พ.ย. . 12, 2024 18:38 Back to list

titanium dioxide is a precipitate manufacturer

The Role of Titanium Dioxide as a Precipitate Manufacturer

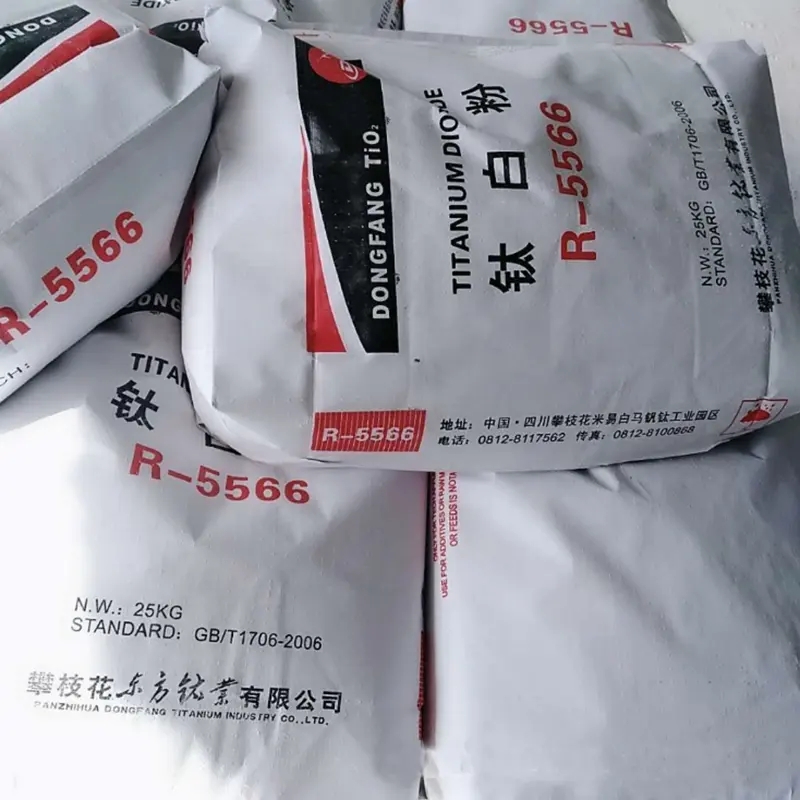

Titanium dioxide (TiO2) is a versatile compound widely recognized for its applications in various industries, particularly in pigments, photocatalysts, and UV filters. Its unique properties, such as high opacity, non-toxic nature, and exceptional brightness, make it an ideal candidate for several manufacturing processes. Among these processes, the production of titanium dioxide as a precipitate has garnered significant attention. This article explores the methods of titanium dioxide precipitation and its implications for different sectors.

Understanding Titanium Dioxide Precipitation

Precipitation is a process where dissolved substances crystallize from a solution, resulting in the formation of solid particles. In the context of titanium dioxide, precipitation typically involves the transformation of titanium salts into TiO2 through chemical reactions. The most common methods for precipitating titanium dioxide include the sulfate process and the chloride process.

The sulfate process involves the reaction of sulfuric acid with titanium ore, resulting in the formation of titanyl sulfate, which can be further hydrolyzed to yield titanium dioxide precipitate. In contrast, the chloride process entails the reaction of titanium ores with chlorine at high temperatures, producing titanium tetrachloride, which is then oxidized to form titanium dioxide. Both methods have their advantages and drawbacks, with the choice largely depending on the desired quality and application of the final product.

Applications of Precipitated Titanium Dioxide

1. Pigment Industry One of the most significant applications of precipitated titanium dioxide is in the pigment industry. Due to its excellent light-scattering properties, TiO2 acts as a white pigment in paints, coatings, and plastics. It enhances the brightness and opacity of products, ensuring vibrant colors and effective coverage. The demand for high-quality white pigments continues to rise, driving the need for advanced precipitation techniques that yield TiO2 with superior characteristics.

titanium dioxide is a precipitate manufacturer

2. Catalysts The photocatalytic properties of titanium dioxide make it an essential component in environmental technologies. Precipitated TiO2 is used in photocatalysts for applications such as air and water purification. The ability of TiO2 to degrade organic pollutants when exposed to UV light is particularly valuable in reducing environmental contaminants. As a precipitate manufacturer, producing high-purity TiO2 is crucial for the effectiveness and durability of these catalysts.

3. Cosmetics and Sunscreens Titanium dioxide is a common ingredient in cosmetic formulations, especially in sunscreens. Its role as a UV filter helps protect the skin from harmful solar radiation. The precipitated form of TiO2 is preferred for its finer particle size, which enhances the cosmetic feel and effectiveness of sunscreen products. This has led to an increased demand for specialized manufacturing processes that produce TiO2 suitable for cosmetic applications.

4. Food Industry Interestingly, TiO2 is also utilized in the food industry as a food additive, primarily for its coloring properties. However, the use of titanium dioxide in food products is under scrutiny due to potential health concerns, prompting manufacturers to ensure that their precipitated TiO2 complies with safety regulations.

Challenges and Future Perspectives

Despite its extensive applications, the titanium dioxide industry faces several challenges. Environmental regulations around mining and production are becoming increasingly stringent, necessitating a shift towards more sustainable manufacturing practices. Additionally, the health implications of TiO2 in various applications, particularly in food and cosmetics, have ignited debates about its safety and prompted research into alternative compounds.

Looking forward, the innovation in titanium dioxide production will likely focus on enhancing the efficiency of precipitation methods while minimizing environmental impact. Advances in nanotechnology and green chemistry could lead to the development of novel TiO2 forms with tailored properties for specific applications, further expanding its utility across various sectors.

In conclusion, titanium dioxide as a precipitate manufacturer plays a crucial role in numerous industries, contributing to advancements in pigments, catalysts, cosmetics, and beyond. As the demand for sustainable and high-quality materials continues to grow, the industry must adapt and innovate, ensuring that precipitated titanium dioxide remains a vital component in the global market.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025