Oct . 22, 2025 18:20 Back to list

Key Properties of Titanium Dioxide R5566

In the industrial materials sector, titanium dioxide r5566 and reliable tio2 suppliers are crucial for various manufacturing processes. As a wholesaler, having a comprehensive understanding of the key properties of titanium dioxide r5566 is essential to meet the diverse needs of industrial buyers. Tangshan Dachuan Machinery Co.,ltd. recognizes the significance of high - quality titanium dioxide and offers products that cater to a wide range of industrial applications.

Titanium Dioxide R5566 Specification Table

|

Aspect |

Details |

|

Classification |

Titanium Dioxide |

|

CAS No. |

13463 - 67 - 7 |

|

Model Number |

CR6618 |

|

MF |

TiO2 |

|

Place of Origin |

Hebei, China |

|

Grade Standard |

Industrial Grade |

|

Purity |

≥93.5% |

|

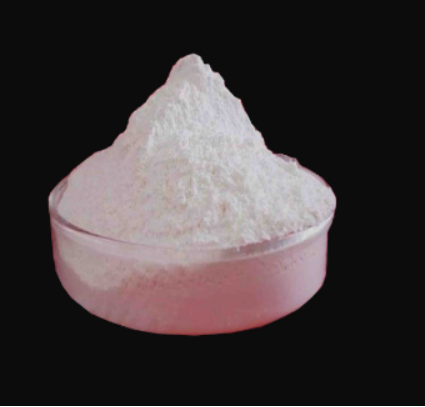

Appearance |

White |

|

Application |

Coating/Ink/Leather, color paste and sheet/Plastic |

|

Product name |

tio2 poudre |

|

Surface treated |

zirconium, aluminum |

|

Brightness, % |

≥97.00 |

|

Oil absorption, g/100g |

≤20 |

|

Tinting Strength, % |

≥105 |

|

Residue on sieve (45μm), % |

≤0.02 |

|

Resistivity, Ω.m |

≥60 |

|

Oil dispersibility, μm |

≤30 |

|

pH Value |

6.0 - 8.5 |

|

Volatile at 105℃ (m/m), % |

≤0.5 |

Applications in Coating Industry with Titanium Dioxide R5566

- In the coating industry, titanium dioxide r5566 plays a vital role. Its high brightness, with a value of ≥97.00%, ensures that coatings have a vivid and attractive appearance. This is particularly important for architectural coatings, where the visual appeal of painted surfaces is a key factor. The excellent tinting strength, ≥105%, allows for the creation of coatings with intense and consistent colors, meeting the diverse aesthetic requirements of customers. Whether it's for interior walls or exterior facades, titanium dioxide r5566 helps coatings achieve the desired color saturation and brightness.

- Moreover, the low oil absorption of ≤20 g/100g contributes to the formulation of coatings with good flow and leveling properties. Coatings made with titanium dioxide r5566 can be applied smoothly, resulting in a uniform and high - quality finish. Additionally, the good oil dispersibility, with a particle size of ≤30 μm, ensures that the titanium dioxide is evenly dispersed in the coating medium, preventing agglomeration and ensuring consistent performance throughout the coating film. This is essential for maintaining the durability and longevity of the coating, as uneven dispersion can lead to weak points and reduced resistance to environmental factors.

Role in Ink Production Using Titanium Dioxide R5566

- For ink production, titanium dioxide r5566 is an indispensable component. The high purity of ≥93.5% ensures that the ink has minimal impurities, which is crucial for maintaining the clarity and quality of printed materials. Impurities can cause issues such as poor color reproduction or clogging of printing equipment. The white appearance of the titanium dioxide provides a bright base for formulating various colored inks, allowing for accurate color matching and vibrant prints.

- The low residue on sieve (≤0.02% at 45μm) means that the particles are fine and uniform, which is beneficial for the printing process. Fine particles ensure that the ink flows smoothly through printing nozzles or plates, preventing blockages and ensuring consistent print quality. Additionally, the good resistivity (≥60 Ω.m) helps in maintaining the electrical properties of certain types of inks, such as those used in electronic printing applications, ensuring their proper functionality.

Utilization in Leather and Plastic Industries with Titanium Dioxide R5566

- In the leather industry, titanium dioxide r5566 is used to enhance the appearance and durability of leather products. Its high brightness gives leather a glossy and appealing finish, while the good tinting strength allows for the creation of various leather colors, from classic shades to vibrant hues. The surface treatment with zirconium and aluminum improves the compatibility of the titanium dioxide with leather processing chemicals, ensuring that it adheres well to the leather surface and does not easily fade or wear off. This contributes to the longevity of leather goods, making them more resistant to daily wear and tear.

- For the plastic industry, titanium dioxide r5566 is widely used to impart whiteness and opacity to plastic products. Whether it's for plastic packaging, consumer goods, or industrial components, the high brightness and tinting strength of the titanium dioxide ensure that the plastic products have a clean and attractive appearance. The low volatile content (≤0.5% at 105℃) is important as it prevents the release of volatile substances during the plastic processing, such as extrusion or injection molding, which could affect the quality of the final product or the processing equipment. Additionally, the good dispersibility in oils and other plastic processing media ensures that the titanium dioxide is evenly distributed throughout the plastic matrix, resulting in consistent color and properties across the entire product.

Titanium Dioxide R5566 FAQS

What key properties make titanium dioxide r5566 suitable for coating applications?

The unique properties of titanium dioxide r5566 render it highly suitable for coating applications. Its exceptional brightness of ≥97.00% imparts a striking and vivid look to coatings, making it a prime choice for architectural titanium dioxide r5566 - enhanced coatings where visual allure is key. The remarkable tinting strength of ≥105% enables the creation of coatings with rich, consistent colors, fulfilling the diverse aesthetic demands of customers. The low oil absorption of ≤20 g/100g aids in formulating coatings with excellent flow and leveling, while the good oil dispersibility with a particle size of ≤30 μm ensures that titanium dioxide r5566 disperses evenly in the coating medium, resulting in a uniform and durable finish.

How does titanium dioxide r5566 contribute to the performance of ink production?

Titanium dioxide r5566 is a linchpin in ink production. Its high purity of ≥93.5% guarantees that inks have minimal impurities, which is vital for maintaining the sharpness and clarity of printed materials. The white appearance of titanium dioxide r5566 provides an ideal base for formulating a wide spectrum of colored inks, enabling precise color matching and producing vibrant prints. The fine and uniform particles, indicated by the low residue on sieve (≤0.02% at 45μm), ensure seamless ink flow through printing equipment, preventing blockages and ensuring consistent print quality. Moreover, its good resistivity (≥60 Ω.m) plays a crucial role in maintaining the electrical properties of titanium dioxide r5566 - incorporated inks used in electronic printing, ensuring their proper functionality.

Why is surface treatment crucial for the performance of titanium dioxide r5566?

Surface treatment is of paramount importance for titanium dioxide r5566 as it significantly enhances its compatibility with other materials in various applications. When titanium dioxide r5566 is surface - treated with zirconium and aluminum, it demonstrates improved adhesion in the leather industry, enhancing the durability and wear - resistance of leather products. In the context of coatings and plastics, the surface treatment promotes better dispersion and interaction of titanium dioxide r5566 with the surrounding medium, ensuring enhanced overall performance and stability of the final products.

What support can tio2 suppliers like Tangshan Dachuan Machinery Co.,ltd. offer for the use of titanium dioxide r5566?

Tio2 suppliers such as Tangshan Dachuan Machinery Co.,ltd. offer comprehensive support to industrial buyers. They ensure a stable supply of high - quality products like titanium dioxide r5566, maintaining consistent product quality that helps manufacturers uphold the quality of their end products. These suppliers also provide valuable technical support, guiding buyers on the optimal utilization of titanium dioxide r5566 in different applications. With flexible ordering options and efficient logistics, tio2 suppliers assist industrial buyers in managing their inventory effectively, reducing the risk of production delays caused by material shortages.

How do other titanium dioxide models from Tangshan Dachuan Machinery Co.,ltd. complement titanium dioxide r5566?

Tangshan Dachuan Machinery Co.,ltd. offers a diverse range of titanium dioxide models in addition to titanium dioxide r5566. Models like CR930, CR960, CR980, and CA100 are available to meet different industrial requirements. Each model has unique characteristics, catering to specific needs in applications such as coatings, plastics, and more. Wholesalers can choose from this variety of models, including titanium dioxide r5566, to provide their customers with the most suitable products for their manufacturing processes. Different models can be selected based on specific requirements like varying levels of brightness, tinting strength, or dispersibility needs, ensuring a comprehensive solution for diverse industrial applications.

-

Application of Titanium Dioxide 2195 in Water Purification

NewsNov.14,2025

-

What are the global market trends of Titanox titanium dioxide in recent years

NewsNov.14,2025

-

Effect of particle size distribution on the optical properties of R996 TiO2

NewsNov.14,2025

-

Latest Technological Innovations in Rutile Titanium Dioxide Manufacturing

NewsNov.14,2025

-

Compatibility of Titanium Dioxide Concrete Pigment with Different Concrete Admixtures

NewsNov.14,2025

-

Environmental Impact of Titanium Dioxide Pigment Manufacturing and Mitigation Measures

NewsNov.14,2025