ธ.ค. . 03, 2024 17:59 Back to list

Lithopone Production Techniques and Leading Manufacturers in the Paint Industry

The Role of Lithopone in Paint Manufacturing

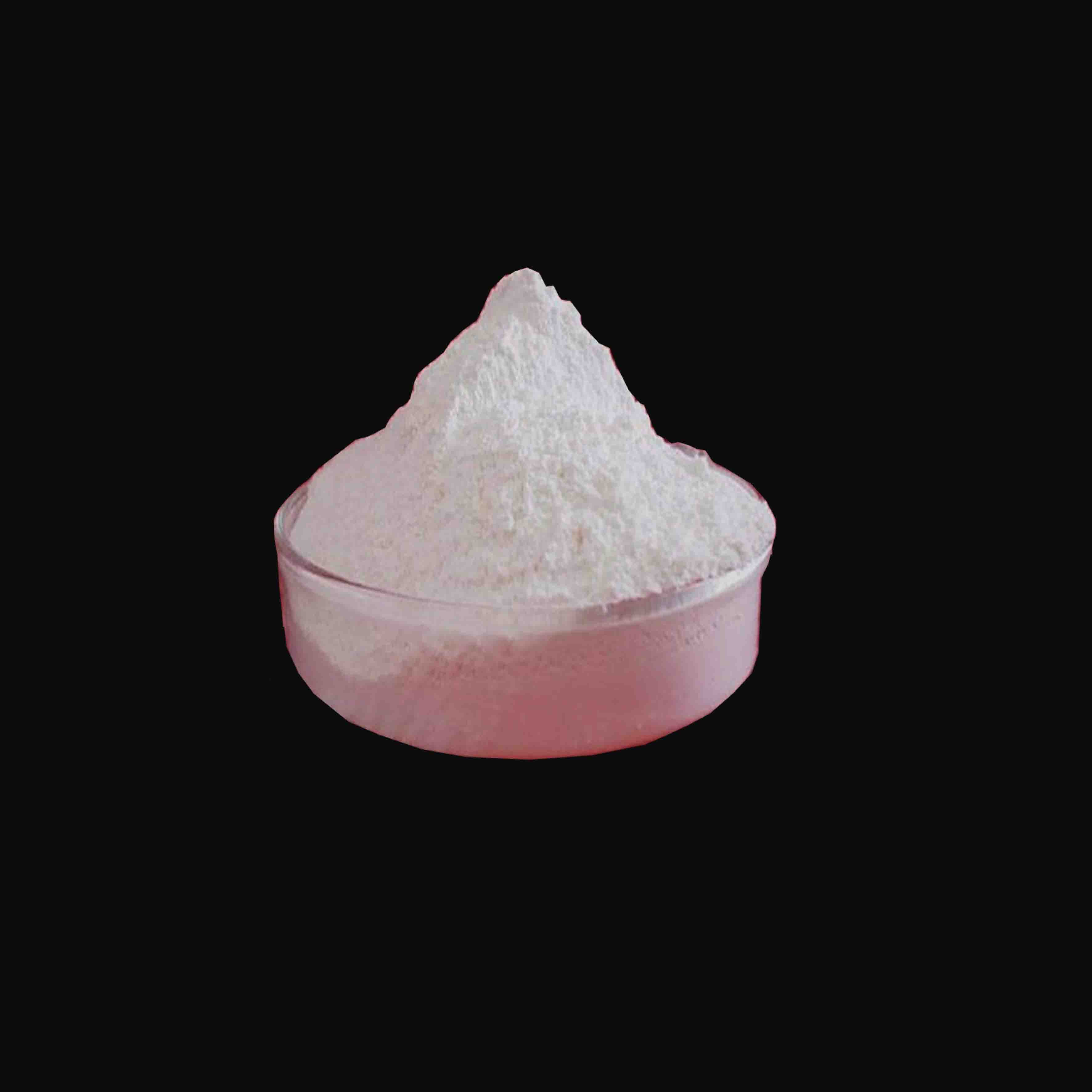

Lithopone, a white pigment composed of zinc sulfide and barium sulfate, has been a staple in the paint industry for decades. Renowned for its excellent opacity and durability, lithopone is used as a pigment in a wide array of products, from interior paints to industrial coatings. This article delves into the importance of lithopone, the manufacturing process, and the role of lithopone factories in the paint industry.

What is Lithopone?

Lithopone is a combination of two primary compounds zinc sulfide (ZnS) and barium sulfate (BaSO₄). Originally discovered in the 19th century, lithopone emerged as a superior alternative to traditional white pigments like lead white and zinc oxide. Its key attributes include high hiding power, low oil absorption, and resistance to discoloration, making it an ideal choice for manufacturers looking for reliable and stable white pigments.

Chemical Properties and Benefits

Lithopone presents several advantages when used in the manufacturing of paints. Its high refractive index contributes to the pigment's excellent opacity, allowing it to effectively cover underlying surfaces. Additionally, lithopone demonstrates exceptional resistance to UV light, preventing fading over time. This characteristic is particularly crucial for outdoor applications where prolonged sunlight exposure can degrade other paint formulations.

Moreover, lithopone is considered environmentally friendly relative to older pigments that contain toxic materials like lead. As regulations continue to tighten around hazardous substances in consumer products, manufacturers are increasingly turning to safer alternatives like lithopone.

The Manufacturing Process

Lithopone production typically involves the precipitation of zinc sulfide and barium sulfate. The manufacture of lithopone can be broken down into several key steps

1. Raw Material Preparation The primary raw materials—zinc oxide and barium sulfate—are sourced and pre-processed to create a suitable feed for the reaction.

paint lithopone factories

2. Precipitation Reaction The reaction occurs in an aqueous solution where zinc oxide reacts with hydrogen sulfide, leading to the formation of zinc sulfide. Concurrently, barium sulfate is introduced to the mixture.

3. Filtration and Washing Once the precipitation reaction is complete, the resultant products are filtered to remove excess liquid. The solid components are thoroughly washed to eliminate impurities.

4. Drying Process After washing, the lithopone is dried in a controlled environment to ensure no moisture remains, which could affect the pigment's quality.

5. Milling and Grinding The dried lithopone is then milled to achieve a fine powder suitable for incorporation into paint formulations.

6. Quality Control Finally, rigorous quality control measures are conducted to ensure the lithopone meets industry standards for consistency in color, particle size, and performance characteristics.

Lithopone Factories in the Paint Industry

Lithopone factories play an essential role in the supply chain of the paint industry. These facilities are strategically located near major raw material sources, allowing for cost-effective production and transportation. By leveraging advanced production techniques and stringent quality control procedures, lithopone factories can meet the rising demand for high-quality white pigments across various applications.

Furthermore, the evolution of lithopone production technology has enabled factories to produce tailored variants of the pigment. This customization allows paint manufacturers to better meet consumer needs and adapt their products to specific environmental conditions.

Conclusion

In summary, lithopone has established itself as a vital component in the paint manufacturing industry, offering unmatched benefits in terms of stability, opacity, and safety. As markets expand and consumer preferences shift towards eco-friendly products, the demand for lithopone and the factories producing it are likely to grow. By focusing on quality production and eco-conscious practices, lithopone factories are well-positioned to continue supporting the needs of the paint industry while contributing to a more sustainable future. Whether in architectural coatings or industrial applications, lithopone remains a key player in the quest for high-performing, long-lasting paints that meet modern standards.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025