ธ.ค. . 01, 2024 14:32 Back to list

Understanding Lithopone Production and Its Applications in Various Industries

The Manufacturing Process of Lithopone A Closer Look

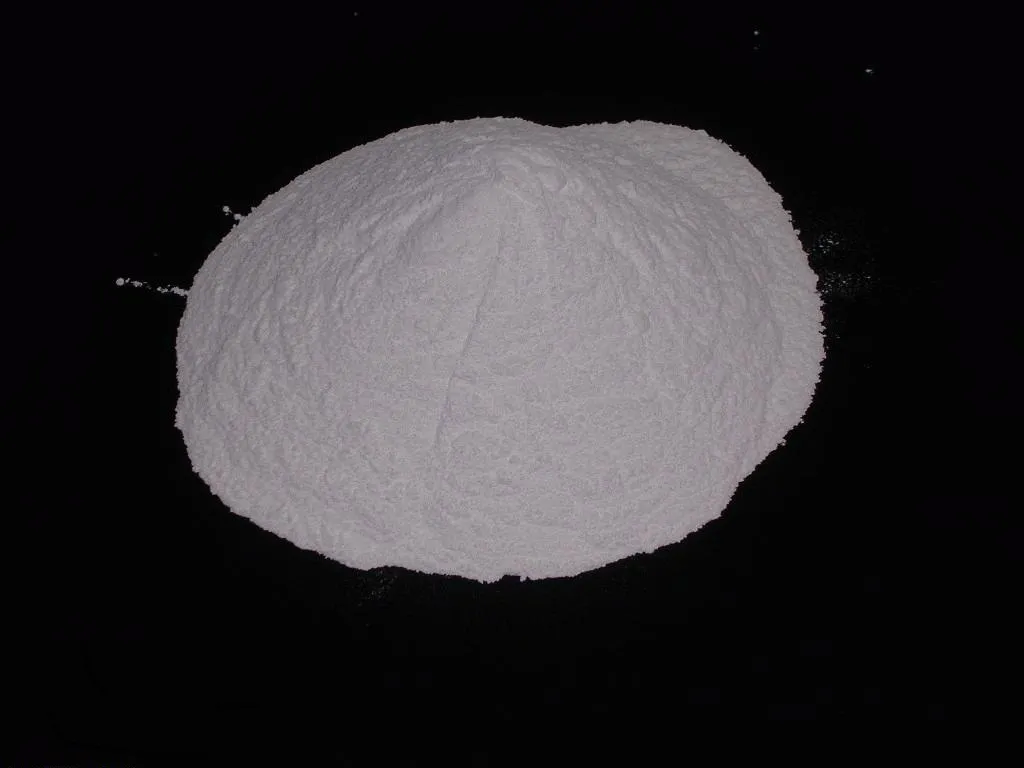

Lithopone is an important white pigment used in a variety of applications, including paints, coatings, plastics, and rubber. Known for its excellent opacity and durability, lithopone is a composite of zinc sulfide (ZnS) and barium sulfate (BaSO4). This compound offers several advantages over other white pigments, making it a popular choice among manufacturers. In this article, we will delve into the manufacturing process of lithopone and its significance in modern industries.

What is Lithopone?

Lithopone is a white pigment that appears as a fine powder and is commercially produced mainly in the form of a barium-zinc sulfide. It was first developed in the late 19th century as a cheaper alternative to titanium dioxide (TiO2), which is widely acknowledged as one of the best white pigments due to its high refractive index and brightness. However, lithopone presents some appealing features that make it suitable for specific applications. It is less expensive and provides good opacity and hiding power without the potential environmental risks associated with titanium dioxide.

The Manufacturing Process

The production of lithopone generally involves a two-step process, which includes precipitation and drying. Here’s an overview of each phase

1. Raw Material Preparation The primary raw materials required for lithopone production are zinc oxide (ZnO), barium sulfide (BaS), and sulfuric acid (H2SO4). The purity and quality of these raw materials are crucial, as they greatly influence the final product's properties.

2. Precipitation Reaction The manufacturing process begins with the reaction of zinc oxide with barium sulfide in a controlled environment. This reaction occurs in a solution where sulfuric acid is introduced to facilitate the formation of lithopone.

lithopone is factory

The basic chemical reaction can be represented as follows \[ \text{ZnO} + \text{BaS} + \text{H}_2\text{SO}_4 \rightarrow \text{ZnS} \cdot \text{BaSO}_4 \downarrow \] The formation of the precipitate (lithopone) is a critical phase. Manufacturers need to carefully control pH levels, temperature, and concentration to ensure uniform particle size and consistency.

3. Filtration and Washing Once the precipitation reaction is complete, the mixture is subjected to filtration to separate the lithopone from the liquid phase. The filter cake is then washed to remove any unreacted materials and impurities.

4. Drying and Milling After washing, the wet lithopone is dried in industrial drying equipment. Once dried, the material is milled to achieve the desired particle size. This milling process often involves using fine grinding technology to ensure a smooth and homogenous powder.

5. Quality Control and Packaging After milling, the lithopone undergoes rigorous quality control tests to ensure that it meets industry standards. Factors such as opacity, brightness, and particle size distribution are measured. Once the product passes all tests, it is packaged and dispatched for sale to various industries.

Applications of Lithopone

Lithopone's versatility makes it suitable for a wide range of applications. In the paint and coating industry, it is valued for its ability to enhance opacity and prevent yellowing. In plastics and rubber manufacturing, lithopone acts as a filler, improving durability and weather resistance. Additionally, its non-toxic nature makes it an appealing choice for environmentally conscious consumers.

Conclusion

Lithopone remains an essential component in numerous industries thanks to its cost-effectiveness and performance characteristics. Understanding the manufacturing process provides insight into how this important pigment is produced and highlights the technology and chemistry involved in its creation. As industries seek sustainable and economical options, lithopone continues to hold its ground as a reliable pigment choice.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025