Th8 . 22, 2024 01:46 Back to list

Exploring Local Suppliers for Titanium Dioxide Procurement Options and Strategies

The Dynamics of Titanium Dioxide Purchase and the Role of Factories in the Supply Chain

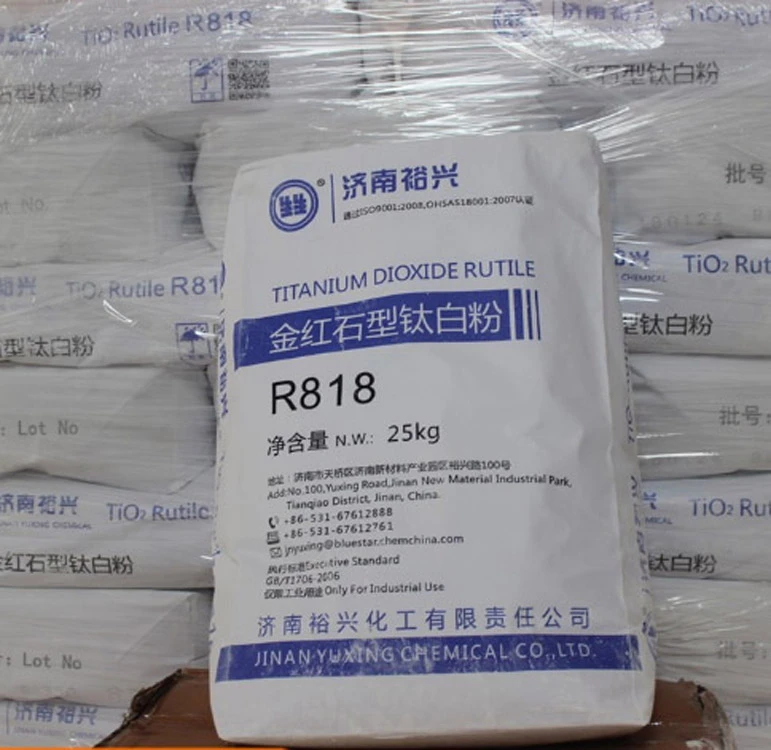

Titanium dioxide (TiO2) is widely recognized as one of the most important chemical compounds used across diverse industries. Its application ranges from paint, coatings, and plastics to food coloring and cosmetics. Given its versatility, the purchase of titanium dioxide from various factories has become a critical aspect of many businesses aiming to maintain competitive advantages in their respective markets.

Understanding the purchasing dynamics of titanium dioxide begins with recognizing the key players in the supply chain. Factories that produce TiO2 utilize various methods, predominantly the sulfate process and the chloride process, to manufacture this essential compound. Each method has its unique advantages and production conditions, which influence the quality and cost of the titanium dioxide produced.

The Dynamics of Titanium Dioxide Purchase and the Role of Factories in the Supply Chain

Purchasing titanium dioxide involves several critical factors. One of the most significant considerations is the quality of the product. Industries that use TiO2 as a pigment, such as the paint and coatings sector, require pigments that meet specific color and opacity standards. Therefore, many buyers conduct rigorous quality assessments before finalizing their orders. This often involves sourcing samples, conducting laboratory tests, and even site visits to the factories producing the material.

titanium dioxide purchase factories

Cost is another important factor influencing the purchasing decision. Titanium dioxide prices can fluctuate based on global supply and demand dynamics, production costs, and geopolitical factors. As a result, buyers must establish strategic relationships with multiple suppliers to mitigate risks associated with price volatility. Engaging with factories directly can sometimes lead to cost savings, as manufacturers often offer better pricing for bulk purchases or long-term contracts.

Furthermore, sustainability concerns are becoming increasingly relevant in the purchasing decisions of businesses. Many factories now focus on adopting eco-friendly practices in their production processes, which include reducing waste and energy consumption. Buyers are more inclined to partner with suppliers who demonstrate a commitment to sustainability. This shift not only aligns with ethical business practices but also enhances brand value and consumer trust.

In addition to these considerations, geographical factors play a crucial role in titanium dioxide procurement. Factories located near raw material sources or major transportation hubs often have cost advantages. This geographical positioning impacts the logistics of purchasing, as transportation costs can significantly influence the overall price of titanium dioxide.

In conclusion, the purchase of titanium dioxide from factories involves a complex interplay of factors, including quality, cost, sustainability, and logistics. As industries continue to evolve, the demand for high-quality titanium dioxide will likely grow. Companies looking to secure a competitive edge must strategically navigate this supply chain, forming strong relationships with reliable manufacturers while addressing the challenges posed by market fluctuations and environmental concerns. By doing so, they can leverage the essential qualities of titanium dioxide to enhance their product offerings and drive sustainable growth.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025