Novemba . 05, 2024 16:53 Back to list

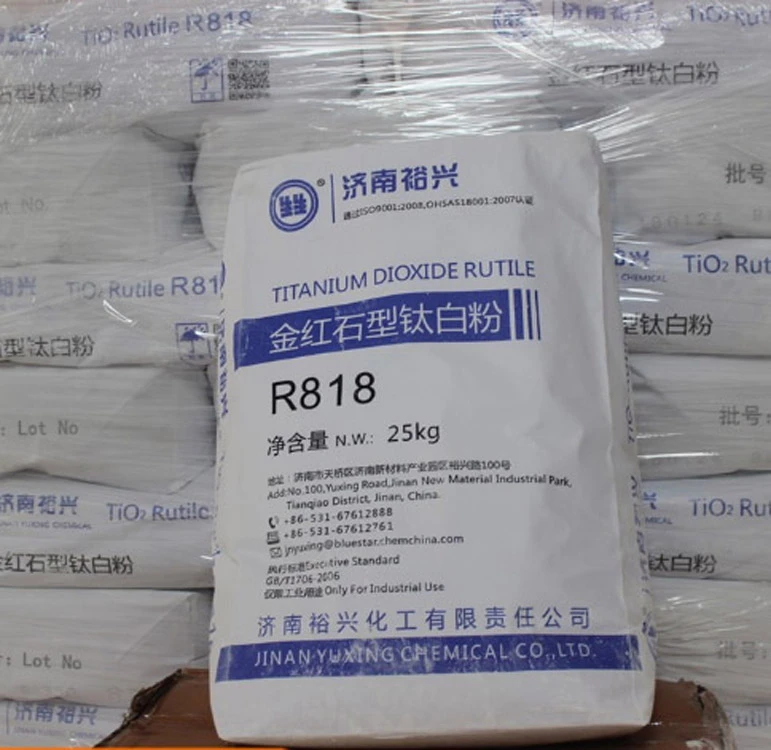

titanium dioxide rutile supplier

The Role of Titanium Dioxide Rutile Suppliers in Various Industries

Titanium dioxide (TiO₂) is a widely used compound that plays a critical role in various industries, thanks to its excellent properties, such as brightness, UV resistance, and stability. Among its two primary crystalline forms, rutile stands out due to its superior performance in many applications. The demand for titanium dioxide rutile has surged in recent years, leading to a burgeoning industry of suppliers. This article delves into the significance of titanium dioxide rutile suppliers, their impact on industries, and the future of this vital material.

Understanding Titanium Dioxide Rutile

Titanium dioxide exists in three main forms anatase, rutile, and brookite. Rutile titanium dioxide is characterized by its high refractive index and strong pigmenting properties. Because of these qualities, it is predominantly used as a white pigment in paints, coatings, plastics, paper, and cosmetics. Rutile TiO₂ is also employed in various applications such as the production of titanium metal, photocatalysis, and solar cells.

The production of titanium dioxide, particularly in its rutile form, is complex. It typically involves two processes the sulfate process and the chloride process, with the latter being the more prevalent method in recent years. As demand continues to rise, the role of suppliers who can provide high-quality rutile TiO₂ becomes increasingly important.

The Importance of High-Quality Suppliers

The quality of titanium dioxide rutile is paramount for its application in various industries. The suppliers must adhere to stringent quality control measures to ensure the product meets the necessary specifications. High-quality rutile TiO₂ is characterized by its purity, particle size, and dispersion properties. Discrepancies in quality can lead to significant issues, impacting the end products' performance and durability.

Suppliers specialize in sourcing titanium dioxide from reliable manufacturers and ensuring that the product meets international standards. This is particularly crucial for industries such as automotive and food packaging, where product safety and compliance with regulations are essential. The ability of suppliers to provide consistent quality and timely delivery directly affects the operations and efficiency of companies relying on TiO₂ for their products.

Market Trends and Demand

titanium dioxide rutile supplier

The demand for titanium dioxide rutile is witnessing an upward trend across multiple sectors. The construction industry, driven by infrastructure development and technological advancements, is a significant consumer of rutile TiO₂ for paints and coatings. Furthermore, the growing awareness of environmental sustainability and the shift towards eco-friendly products propel demand in the cosmetics and personal care industry as well.

Moreover, the rise of innovative applications, such as the use of titanium dioxide in photocatalytic coatings and self-cleaning surfaces, underscores the need for adept suppliers. Additionally, advancements in solar technology using TiO₂ in photovoltaic cells are set to create new market opportunities, reinforcing the essential role of suppliers in this evolving landscape.

Challenges Faced by Suppliers

While the prospects for titanium dioxide rutile suppliers are promising, they also face several challenges. Fluctuating raw material costs, environmental regulations, and trade tariffs can impact the supply chain's stability. Suppliers must navigate these challenges while maintaining quality and competitive pricing.

Additionally, the push towards more sustainable supply chains compels suppliers to adopt greener practices. Innovations in production methods, waste management, and sourcing sustainable materials are becoming imperative for suppliers to remain relevant in the market.

The Future of Titanium Dioxide Rutile Suppliers

Looking ahead, the future of titanium dioxide rutile suppliers appears bright, driven by innovation and evolving market needs. Suppliers that prioritize sustainability, invest in advanced technologies, and build strong relationships with manufacturers and customers will likely thrive. The emphasis on high-quality products and exceptional service will continue to shape the competitive landscape.

In conclusion, titanium dioxide rutile suppliers play an integral role in various industries by providing high-quality materials critical for countless applications. As demand grows and industries evolve, these suppliers must adapt and innovate to meet the needs of their customers while adhering to sustainability standards. Their contributions will undoubtedly shape the future of manufacturing and product development across the globe.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025