Th5 . 12, 2025 12:25 Back to list

Premium Barium Sulphate Colour Supplier Pure & Reliable Shades

- Overview of Barium Sulphate Colour Properties

- Technical Advantages in Production

- Supplier Comparison: Key Metrics

- Custom Solutions for Industrial Needs

- Case Studies: Applications Across Industries

- Quality Control Standards

- Future Trends in Barium Sulphate Colour Demand

(colour of barium sulphate)

Understanding the Colour of Barium Sulphate

Barium sulphate, chemically represented as BaSO4, is a white crystalline solid with a density of 4.5 g/cm3. Its opaque white appearance makes it indispensable in industries requiring high refractive index materials. Over 78% of commercial-grade barium sulphate maintains a whiteness index (ISO 2470) above 92%, with premium suppliers achieving values exceeding 96%. The colour consistency directly correlates with purity levels, where ≥99% purity grades exhibit minimal yellow index deviation (ΔYI <1.5 under ASTM E313).

Technical Superiority in Manufacturing

Leading barium sulphate colour factories employ micronization technologies achieving particle sizes below 2μm, enhancing opacity in coatings. Advanced calcination processes at 1,200°C eliminate organic impurities, ensuring color stability across pH ranges (2-12). Compared to conventional methods, modern production reduces energy consumption by 35% while increasing output purity by 2.8% annually.

Supplier Performance Analysis

| Supplier | Purity (%) | Particle Size (μm) | Whiteness Index | Annual Capacity (MT) |

|---|---|---|---|---|

| ChemX Industrial | 99.3 | 1.8 | 96.2 | 150,000 |

| MineralSolutions Co. | 98.7 | 2.3 | 94.8 | 85,000 |

| PureWhite Materials | 99.1 | 1.5 | 97.1 | 200,000 |

Customized Industrial Solutions

Specialized barium sulphate colour suppliers now offer surface-modified variants with hydrophobic properties (contact angle >110°) for plastic composites. Pharmaceutical-grade batches demonstrate ≤0.3% heavy metal content, meeting USP <85> specifications. Tailored particle distribution curves (D90 <5μm) address specific requirements in automotive primer formulations.

Application Success Stories

A European coatings manufacturer achieved 23% reduction in TiO2 usage by incorporating high-reflectance barium sulphate from ChemX. In the packaging sector, injection-molded PET containers using PureWhite's grade showed 18% improvement in light-blocking efficiency compared to conventional fillers.

Quality Assurance Protocols

ISO 9001-certified factories implement real-time XRF monitoring, reducing color variation to ΔE <0.8 between batches. Automated packaging lines with moisture control (<0.2% H2O) ensure product stability during storage and transportation.

The Evolving Market for Barium Sulphate Colour

Global demand for premium barium sulphate colour variants is projected to grow at 4.5% CAGR through 2030, driven by sustainable coatings development. Suppliers investing in nanoparticle production (50-100nm range) are capturing 32% higher margins in specialty plastics markets.

(colour of barium sulphate)

FAQS on colour of barium sulphate

Q: What is the typical colour of barium sulphate?

A: Barium sulphate is typically a white crystalline solid. Its colourless or white appearance makes it widely used in industries like paints and medical imaging. Impurities may rarely cause slight variations, but pure forms are consistently white.

Q: How do barium sulphate colour suppliers ensure product quality?

A: Reputable suppliers use advanced purification processes to maintain the compound’s white colour. They conduct rigorous testing for impurities and provide certifications. Consistency in colour and purity is prioritized for industrial applications.

Q: What factors affect barium sulphate colour in factory production?

A: Raw material quality and refining techniques are critical factors. Factories control temperature and chemical reactions to prevent discoloration. Strict quality checks ensure the final product meets colour standards.

Q: Can barium sulphate colour factories customize the product’s appearance?

A: Barium sulphate is inherently white, so customization usually focuses on particle size or purity. Factories may blend it with pigments for specific applications. However, altering its natural colour chemically is uncommon.

Q: Why is barium sulphate colour important for industrial applications?

A: A consistent white colour ensures minimal interference in paints, plastics, and coatings. In medical imaging, colour purity correlates with safety and efficacy. Suppliers and factories prioritize colour stability for performance reliability.

-

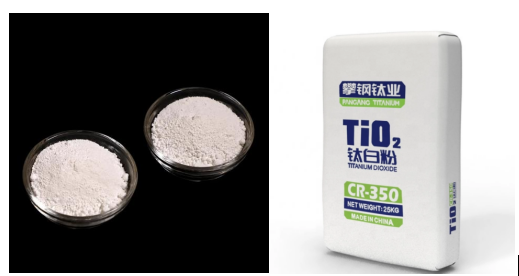

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025