Desemba . 27, 2024 03:20 Back to list

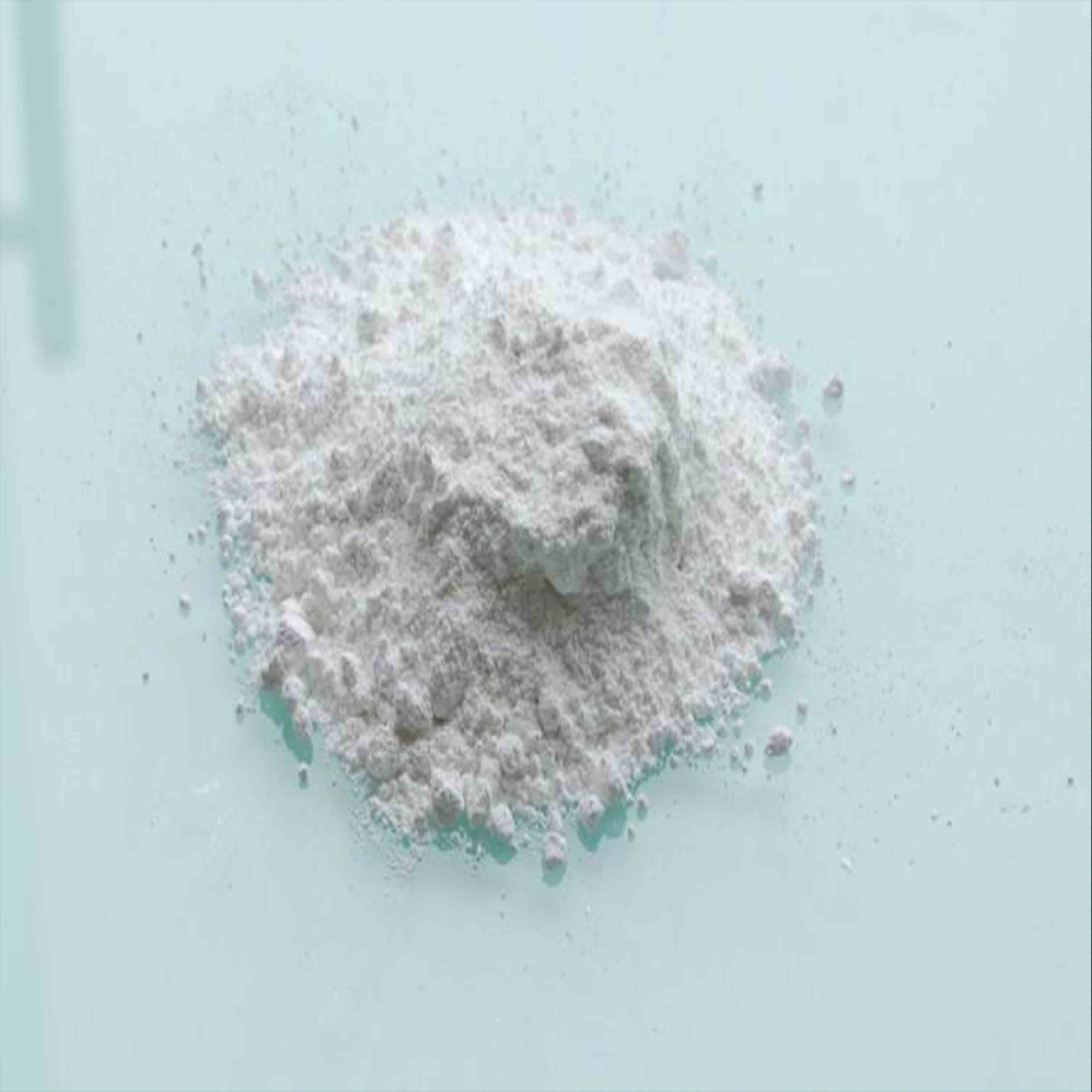

micronized titanium dioxide factory

The Rise of Micronized Titanium Dioxide Factories

In recent years, the demand for high-quality micronized titanium dioxide (TiO2) has surged, primarily due to its versatile applications across various industries. Micronized titanium dioxide, noted for its fineness and effectiveness as a pigment, has become a key ingredient in sectors such as paints, coatings, plastics, cosmetics, and even food products. This article delves into the burgeoning sector of micronized titanium dioxide factories, exploring their significance, production processes, and future prospects.

What is Micronized Titanium Dioxide?

Micronized titanium dioxide is a refined version of titanium dioxide that has been processed into fine particles, typically ranging from 1 to 10 microns in size. This small particle size enhances its performance, making it ideal for use as a whitening agent and opacifier. It reflects UV light, providing protection against harmful rays in sunscreen products, while also enhancing the brightness and durability of paints.

The Production Process

The manufacturing of micronized titanium dioxide involves several key stages. It begins with the extraction of titanium ore, which is then refined into titanium dioxide through various chemical processes. The next step is to micronize the titanium dioxide particles, which can be achieved through milling or other grinding techniques. This micronization process is critical, as it influences the particle size distribution, surface area, and overall performance of the final product.

Advanced factories employ cutting-edge technologies and equipment to ensure optimal production processes. The use of high-energy milling techniques, jet milling, and other modern methods enables manufacturers to produce uniform particle sizes, improving the consistency and quality of the titanium dioxide. Moreover, factories focus on environmental sustainability by implementing processes that minimize waste and energy consumption, making their operations both economically and ecologically viable.

Industrial Applications

micronized titanium dioxide factory

Micronized titanium dioxide finds extensive use in multiple industries. In the paint and coatings industry, it is prized for its ability to improve opacity, brightness, and UV protection. The plastics industry benefits from its inclusion to enhance the durability and aesthetic appeal of products. In cosmetics, titanium dioxide serves as a pigment and a sunscreen agent, helping protect skin from UV rays while providing a smooth texture.

Moreover, the food industry utilizes food-grade titanium dioxide as a colorant, enhancing the visual appeal of products like candies, sauces, and dairy items. Its non-toxic nature makes it a preferred choice, complying with food safety regulations.

Market Outlook

The future of micronized titanium dioxide factories appears promising. The global shift towards sustainable and eco-friendly products has sparked an increased demand for high-performance materials that comply with environmental standards. As industries evolve, the requirement for advanced and efficient production methods is becoming paramount.

Investment in research and development is vital to further improve the properties of micronized titanium dioxide and explore new applications. Innovations such as nanotechnology may also open up new avenues for its use, particularly in advanced materials and nanocomposites.

Conclusion

The establishment of micronized titanium dioxide factories represents a significant advancement in the manufacturing sector, responding to the growing global demand for high-quality materials. These factories not only contribute to various industries but also pave the way for sustainable production practices. As technology continues to evolve, the possibilities for micronized titanium dioxide are boundless, ensuring that it remains an essential component across diverse applications, from industrial to consumer products. Embracing innovation and sustainability will be crucial in shaping the future of this dynamic industry.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025