ก.ค. . 27, 2024 19:11 Back to list

Exploring the Role of Titanium Dioxide in Enhancing Paper Production and Quality

Titanium Dioxide in Paper Making Enhancing Quality and Sustainability

Titanium dioxide (TiO2) is a versatile and widely used white pigment in many industries, including paper manufacturing. Its unique properties make it an essential component in producing high-quality paper products. As the demand for eco-friendly and sustainable materials increases, the role of titanium dioxide in paper making is becoming even more significant. This article will explore how TiO2 enhances the quality of paper and contributes to sustainability in the industry.

The Role of Titanium Dioxide

In the paper-making process, titanium dioxide is primarily used as a filler and a coating pigment. Its high refractive index ensures that it effectively scatters light, which imparts a bright white color to the paper. This brightness is crucial for various applications, including printing papers, writing papers, and specialty papers. TiO2 allows manufacturers to produce bright, high-quality paper that meets the stringent requirements of modern consumers.

Another benefit of titanium dioxide is its non-toxic nature and high stability. Unlike some traditional pigments that may contain harmful substances, TiO2 is safe for both human health and the environment. This characteristic makes it an attractive alternative for manufacturers looking to enhance their product offerings without compromising safety and sustainability.

Enhancing Paper Properties

Using titanium dioxide in paper making not only improves the aesthetic qualities but also enhances physical properties. TiO2 contributes to the paper's opacity, allowing for better print quality and reducing show-through from the other side of the sheet. This is particularly important for high-quality printing applications where clarity and color vibrancy are paramount.

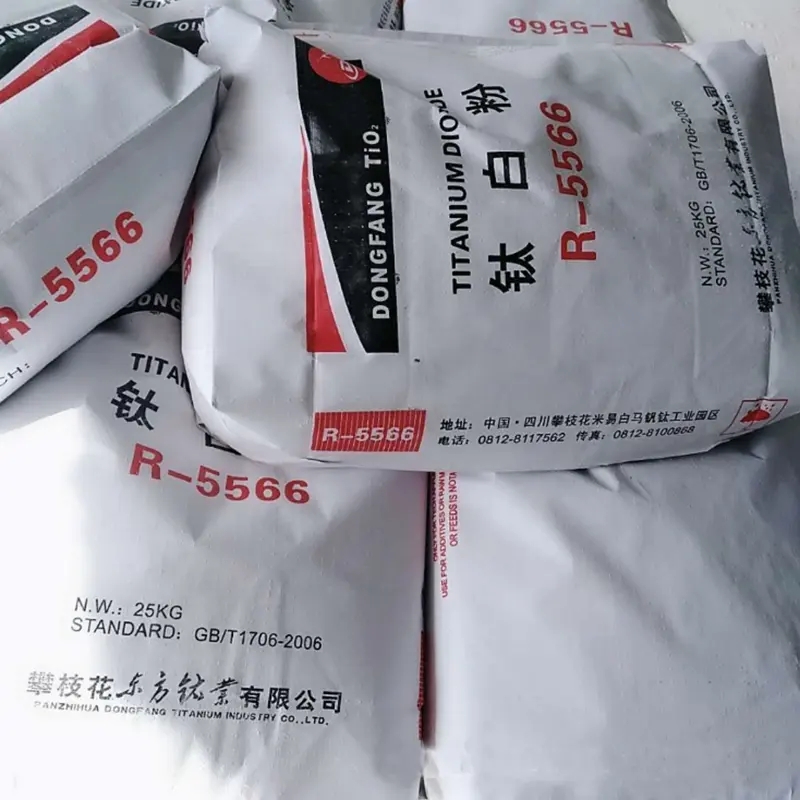

titanium dioxide for paper making

Additionally, TiO2 can positively influence the paper's surface characteristics. Papers coated with titanium dioxide exhibit improved smoothness, glossiness, and printability, making them ideal for high-end publishing and packaging materials. The incorporation of TiO2 can also enhance the durability of paper products, making them more resistant to tearing and wear.

Environmental Sustainability

As the paper industry faces increasing scrutiny over its environmental practices, titanium dioxide emerges as a key player in promoting sustainability. The use of TiO2 in paper production can reduce the need for bleaching agents and other harmful chemicals, leading to a lower environmental impact. Furthermore, TiO2 is often derived from abundant and naturally occurring mineral sources, making it a more sustainable choice compared to synthetic alternatives.

Moreover, the ongoing development of biodegradable and recyclable paper products has led to innovative uses of titanium dioxide. Researchers are exploring ways to incorporate TiO2 into biodegradable paper composites, which can further reduce environmental concerns associated with traditional paper products. The use of TiO2 in such materials could pave the way for a new generation of sustainable paper offerings that meet consumer demand for eco-friendly options.

Conclusion

Titanium dioxide plays a vital role in modern paper making, contributing to enhanced product quality and sustainability. Its ability to improve brightness, opacity, and physical properties while remaining non-toxic makes it a preferred choice among paper manufacturers. With the industry's shift towards more sustainable practices, the demand for TiO2 is likely to grow, driving innovation and research into its applications.

As consumers become more conscious of the environmental impact of their purchases, the paper industry must adapt by developing products that align with sustainability goals. The ongoing integration of titanium dioxide into paper-making processes represents a crucial step toward achieving this objective, ensuring that the industry can meet the challenges of the future while maintaining high quality and performance standards.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025