พ.ย. . 07, 2024 13:05 Back to list

Bulk Coating Raw Material for Industrial Applications and Supply Solutions

Wholesale Coating Raw Materials A Comprehensive Overview

The global coatings industry plays a crucial role in various sectors, including automotive, aerospace, construction, and consumer goods. At the heart of this industry is the procurement of raw materials, which serve as the foundation for manufacturing high-quality coatings. This article aims to explore the significance of wholesale coating raw materials, their types, sourcing strategies, and their impact on the overall coatings market.

Importance of Coating Raw Materials

Coating raw materials are essentially the building blocks of finished products. They include pigments, resins, solvents, and additives, each contributing unique properties to the final formulation. For example

- Pigments provide color and opacity, essential for both aesthetic and functional purposes. - Resins act as the binder that holds the coating together, influencing adhesion, durability, and chemical resistance. - Solvents are used to dissolve resins and adjust the consistency of the mixture, making application easier. - Additives enhance specific attributes such as UV resistance, anti-microbial properties, or anti-foaming capabilities.

The selection of these materials significantly affects the performance, durability, and applicability of the coatings, making it crucial for manufacturers to source them wisely.

Types of Coating Raw Materials

The diversity of coating raw materials is immense, but they can be broadly categorized into two groups water-based and solvent-based materials.

1. Water-Based Coating Raw Materials These materials represent an eco-friendly option, having lower levels of volatile organic compounds (VOCs). Common water-based materials include acrylics, alkyds, and latex resins. The growing emphasis on sustainability and environmental responsibility has led to an increased demand for water-based coatings across various industries.

2. Solvent-Based Coating Raw Materials These materials generally provide superior performance characteristics, such as enhanced durability and resistance to harsh environments. However, they often contain higher levels of VOCs. Key examples include alkyd resins and solvent-based paints, which are widely used in industrial applications.

Sourcing Strategies for Wholesale Coating Raw Materials

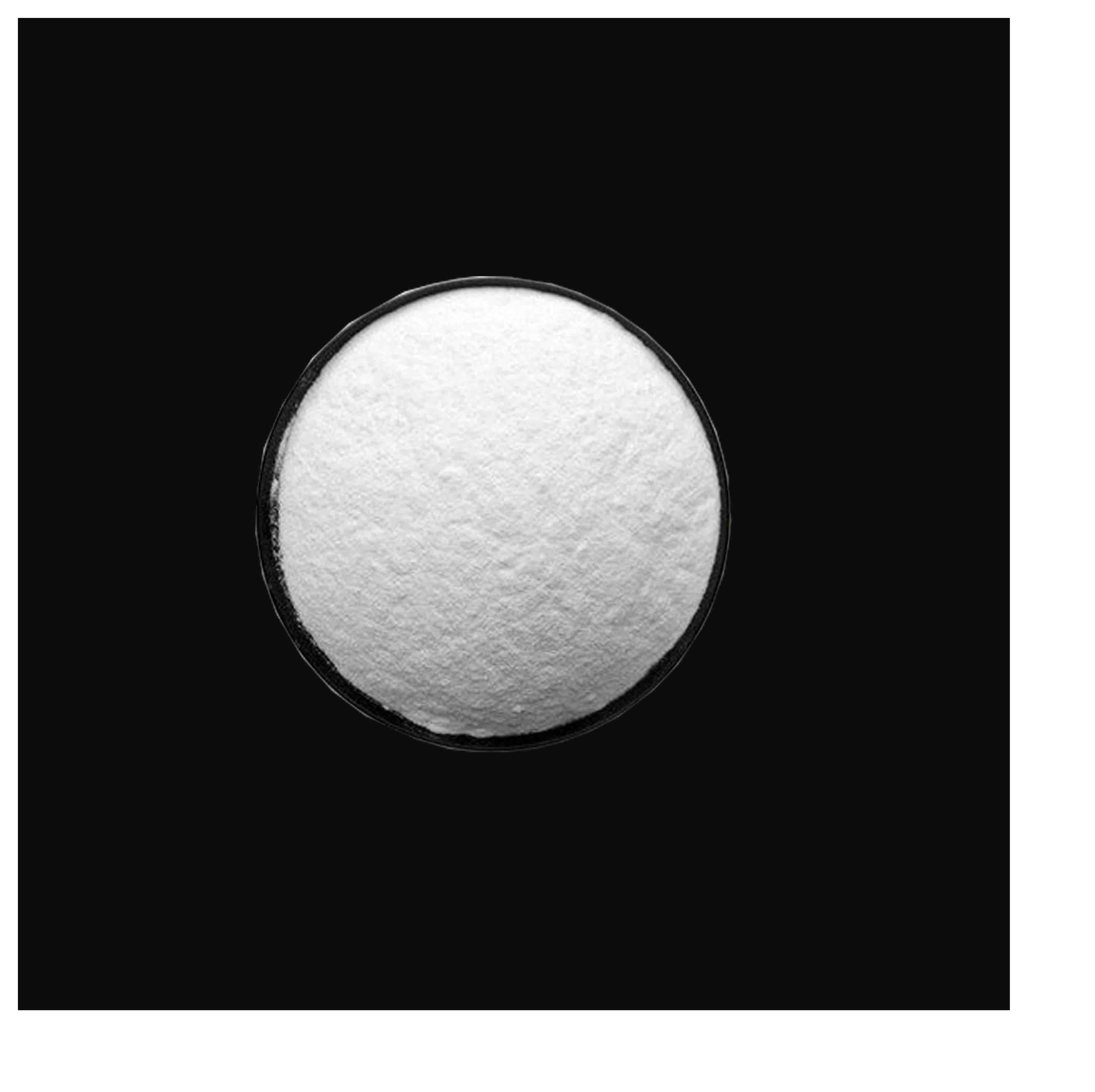

wholesale coating raw material

For manufacturers aiming to optimize their production processes and maintain competitive pricing, effective sourcing strategies for wholesale coating raw materials are paramount. Here are some key strategies

- Building Strong Supplier Relationships Establishing long-term partnerships with reliable suppliers can ensure consistent quality and availability of raw materials. Regular communication and collaboration can lead to better pricing and favorable terms.

- Global Sourcing The global market offers a wide array of raw material options. By looking beyond local suppliers, manufacturers can tap into competitive pricing and specialized products that may not be available domestically.

- Staying Updated on Market Trends Understanding market dynamics and trends can help manufacturers anticipate changes in material availability and pricing. For instance, fluctuations in crude oil prices can directly impact solvent-based raw materials, making it crucial for companies to stay informed.

- Investing in Research and Development Developing new formulations and investing in R&D can lead to the creation of innovative coatings that meet changing consumer demands. This proactive approach can also result in better sourcing decisions based on specific performance requirements.

Impact on the Coatings Market

The sourcing and utilization of wholesale coating raw materials significantly influence the overall coatings market. Supply chain disruptions can lead to increased costs and longer lead times, impacting production schedules. Additionally, the shift toward sustainable materials is forcing companies to evolve their sourcing strategies and product offerings.

Moreover, investment in advanced machinery and technology for the processing of raw materials is crucial for manufacturers aiming to enhance efficiency and reduce waste. This not only benefits the bottom line but also aligns with global sustainability efforts.

Conclusion

The role of wholesale coating raw materials in the coatings industry cannot be overstated. They are integral to achieving desired product characteristics and performance. As the industry continues to evolve, focusing on sustainable practices, building robust supplier relationships, and adapting to market changes will be vital for manufacturers. By prioritizing these aspects, companies can position themselves for success and navigate the complexities of the coatings market effectively.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025