Th12 . 20, 2024 08:03 Back to list

rutile titanium dioxide for water base coating manufacturers

The Role of Rutile Titanium Dioxide in Water-Based Coatings Manufacturing

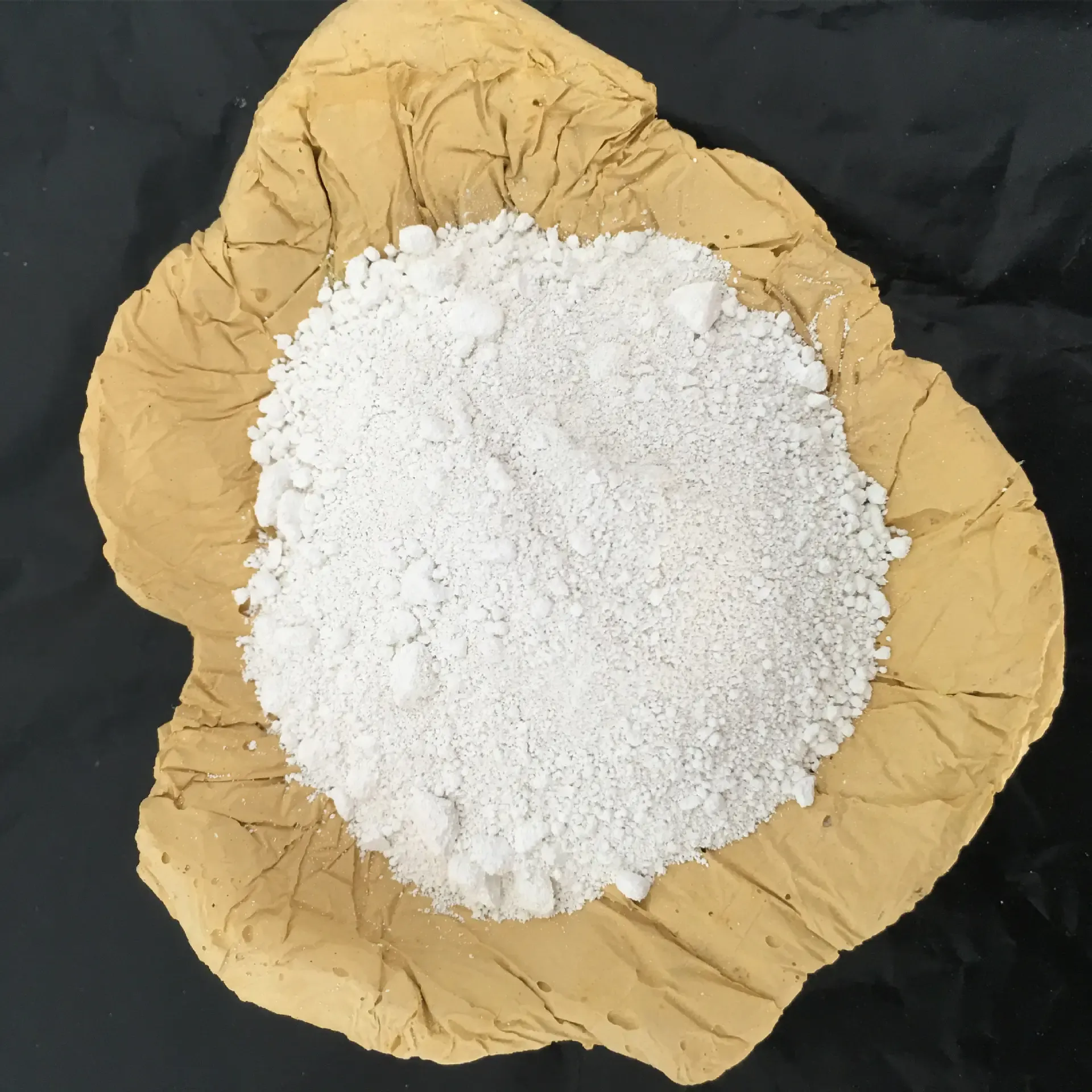

Rutile titanium dioxide (TiO2) has become an essential component in the production of water-based coatings, largely due to its exceptional properties, which include high opacity, brightness, and UV resistance. As the demand for environmentally friendly and sustainable products continues to rise, the use of water-based coatings has gained significant traction. This shift in consumer preference is reshaping the landscape for manufacturers, who must adapt by incorporating high-quality raw materials like rutile titanium dioxide.

Understanding Rutile Titanium Dioxide

Rutile is one of the three primary forms of titanium dioxide, the other two being anatase and brookite. Known for its high refractive index and superior pigmenting properties, rutile is the preferred choice for coatings manufacturers. When used in water-based formulations, rutile TiO2 offers excellent dispersion capabilities, ensuring uniform application and consistent finish. Its chemical stability also provides durability, making it suitable for various applications including architectural, industrial, and decorative coatings.

Benefits of Water-Based Coatings

Water-based coatings have several advantages over their solvent-based counterparts. They are low in volatile organic compounds (VOCs), making them significantly less harmful to both human health and the environment. Moreover, these coatings have faster drying times and less odor, which can enhance the user's experience during application. The incorporation of rutile titanium dioxide into these formulations not only maintains the ecological benefits but also enhances performance, as the pigment contributes to improved opacity, hiding power, and longevity.

The Manufacturing Process

The process of manufacturing water-based coatings with rutile titanium dioxide involves several steps. First, the titanium dioxide is carefully processed to ensure that it meets the strict quality standards required for coatings. After this, it is blended with other materials such as resins, additives, water, and other pigments. Achieving the right balance of properties is crucial—too much water can dilute the pigment, while insufficient resins may compromise the coating’s durability.

rutile titanium dioxide for water base coating manufacturers

Uniform dispersion of rutile TiO2 is a critical factor in creating a high-quality coating. Modern manufacturing techniques often utilize advanced milling and mixing equipment to achieve optimal particle size and distribution, which ultimately influences the performance of the final product. The formulation must also be tested rigorously to ensure it meets the required specifications for viscosity, opacity, and adhesion.

Market Trends and Innovations

The coatings industry is witnessing continuous innovation, driven by technological advancements and a growing emphasis on sustainability. As a result, manufacturers are exploring new methods to enhance the performance of rutile titanium dioxide in water-based coatings. Innovations such as using surface treatments like silane or alumina coatings help improve dispersion stability and reduce agglomeration, further enhancing the efficacy of TiO2 in formulations.

Moreover, the market is seeing a shift toward hybrid systems that combine the benefits of both water-based and solvent-based coatings. These hybrids leverage the unique properties of rutile titanium dioxide while meeting stricter environmental regulations. The integration of nano-sized TiO2 particles is also being explored, offering improved functionality and reduced dosage requirements, thereby minimizing costs and enhancing sustainability.

Challenges Ahead

Despite the numerous advantages of using rutile titanium dioxide in water-based coatings, manufacturers face certain challenges. The fluctuating raw material prices and the increasing costs of compliance with environmental regulations can put pressure on profit margins. Additionally, the performance of water-based coatings can be influenced by factors such as temperature and humidity, which manufacturers must carefully consider during production.

Conclusion

Rutile titanium dioxide plays a pivotal role in the formulation of high-quality water-based coatings. Its unique properties provide manufacturers with the means to produce environmentally friendly, durable, and aesthetically pleasing products. As the demand for sustainable solutions continues to grow, the integration of rutile TiO2 in coatings will not only meet market requirements but also support the industry’s transition towards a more sustainable future. By overcoming the existing challenges and embracing innovations, manufacturers can continue to thrive in this evolving marketplace.

-

Best Baso4 Price Wholesale & Manufacturer Deals in China

NewsApr.29,2025

-

Rutile Titanium Dioxide R698 Supplier Coating & Paint Solutions

NewsApr.29,2025

-

Premium Titanium Dioxide Ultra White Paint High-Coverage & Durable

NewsApr.29,2025

-

China Titanium & TiO2 Powder Factory Reliable Rutile & Lithopone Supplier

NewsApr.28,2025

-

Titanium Dioxide Types High-Purity Grades from Trusted Factories & Suppliers

NewsApr.28,2025

-

High-Quality Titanium Dioxide White Pigments Wholesale Supplier

NewsApr.28,2025