டிசம்பர் . 09, 2024 18:28 Back to list

Production of Anatase Titanium Dioxide TiO2 in Leading Manufacturing Facilities Worldwide

The Significance of Anatase Titanium Dioxide (TiO2) Factories

Anatase titanium dioxide (TiO2) is a vital compound utilized extensively across a variety of industries, including paint, coatings, plastics, cosmetics, and even the production of solar cells. The unique properties of anatase TiO2, such as its high refractive index, excellent UV resistance, and photocatalytic ability, make it an indispensable ingredient for many applications. This article explores the importance of anatase TiO2 factories, the manufacturing processes involved, and the challenges faced by this sector.

Understanding Anatase Titanium Dioxide

Titanium dioxide exists in several crystalline forms, with anatase and rutile being the most prominent. While rutile is more commonly used in applications that require higher durability and opacity, anatase is preferred for specific uses due to its superior photocatalytic properties. This means that anatase TiO2 can effectively break down organic pollutants and withstand UV radiation, making it ideal for surfaces that require self-cleaning or anti-fogging properties.

The Role of Factories in Production

Factories specializing in the production of anatase TiO2 are crucial for meeting the growing demand in various sectors. The manufacturing process typically involves several key steps

1. Raw Material Sourcing The primary raw material for TiO2 production is ilmenite, which contains iron and titanium. Other sources may include rutile and titania slag.

2. Chemical Processing The extracted material undergoes chemical processing to separate titanium from iron. This is commonly done using the sulfate or chloride process. The sulfate process involves digesting ilmenite in sulfuric acid, while the chloride process uses chlorine gas to produce titanium tetrachloride, which is then oxidized to form TiO2.

3. Crystallization and Calcination The titanium dioxide is then crystallized into its anatase form and calcined–a process where it is heated to high temperatures to achieve the desired crystalline structure and purity.

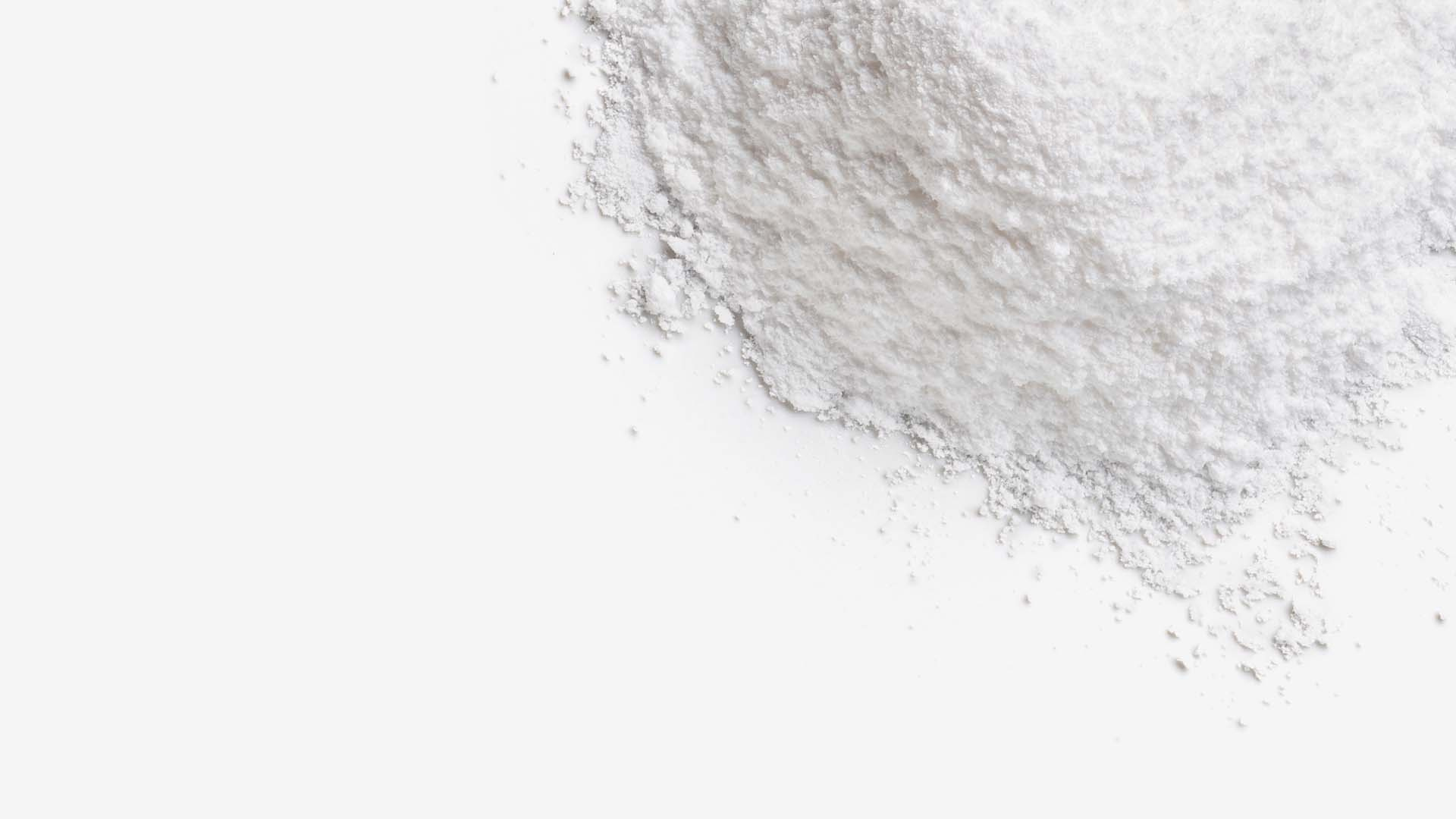

4. Finishing and Packaging The final products are often treated with surface modifications to enhance their properties, followed by milling into a fine powder, ready for packaging and distribution.

anatase titanium dioxide(tio2) factories

Economic Impact and Global Market

Anatase TiO2 factories play a significant economic role, particularly in regions rich in titanium ore. The market for TiO2 has been steadily growing, driven by increasing demand in construction, automotive, and the renewable energy sectors. According to industry reports, the global titanium dioxide market was valued at several billion dollars in recent years and is projected to continue expanding, which presents lucrative opportunities for manufacturers.

Countries such as China, the United States, and Germany are among the largest producers of anatase TiO2, benefiting from advanced technology and infrastructure. As these factories strive to improve production efficiency and reduce costs, they are also investing in research and development to create more sustainable manufacturing processes, thus improving their environmental footprint.

Challenges Faced by the Industry

Despite its growth potential, the anatase TiO2 industry faces several challenges. One significant concern is environmental regulation. The production processes can lead to the release of pollutants, making compliance with environmental standards a critical issue for manufacturers. Stricter regulations can increase operational costs and necessitate investments in cleaner technologies.

Additionally, fluctuations in raw material prices can impact production costs. The global supply chain is often affected by geopolitical tensions, trade disputes, and economic downturns, leading to uncertainties for manufacturers.

The industry is also experiencing a shift towards alternative materials and technologies. For instance, innovations in nanotechnology and the development of non-TiO2-based photocatalysts present potential competition. Factories must remain agile and adapt to these trends to maintain their market share.

Conclusion

Anatase titanium dioxide factories are integral to the global economy, providing essential materials for a wide range of applications. As the market for TiO2 continues to grow, these factories must navigate various challenges while embracing innovation and sustainability. By focusing on efficiency and environmental stewardship, the anatase TiO2 industry can not only thrive but also contribute to a more sustainable future in manufacturing and beyond.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025