Desemba . 05, 2024 15:19 Back to list

use of tio2 factories

The Use of TiO2 Factories Applications and Environmental Considerations

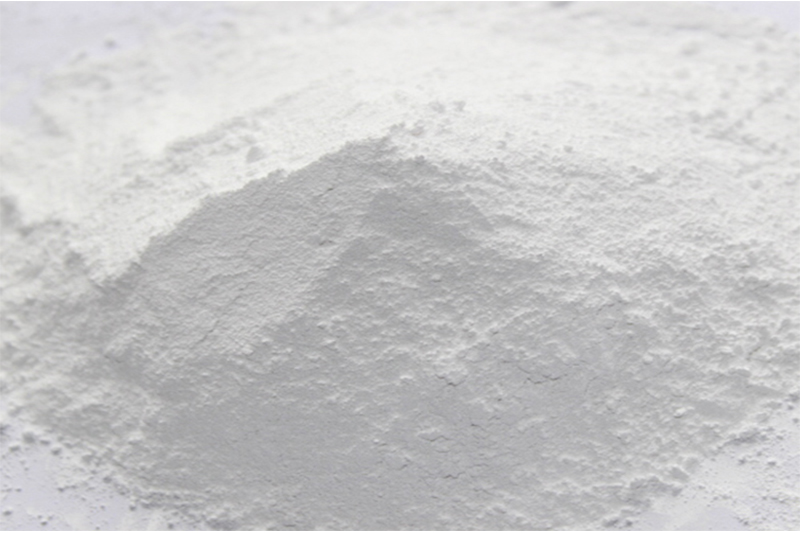

Titanium dioxide (TiO2) is a widely used compound with a variety of applications across different industries. Its unique properties, such as high refractive index, UV resistance, and opacity, make it a popular choice in many products. The significance of TiO2 factories, therefore, cannot be overstated as they play a crucial role in producing this essential compound. This article will explore the various applications of TiO2 while also considering the environmental impacts associated with its production.

Applications of TiO2

1. Paints and Coatings One of the primary applications of TiO2 is in the manufacture of paints and coatings. TiO2 serves as a white pigment that provides excellent coverage, brightness, and durability. Its ability to scatter light makes it an ideal choice for both indoor and outdoor applications. The construction and automotive industries heavily depend on TiO2 for creating weather-resistant finishes that maintain their aesthetic appeal over time.

2. Plastics TiO2 is also widely used in the plastics industry. It is added to plastics to enhance their opacity and brightness, making them more visually appealing. Furthermore, TiO2 can improve the UV resistance of plastics, which is especially important for products that will be exposed to sunlight, such as outdoor furniture and automotive components.

3. Cosmetics In the cosmetic industry, TiO2 is valued for its ability to reflect UV light, making it a useful ingredient in sunscreens and other skincare products. Its non-toxic nature allows it to be safely applied to the skin, providing protection against harmful UV rays without causing irritation. Additionally, TiO2 is used as a whitening agent in makeup products and skincare formulations.

4. Food Industry TiO2 is sometimes used as a food additive to enhance the whiteness and opacity of products such as dairy products and confections. While its use in food has raised questions about safety and regulatory standards, it remains popular in certain applications.

5. Pharmaceuticals In the pharmaceutical industry, TiO2 serves as an excipient in tablet formulations, providing a white color and acting as a lubricant. Additionally, it is used in the production of coatings for sustained-release medications, ensuring that drugs are delivered effectively to the body.

use of tio2 factories

Environmental Considerations

Despite its numerous applications, the production of TiO2 poses several environmental challenges that must be addressed. The manufacturing process typically involves the use of hazardous chemicals and generates waste products that can be harmful to the environment.

1. Chemical Pollution The production of TiO2 can involve processes such as the sulfate and chloride routes, both of which can release harmful byproducts into the environment. The sulfate process, for instance, generates sulfuric acid as a waste product, whereas the chloride process produces chlorine gas. Proper management and treatment of these byproducts are essential to minimize their impact on the environment.

2. Resource Consumption The extraction of titanium ore, from which TiO2 is derived, requires significant natural resources and energy input. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. Sustainable mining practices are essential to reduce the ecological footprint of TiO2 production.

3. Air Quality TiO2 factories can contribute to air pollution, as the emissions from production processes can release particulates and volatile organic compounds (VOCs) into the atmosphere. Regulating emissions and implementing advanced filtration systems can help mitigate these effects, but ongoing monitoring is necessary.

4. Recycling and Waste Management As industries continue to utilize TiO2 in various applications, questions surrounding recycling and waste management become increasingly important. Many products containing TiO2 can end up in landfills, contributing to a cycle of waste. Research into recycling methods and the development of biodegradable alternatives are critical for reducing the environmental impact of TiO2 use.

Conclusion

TiO2 factories are integral to a wide range of industries, providing essential materials that enhance products from paints to pharmaceuticals. However, the environmental implications of TiO2 production cannot be ignored. As industries continue to rely on this versatile compound, it is imperative that manufacturers implement sustainable practices to minimize their environmental footprint. By emphasizing responsible production, resource management, and the development of eco-friendly alternatives, the benefits of TiO2 can be enjoyed without compromising the health of our planet.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025