டிசம்பர் . 15, 2024 04:54 Back to list

1250 mesh factories

The Significance of 1250 Mesh Factories in Modern Industry

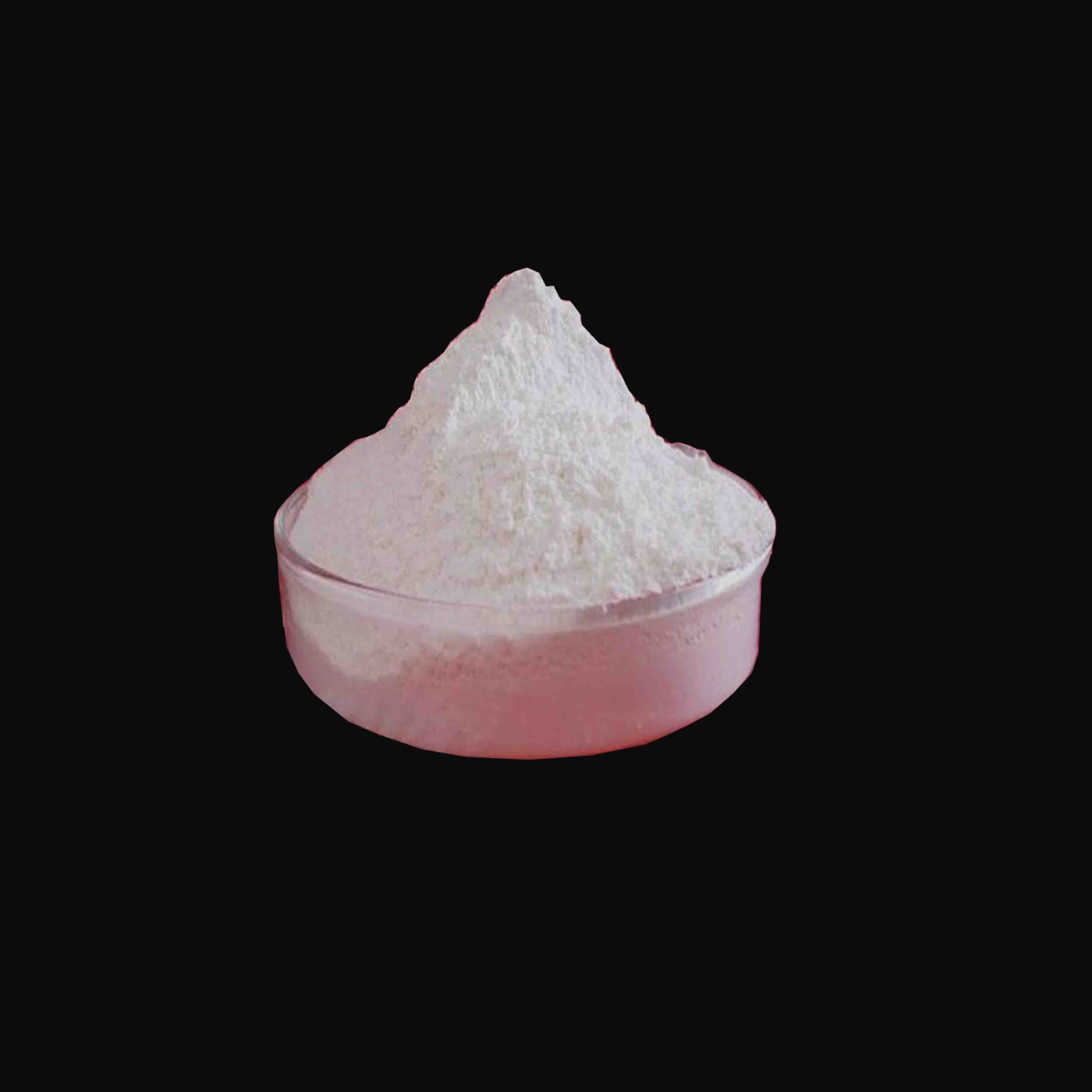

In today's fast-paced industrial landscape, the demand for fine materials has skyrocketed. Among these, 1250 mesh products play a pivotal role across various sectors including pharmaceuticals, cosmetics, food production, and advanced manufacturing. The term mesh refers to the size of the particles in a material, with 1250 mesh indicating incredibly fine particles that are filtered to a size of approximately 10 micrometers or smaller. The significance of 1250 mesh factories lies not only in their production capabilities but also in the broad spectrum of applications they serve.

One of the primary industries benefiting from the production of 1250 mesh materials is the pharmaceutical industry. In this field, the particle size of active ingredients can significantly affect the bioavailability of drugs. Finer particles often dissolve quicker and can be absorbed more efficiently by the body, making them crucial for effective formulations. As such, factories specializing in 1250 mesh products utilize advanced milling and grinding techniques to create powders that meet stringent regulatory standards. These techniques ensure that the final product not only achieves the desired particle size but also maintains the integrity and efficacy of the active ingredients.

Another significant area of application for 1250 mesh materials is in the cosmetic industry. Finely milled powders are essential for high-quality cosmetics, such as foundations and face powders that offer smooth application and a flawless finish. The ultrafine texture of 1250 mesh formulations allows for better blending with skin, creating a more natural look while minimizing the appearance of imperfections. Additionally, these fine particles can enhance the performance of cosmetic products by improving their longevity and resistance to wear.

1250 mesh factories

In the realm of food production, the importance of fine particles cannot be overstated. Finer ingredients, such as powdered sugar or spices, not only enhance the aesthetics of food products but also improve texture and flavor distribution. For example, a 1250 mesh flour can result in lighter baked goods with a superior texture, meeting the demands of both artisanal bakers and large-scale food manufacturers. Moreover, the food industry often requires strict adherence to safety and quality standards, and factories producing 1250 mesh materials must navigate these regulations to ensure consumer safety.

Advanced manufacturing processes also see a rising demand for 1250 mesh materials. Industries engaging in additive manufacturing or 3D printing often require ultra-fine powders to create intricate designs and complex components. The precision that 1250 mesh materials can offer is critical for ensuring optimal performance and functionality in engineered products.

However, operating a 1250 mesh factory comes with its challenges. The equipment and technology necessary for producing such fine materials can be costly and requires expert knowledge to manage. Additionally, the factories must implement effective quality control measures to ensure that the end products consistently meet industry specifications.

In conclusion, 1250 mesh factories are integral to modern industry, providing fine materials that enhance product performance across various sectors. Their role in pharmaceuticals, cosmetics, food production, and advanced manufacturing underscores their versatility and importance. As industries continue to evolve and demand increases for high-quality, finely milled materials, 1250 mesh factories will undoubtedly remain at the forefront of innovation and quality assurance, shaping the future of production and manufacturing processes.

-

High-Quality Determination of Sulphate as TiO2 Wholesale Supplier & Manufacturer from China

NewsJul.05,2025

-

Competitive Harga Titanium Dioxide Wholesale Prices from Leading Manufacturers in China

NewsJul.05,2025

-

High-Quality Titanium Dioxide R605 Powder Coating Multi-Purpose Product – Reliable China Supplier

NewsJul.04,2025

-

High Purity Chlorination Process Titanium Dioxide Manufacturer & Wholesale Supply from China

NewsJul.04,2025

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025