ธ.ค. . 05, 2024 17:16 Back to list

TiO2 Sourcing Strategies for Manufacturing and Supply Chain Efficiency

Understanding TiO2 Procurement in the Industry

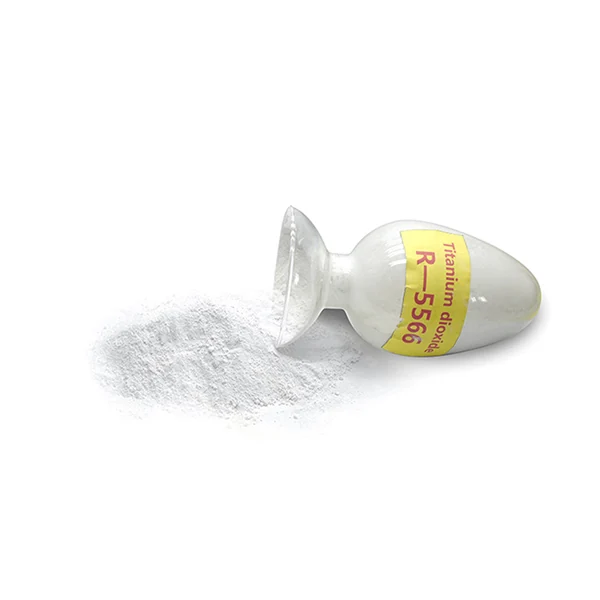

Titanium dioxide (TiO2) is one of the most widely used white pigments in various industries, including paints, coatings, plastics, and papers. Its unique properties, such as high opacity and excellent UV resistance, make it indispensable for ensuring the quality and longevity of products. However, the procurement of TiO2 can be a complex process, influenced by factors such as supply chain dynamics, production capabilities, and technological advancements. This article delves into the intricacies of TiO2 procurement and its significance in industrial applications.

The Importance of Titanium Dioxide

TiO2 is primarily used as a pigment due to its bright whiteness and high refractive index. It accounts for a significant portion of the global pigment market, valued at several billion dollars. Beyond its use in various colors and finishes, TiO2 serves functional purposes, including UV protection and photocatalytic properties. This versatility highlights the necessity for consistent and reliable procurement strategies to ensure that industries can meet their production demands while maintaining product quality.

Procurement Strategies

When it comes to TiO2 procurement, companies must adopt a comprehensive strategy. The first step involves identifying reliable suppliers that consistently produce high-quality material. Factors to consider when selecting suppliers include production capacity, sustainability practices, and adherence to industry standards. A supplier's geographic location is also crucial, as it impacts shipping costs and time.

Additionally, companies should conduct thorough market research to understand pricing trends and availability. The pricing of TiO2 can fluctuate based on various factors, including raw material costs, regulatory changes, and global demand. By staying informed about market conditions, businesses can negotiate better contracts and terms with suppliers.

Supply Chain Considerations

tio2 procurement factory

The supply chain for TiO2 procurement is complex and can significantly impact costs and delivery times. Manufacturers often source raw materials from different parts of the world, creating a need for strategic logistics management. Disruptions in the supply chain, such as transportation delays, geopolitical issues, or natural disasters, can affect the availability of TiO2. Therefore, companies must develop contingency plans to mitigate risks, such as identifying alternative suppliers or increasing inventory levels.

Sustainability is also becoming a significant factor in the procurement of TiO2. With increasing regulations around environmental impact, companies are under pressure to source materials responsibly. Many suppliers are striving to adopt more sustainable practices, such as minimizing waste and reducing carbon emissions in the production process. Therefore, businesses should assess potential suppliers not only based on cost and reliability but also on their commitment to sustainability.

Technological Advancements

Technological advancements are continually transforming how TiO2 is produced and procured. Innovations in manufacturing processes are enabling suppliers to increase efficiency and reduce costs, providing opportunities for buyers to benefit from lower prices and improved product quality. Additionally, advancements in analytical technologies can help businesses better assess the quality of TiO2, ensuring that they source materials that meet their stringent requirements.

Emerging technologies, such as artificial intelligence and machine learning, are also starting to play a role in the procurement process. These technologies can help businesses analyze market trends, predict price fluctuations, and optimize their inventory management systems. By leveraging these tools, companies can enhance their procurement strategies and improve overall operational efficiency.

Conclusion

TiO2 procurement is a critical aspect of many industries, particularly those focused on manufacturing and production. By understanding the complexities of supplier selection, supply chain management, sustainability considerations, and technological advancements, companies can develop effective procurement strategies. As the market for TiO2 continues to evolve, staying informed and adaptable will be essential for businesses aiming to maintain a competitive edge while ensuring the quality and sustainability of their products.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025