Th12 . 31, 2024 13:44 Back to list

tio2 equipment suppliers

The Role of TiO2 Equipment Suppliers in the Industrial Ecosystem

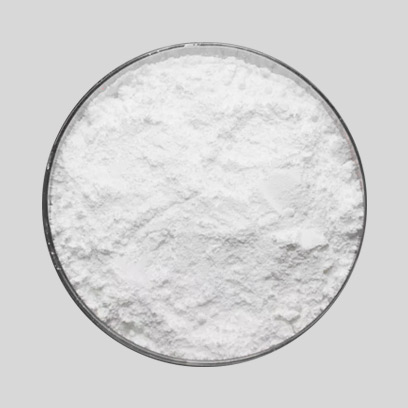

Titanium dioxide (TiO2) is a versatile material extensively used in numerous industries, including paints, coatings, plastics, and cosmetics. Its remarkable properties, such as high refractive index and excellent UV resistance, make it an essential component in these sectors. As the demand for TiO2 continues to rise globally, the role of TiO2 equipment suppliers becomes increasingly crucial in ensuring efficient production processes and maintaining high-quality standards.

Understanding the TiO2 Market

The titanium dioxide market has been expanding due to growing industrial applications and the increasing need for sustainable and effective materials. With the rise in demand for eco-friendly products, many companies are now exploring innovative ways to utilize TiO2, particularly in green technology applications, such as photocatalysis and solar energy. Consequently, TiO2 equipment suppliers must remain at the forefront of technological advancements to support these evolving market needs.

The Importance of Quality Equipment

The equipment used in the production of titanium dioxide significantly influences the quality of the final product. TiO2 is typically produced through two primary processes the sulfate process and the chloride process. Each of these methods requires specialized equipment tailored to the specific production method. For instance, the sulfate process utilizes reactors, filters, and precipitation tanks, whereas the chloride process requires chlorination units and high-temperature reactors. Suppliers of this equipment not only provide the machinery but also often offer technical support and maintenance services, ensuring optimal performance.

Innovations in TiO2 Production Equipment

In recent years, there has been significant innovation within the TiO2 equipment sector. Modern equipment is being designed with improved energy efficiency and reduced environmental impact in mind. Suppliers are increasingly incorporating automation and advanced control systems into their machinery to enhance production efficiency and product consistency. Technologies such as IoT (Internet of Things) are being utilized to monitor production processes in real time, enabling suppliers to respond swiftly to any deviations from optimal performance.

tio2 equipment suppliers

Moreover, some suppliers are investing in research and development to create equipment that minimizes waste and lowers operational costs. These advancements not only benefit TiO2 manufacturers by improving their bottom line but also contribute to sustainability efforts by reducing the industry's overall carbon footprint.

Selecting the Right Supplier

When it comes to selecting a TiO2 equipment supplier, manufacturers should consider several factors. First, the supplier's experience and reputation in the industry play a vital role. A well-established supplier with a good track record is likely to offer more reliable equipment and effective after-sales support. Additionally, companies should assess the range of products offered, as some suppliers may specialize in specific types of equipment while others provide comprehensive solutions.

Technical support and service availability are also critical considerations. A supplier that offers ongoing assistance and maintenance services can help manufacturers manage downtime and ensure that their operations run smoothly. Furthermore, looking for suppliers that emphasize customization may lead to better alignment between a manufacturer’s specific needs and the supplied equipment.

The Future of TiO2 Equipment Suppliers

As the TiO2 market continues to evolve, suppliers will need to adapt to meet changing customer demands and regulatory requirements. The trend towards greener production methods is likely to persist, prompting suppliers to innovate further in energy-efficient and environmentally friendly equipment. Moreover, as global competition intensifies, suppliers who can offer not only cutting-edge technology but also comprehensive support and services will likely thrive.

In conclusion, TiO2 equipment suppliers play an essential role in the success of the titanium dioxide industry. By providing high-quality equipment, innovative technologies, and ongoing support, these suppliers contribute significantly to the efficiency and sustainability of TiO2 production. As the market continues to grow and evolve, the partnership between manufacturers and their equipment suppliers will be crucial in shaping the future landscape of titanium dioxide applications.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025