nov . 02, 2024 22:58 Back to list

tio2 equipment

The Importance of TiO2 Equipment in Modern Industries

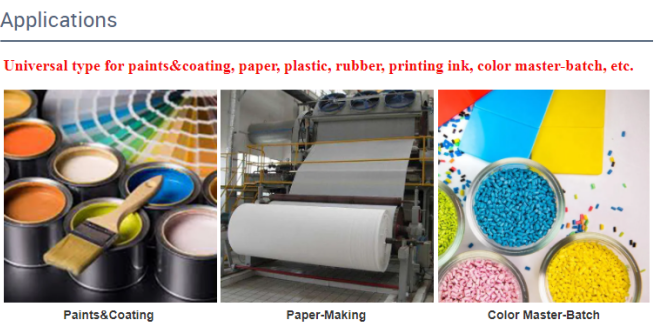

Titanium dioxide (TiO2) is a pivotal compound used in various industries including paints, plastics, textiles, and cosmetics due to its excellent opacity, brightness, and durability. The manufacturing of TiO2 involves several intricate processes that require specialized equipment to ensure efficiency, quality, and safety. Understanding the significance of TiO2 equipment not only highlights its role in production but also its impact on environmental sustainability.

The Importance of TiO2 Equipment in Modern Industries

Conversely, the chloride process is known for being more eco-friendly and efficient, involving the use of titanium ore with chlorine gas. This technique requires specialized chlorination reactors and filtration systems to separate impurities from the TiO2. Advanced filtration systems not only improve product quality by removing unwanted particles but also enhance operational efficiency by recycling materials within the process.

tio2 equipment

Furthermore, the handling of TiO2 during and after production calls for robust packaging and transportation equipment. TiO2 is often processed into a fine powder, which can be hazardous if inhaled. Therefore, manufacturers must use equipment that complies with safety regulations, featuring dust suppression systems and specialized containers to minimize exposure to workers and the environment.

In addition to manufacturing and handling equipment, there is a growing need for analytical instruments in the TiO2 industry. Quality control is paramount in ensuring that the end product meets industry standards. Equipment such as spectrometers and particle size analyzers play a crucial role in analyzing the composition and performance characteristics of TiO2, aiding manufacturers in producing high-quality materials.

Moreover, the market for TiO2 is expanding rapidly, driven by increasing demand in emerging sectors such as renewable energy, where TiO2 is used in photovoltaics. This growth necessitates ongoing advancements in TiO2 equipment to improve efficiency, reduce costs, and minimize environmental impacts.

In conclusion, the equipment used in the production and handling of TiO2 is critical for maintaining high standards of quality, safety, and environmental compliance. As industries continue to evolve, so too will the technology surrounding TiO2, further solidifying its role as an indispensable material in modern applications. Emphasizing the importance of investing in advanced TiO2 equipment will not only foster innovation but also promote sustainability within the industry.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025