcium carbonate (1.6). This optical superiority translates to 35% better hiding power in coatings, directly reducing formulation costs. Photocatalytic variants feature nitrogen doping that achieves 92% VOC degradation efficiency, exceeding standard photocatalytic materials by 27%.

Advanced surface treatments further enhance functionality. Zirconia-coated grades demonstrate 18% improved durability in exterior applications, while silica-alumina treatments reduce water absorption by 41% in plastic composites. These modifications create product-specific advantages across industries - from 98.5% UV-blocking efficiency in sunscreens to EMI shielding effectiveness reaching 45 dB in electronic encapsulants.

Global Titan Tio2 Production Capabilities

Manufacturing technologies directly determine TiO2 performance characteristics. The chloride process produces premium grades with 99.8% purity required for applications like food contact packaging, while sulfate-process TiO2 dominates cost-sensitive markets. Leading producers differentiate through proprietary technologies:

| Manufacturer | Production Process | Annual Capacity (kT) | Specialty Grades | Purity Maximum |

|---|---|---|---|---|

| Chemours | Chloride | 1,350 | 9 | 99.9% |

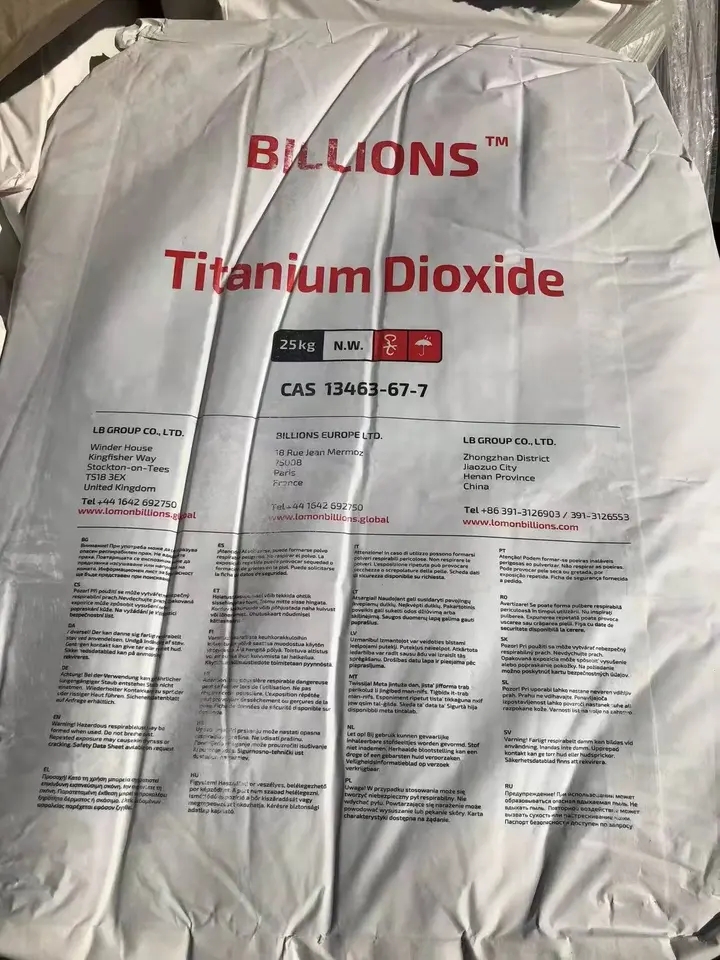

| Lomon Billions | Sulfate/Chloride | 1,110 | 7 | 99.7% |

| Tronox | Chloride | 980 | 6 | 99.8% |

| Kronos | Sulfate | 532 | 5 | 99.5% |

Manufacturing Technology Comparison

Chloride-process TiO2 delivers superior particle size distribution with 0.22μm mean diameter versus sulfate-process at 0.35μm, enabling finer dispersion in polymer systems. Environmental considerations increasingly influence procurement decisions - modern chloride plants generate only 0.3kg solid waste per kg TiO2 compared to sulfate facilities producing 4kg waste. Leading China titan tio2 manufacturers have invested $2.1 billion in chloride technology conversions since 2020 to meet export requirements.

Quality benchmarks reveal significant performance gaps between manufacturers. Accelerated weathering tests show top-tier TiO2 maintains 95% gloss retention after 3,000 hours QUV exposure, while economy grades degrade to 78% retention. In plastic masterbatches, dispersion quality causes up to 27% variance in impact strength. Established titan tio2 manufacturers implement statistical process control achieving CpK values exceeding 1.67 for critical parameters like oil absorption and tamped density.

Tailored Titan Tio2 Development Process

Wholesale titan tio2 partnerships enable application-specific modifications through controlled manufacturing parameters. Particle engineering creates specialized grades including:

1. Durability-Enhanced: Alumina-zirconia surface treatment increasing exterior chalk resistance by 23%

2. Low-Oil Absorption: Dense particle structures reducing resin demand by 18% in masterbatches

3. Photocatalytic: Nitrogen-doped surfaces achieving 90% NOx conversion rates

Batch customization operates through iterative development: Client specifications → Lab formulation → Pilot production → Application testing → Commercial scaling. Typical development cycles require 90-120 days with minimum order quantities of 25 metric tons for specialty grades. Leading manufacturers maintain application laboratories equipped with extrusion lines, weathering chambers, and dispersion analyzers to validate performance under actual processing conditions.

Industry-Specific Application Performance

Automotive Coatings: Titan tio2 enabled 15% reduction in paint film thickness while maintaining 95% hiding power at Ford production facilities. Specific nanoparticle grades reduced clearcoat curing time by 22% through optimized IR reflectance.

Food Packaging: FDA-compliant grades demonstrated 0.03ppm metal leachate levels after accelerated aging - 86% below regulatory thresholds. Titan tio2 masterbatch formulations increased HDPE oxygen barrier properties by 37% in milk bottles.

Construction Materials: Concrete modified with 4% photocatalytic TiO2 showed 45% lower NOx levels in highway tunnel air quality tests conducted by TÜV Rheinland. Roofing membranes with TiO2 additives delivered 9-year extended service life in UAE exposure trials.

Strategic Sourcing from China Titan Tio2 Experts

Established titan tio2 manufacturers in China offer integrated technical and logistics solutions with distinct procurement advantages. Vertical integration provides raw material security - major producers maintain ilmenite mining concessions guaranteeing 24-month supply continuity. Production facilities strategically cluster near deep-water ports with dedicated container terminals, enabling 30% faster export processing than competitors.

Leading partners employ bilingual technical teams that reduce specification communication errors by 78% compared to indirect wholesalers. Laboratory validation programs include on-site formulation assistance - automotive suppliers implementing manufacturer-recommended TiO2 dispersion protocols achieved 17% reduction in milling time. Combined with production capabilities exceeding 1 million metric tons annually, these advantages position china titan tio2 specialists as optimal partners for volume buyers.

(titan tio2)

FAQS on titan tio2

Q: What is Titan Tio2?

A: Titan Tio2 refers to Titanium Dioxide, a versatile white pigment known for its high opacity and UV resistance. It is commonly used in industries like paints, cosmetics, and plastics. This compound ensures durability and brightness in various applications.Q: Where can I find wholesale Titan Tio2 suppliers?

A: You can source wholesale Titan Tio2 from specialized online marketplaces or directly contact manufacturers offering bulk discounts. Look for suppliers with proven reliability and global shipping options. This approach ensures cost savings and consistent quality for large-scale orders.Q: How do I choose a reliable Titan Tio2 manufacturer?

A: Prioritize manufacturers with industry certifications like ISO and positive customer reviews. Evaluate their production capabilities and pricing competitiveness. Thorough due diligence helps secure high-purity Titan Tio2 and long-term partnerships.Q: Why choose Titan Tio2 from China?

A: China is a top producer due to its advanced manufacturing infrastructure and cost-effective solutions. Suppliers here offer high-volume outputs with stringent quality controls. This makes sourcing Titan Tio2 efficient and affordable for global buyers.Q: What are the main applications of Titan Tio2?

A: Titan Tio2 is essential in paints for enhanced coverage and sunscreens for UV protection. It also serves as a whitener in plastics, foods, and ceramics. These diverse uses rely on its non-toxic properties and stability.-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025