ஜூலை . 22, 2024 00:55 Back to list

Titanium Dioxide Suppliers for High-Quality Colorants and Sustainable Pigment Solutions in Various Industries

The Role of Titanium Dioxide Suppliers in the Colorant Industry

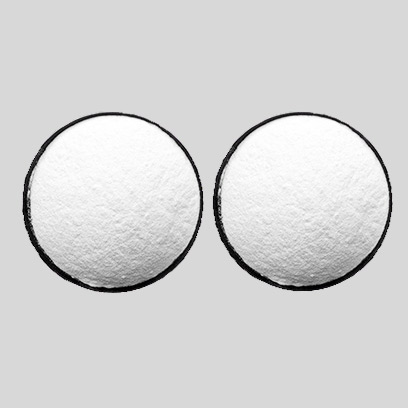

Titanium dioxide (TiO2) is one of the most widely used colorants in the world, renowned for its exceptional whiteness, brightness, and opacity. Its applications range from paints and coatings to plastics and cosmetics. As industries increasingly seek high-quality and sustainable materials, the role of titanium dioxide suppliers has become crucial. This article explores the importance of these suppliers in the colorant industry, the characteristics of titanium dioxide, and the evolving landscape of demand and supply.

Characteristics and Applications of Titanium Dioxide

Titanium dioxide is a white, opaque pigment derived from titanium ore. Its unique properties include high refractive index, durability, and resistance to discoloration under UV light, making it an ideal pigment for various applications. In paints and coatings, TiO2 enhances coverage, durability, and color retention, which is essential for both aesthetic appeal and product performance. In the plastics industry, it acts as a UV stabilizer and improves the overall quality of the final product.

In addition to its traditional applications, titanium dioxide is also gaining traction in cosmetics, where it is valued for its safety and effectiveness as a pigment and UV filter

. The growing trend towards natural and mineral-based products has increased the demand for TiO2 in personal care products, further solidifying its position in the colorant market.The Supply Chain Dynamics of Titanium Dioxide

The supply chain for titanium dioxide involves several key players, ranging from mining companies that extract titanium ore to manufacturers that process it into pigment form. Titanium dioxide suppliers play a vital role in this chain by ensuring the availability, quality, and affordability of the product. They must navigate the complexities of sourcing raw materials, adhering to environmental regulations, and fulfilling the diverse needs of their customers.

colorant titanium dioxide suppliers

With the increased focus on sustainability, suppliers are also exploring innovations in the production process. For instance, many are implementing environmentally friendly practices to reduce the carbon footprint associated with TiO2 production. This includes the development of low-impact extraction methods and recycling initiatives that aim to reduce waste and promote resource efficiency.

Challenges Facing Titanium Dioxide Suppliers

Despite the robust demand for titanium dioxide, suppliers face several challenges that impact their operations. Fluctuations in raw material prices can significantly affect production costs, leading to potential price volatility in the market. Additionally, stringent environmental regulations in many countries require suppliers to invest in cleaner technologies, which can be both time-consuming and expensive.

Furthermore, the increasing competition in the global market necessitates that suppliers differentiate themselves through quality, customer service, and sustainability initiatives. As consumers and businesses become more informed and concerned about the environmental impact of their purchases, suppliers must adapt to these changing preferences by prioritizing sustainable practices.

The Future of Titanium Dioxide Supply

Looking ahead, the future of titanium dioxide suppliers appears promising. The global push for sustainability and environmentally friendly products is likely to drive innovations in TiO2 production and usage. Moreover, the continued growth in key end-use industries, such as construction, automotive, and personal care, indicates a robust and expanding market for titanium dioxide.

In conclusion, titanium dioxide suppliers play an indispensable role in the colorant industry by providing high-quality, sustainable products that meet diverse consumer and industrial needs. As the market continues to evolve, those suppliers who embrace innovation, sustainability, and adaptability will be best positioned to thrive in the competitive landscape. The commitment to quality and sustainability not only enhances their reputation but also contributes positively to the industry as a whole.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025