Sep . 30, 2025 10:05 Back to list

13463-67-7 titanium dioxide using for coating supplier OEM?

Rutile TiO2 for Modern Coatings: Field Notes, Specs, and Real-World Use

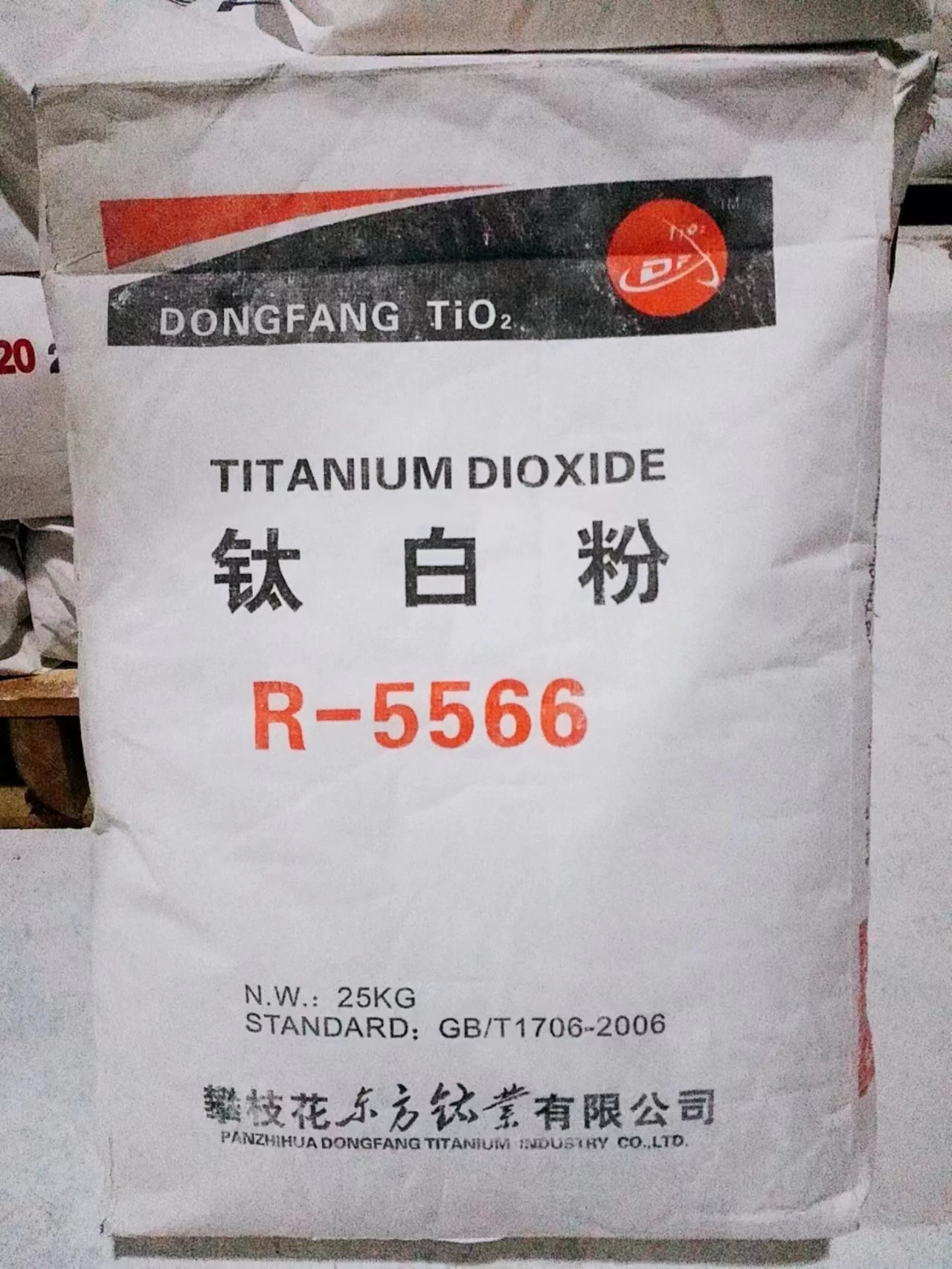

If you’ve been hunting for an honest, lab-tested white pigment that doesn’t blink in harsh weather, this is for you. I’ve been following the rutile-grade market closely, and the product many buyers keep asking about is 13463-67-7 titanium dioxide using for coating supplier. It’s sold as “wholesale dio2 cas 13463-67-7,” an industrial-grade pigment (R-5566) coming out of Jindi Industrial Park, Dacheng County, Langfang City, Hebei Province. To be honest, the consistency batch-to-batch has been the standout.

Industry snapshot: why R-5566 keeps trending

Architectural coatings are pushing low-VOC waterborne systems, auto refinishers want higher DOI and UV holdout, and marine/industrial lines demand hiding power without chalking. Rutile TiO2 with robust alumina/silica surface treatment hits that sweet spot—opacity, brightness, and weathering. Actually, the quieter story is dispersion efficiency, which saves grind time and energy costs. Many customers say that’s where the ROI lives.

Product overview and origin

Product: Industrial Grade Pigment White Powder Dioxide Titanium R-5566. Origin: Jindi Industrial Park, Dacheng County, Langfang City, Hebei Province. In practice, it lands well in both waterborne and solventborne coatings, including high-solids and 2K polyurethane systems. I guess the blue undertone also helps clean up warm tint bases.

Technical specifications (typical)

| Crystal form | Rutile (surface-treated Al2O3/SiO2) |

| TiO2 content | ≥ 93% (≈ real-world) |

| Brightness (L) | ≈ 98 |

| Tinting strength (relative) | ≥ 1850 |

| Oil absorption | ≈ 17 g/100 g |

| pH (aqueous slurry) | 6.5–8.5 |

| Volatiles at 105°C | ≤ 0.5% |

| 45 μm residue | ≤ 0.02% |

| Specific gravity | ≈ 4.1 g/cm³ |

Data are typical; real-world use may vary by mill base, resin, and dispersion equipment.

Process flow (condensed)

High-grade ilmenite feedstock → chlorination to TiCl4 → oxidation to TiO2 → micronizing and classification → alumina/silica surface treatment → drying → quality control (ISO/ASTM methods) → packaging (25 kg bags or FIBC).

Applications and service life

- Architectural exterior paints (acrylic, silicone-modified): service life ≈ 8–12 years with proper film build.

- Automotive refinish clear/solid colors: high DOI, low yellowing under UV bake.

- Industrial primers and topcoats: improved hiding, salt-spray resistance when paired with anticorrosives.

- Marine and OEM equipment coatings: robust weathering and chalk resistance.

Testing, compliance, and certifications

- Classification: per ISO 591-1 (Rutile for coatings) and ASTM D476.

- Opacity: ISO 6504-3 hiding power; Gloss: ISO 2813.

- Color metrics: ISO 7724/ASTM E308; Particle size: ISO 13320.

- Weathering: ASTM G154 QUV; Corrosion systems: ISO 9227 (salt spray, system-dependent).

- Management systems often include ISO 9001, ISO 14001; REACH registration available, per supplier docs.

Vendor comparison (snap view)

| Vendor | Grade/Route | Weathering | Tint strength | Lead time | Certs |

|---|---|---|---|---|---|

| CQ TiO2 (R-5566) | Rutile, chloride | High | High | ≈ 10–15 days | ISO 9001/14001, REACH |

| Vendor A | Rutile, sulfate | Medium–High | Medium | ≈ 3–4 weeks | ISO 9001 |

| Vendor B | Anatase | Medium | Medium | ≈ 2–3 weeks | Basic QC |

Customization and logistics

- Surface treatment tuning for waterborne vs. solventborne vs. UV-cure systems.

- Dispersant compatibility mapping upon request; grind curves supplied.

- Packaging: 25 kg paper bags or ≈ 1,000 kg FIBC; palletization per export norms.

Case notes from the field

- Auto refinish plant cut grind time by ≈ 12% after switching, with +2–3 GU at 60° gloss.

- Exterior acrylic facade paint boosted contrast ratio from 0.96 to 0.98 at equal PVC—small number, big visual gain.

- Marine primer line reported steadier color after 500 h QUV (ΔE ≈ 0.8 vs. 1.4 prior grade).

If you’re shortlisting pigments, keep an eye on 13463-67-7 titanium dioxide using for coating supplier consistency in dispersion and hiding at target PVC—those two usually make or break a launch. And yes, samples help; production mills tell the truth.

Authoritative citations

- ISO 591-1: Titanium dioxide pigments—Specifications and methods of test.

- ASTM D476: Standard Classification for Titanium Dioxide Pigments.

- ISO 6504-3: Paints and varnishes—Determination of hiding power.

- ISO 2813: Paints and varnishes—Determination of gloss value.

- ASTM G154: Operating fluorescent UV lamp apparatus for exposure of nonmetallic materials.

- ISO 13320: Particle size analysis—Laser diffraction methods.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025