செப் . 22, 2024 23:36 Back to list

titanium dioxide application range factory

Titanium Dioxide Application Range in Factories

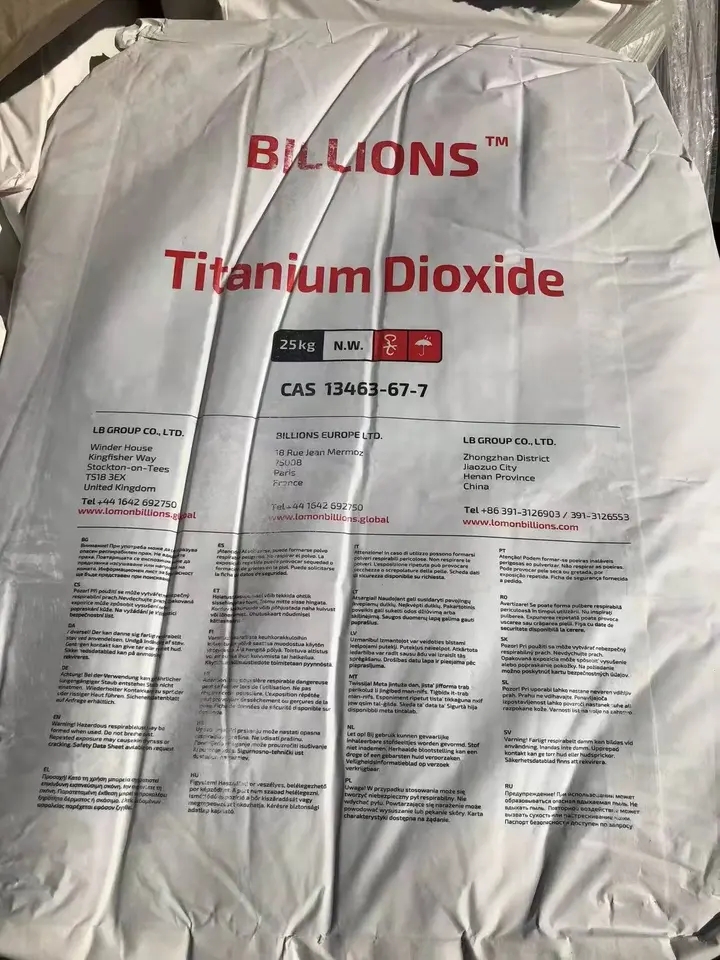

Titanium dioxide (TiO2) is a versatile and widely used inorganic compound, known for its exceptional brightness and high refractive index. Its applications span various industries, making it an essential component in numerous products that we use daily. In factory settings, titanium dioxide is primarily utilized in the manufacture of paints, coatings, plastics, paper, and a variety of other materials. This article delves into the diverse applications of titanium dioxide in manufacturing and highlights its significance in enhancing product quality and performance.

One of the most significant applications of titanium dioxide is in the painting and coatings industry. TiO2 is the key pigment used for producing high-opacity white paints and coatings, which provide excellent coverage and brightness. Its ability to reflect light enhances the durability and aesthetic appeal of coated surfaces. Whether it's for residential, commercial, or industrial applications, titanium dioxide ensures that paints retain their color and luster over time, resisting fading and degradation.

In the plastics industry, titanium dioxide serves multiple purposes. It is used as a pigment to improve the whiteness and opacity of plastic products such as containers, packaging materials, and automotive parts. The incorporation of TiO2 not only enhances the visual appeal of plastic items but also improves their durability by providing UV stabilization. This characteristic is particularly important for products exposed to sunlight, as it helps to prevent discoloration and material degradation.

titanium dioxide application range factory

In the paper industry, titanium dioxide is employed to enhance the brightness and opacity of paper products. The inclusion of TiO2 in paper pulp contributes to a smoother and glossier finish, making it suitable for high-quality printing applications. Its use in paper manufacturing ensures that important printed materials, such as magazines and promotional brochures, maintain visual clarity and attractiveness over time.

Beyond these primary industries, titanium dioxide is also significant in the production of ceramics, textiles, and personal care products. In ceramics, TiO2 is used as a glaze additive, providing a bright, reflective surface that enhances the aesthetic qualities of pottery and tiles. In textiles, titanium dioxide is applied as a dyeing agent, offering benefits such as color robustness and protection against UV radiation. Additionally, in personal care products like sunscreens, titanium dioxide plays a crucial role as a physical sunscreen agent that helps protect the skin from harmful UV rays.

Emerging applications of titanium dioxide are also gaining momentum, particularly in the realm of photocatalysis. Research is exploring its use in air and water purification systems, where TiO2 can help break down pollutants in the presence of light, leading to cleaner environments. This ability positions titanium dioxide as a promising candidate for sustainable manufacturing practices and environmentally friendly technologies.

In conclusion, titanium dioxide's extensive application range in factories reflects its critical role in enhancing product quality across various industries. From providing exceptional whiteness and opacity in paints and plastics to improving the performance of paper and personal care products, TiO2 remains an indispensable chemical in modern manufacturing. As industries strive for innovation and sustainability, the importance of titanium dioxide will only continue to grow, ensuring its relevance in an evolving marketplace.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025