Novemba . 07, 2024 14:06 Back to list

Comparison of China’s Rutile and Anatase Titanium Dioxides for Industrial Applications

Comparing Rutile and Anatase The Two Polymorphs of Titanium Dioxide in China

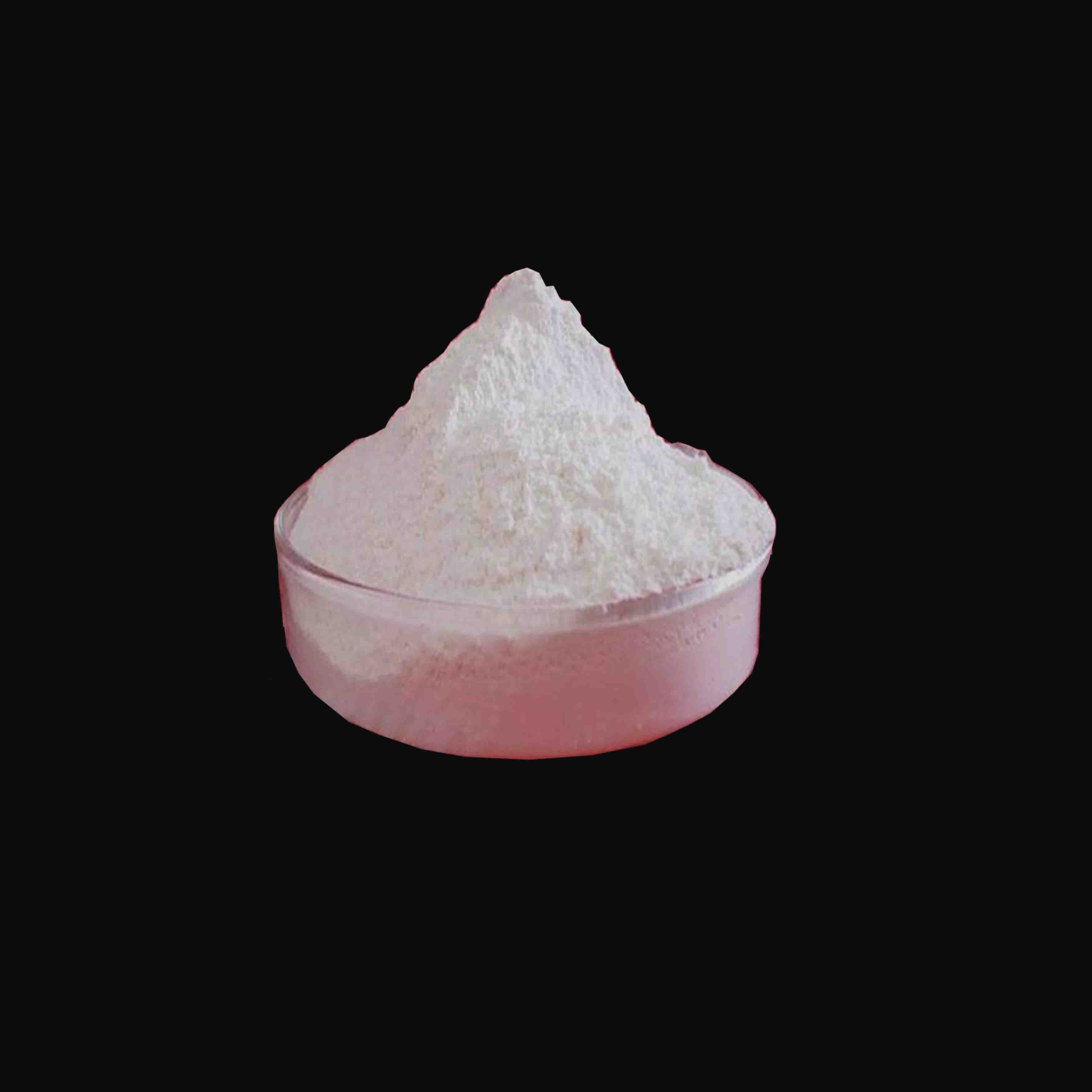

Titanium dioxide (TiO2) is one of the most widely used materials in the world, known for its excellent properties such as high refractive index, UV resistance, and photocatalytic activity. Two of the most significant polymorphs of titanium dioxide are rutile and anatase, each possessing unique characteristics that make them suitable for various applications. In recent years, the production and utilization of these two forms of TiO2 have become a focal point in China, influencing industries ranging from pigments to photocatalysts.

Rutile and Anatase Structural Differences

Rutile and anatase are both crystalline forms of titanium dioxide but differ in their crystal structures. Rutile has a tetragonal crystal system and is denser with a higher refractive index, typically around 2.7. Anatase, on the other hand, also has a tetragonal structure but is less dense and exhibits a lower refractive index of about 2.5. This difference in structure accounts for the variations in their physical and chemical properties, influencing their applications in different fields.

Applications of Rutile and Anatase

Rutile is predominantly used in the production of pigments, primarily for paints, coatings, and plastics due to its excellent opacity and durability. Its high resistance to degradation under UV light makes it a preferred choice for outdoor applications. In contrast, anatase is often utilized in photocatalysis, particularly in environmental applications such as water purification and air quality improvement. Its higher surface area and reactivity under sunlight make it more efficient in catalyzing reactions that decompose organic pollutants.

In China, the demand for titanium dioxide has surged in recent years, driven by rapid industrialization and urbanization. The pigment market remains a significant consumer of rutile, while the rise of environmentally friendly technologies has bolstered the demand for anatase. Chinese manufacturers are increasingly focusing on improving the quality and production efficiency of both forms of titanium dioxide to meet domestic and international market needs.

china rutile vs anatase

Economic Aspect and Production

China is one of the largest producers and consumers of titanium dioxide, with extensive mining and manufacturing capabilities. The country’s production methods have evolved from traditional processes to more advanced techniques, such as the sulfate and chloride methods, which can produce both rutile and anatase. However, environmental regulations are becoming stricter, pushing manufacturers to adopt cleaner technologies to minimize pollution and waste.

Rutile production is often associated with higher costs due to the need for advanced processing techniques, while anatase can be produced at lower costs but may require post-treatment for specific applications. As a result, the pricing strategies for these two forms of titanium dioxide differ, affecting their market dynamics and competitive landscape.

Future Trends and Challenges

Looking ahead, the global shift towards sustainability and green technologies will continue to impact the future of rutile and anatase production in China. There is a growing trend for using titanium dioxide in solar cells, which predominantly utilize anatase due to its semiconductor properties. Furthermore, the development of hybrid materials combining both rutile and anatase could pave the way for innovative applications.

However, challenges remain, such as managing the environmental impacts of titanium dioxide production and ensuring compliance with international standards. As China seeks to position itself as a leader in the global titanium dioxide market, balancing economic growth with environmental sustainability will be crucial.

In conclusion, both rutile and anatase play vital roles in various industries, particularly in China. Understanding their differences and applications can help in harnessing their capabilities effectively, paving the way for advancements in technology and sustainability. The ongoing evolution in production methods and market demands will shape the future of these two essential titanium dioxide polymorphs.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025