okt . 22, 2024 03:32 Back to list

Rutile Type TiO2 Manufacturing Process and Quality Assessment for Enhanced Applications

Understanding the Rutile-Type TiO2 Factory Production, Applications, and Sustainability

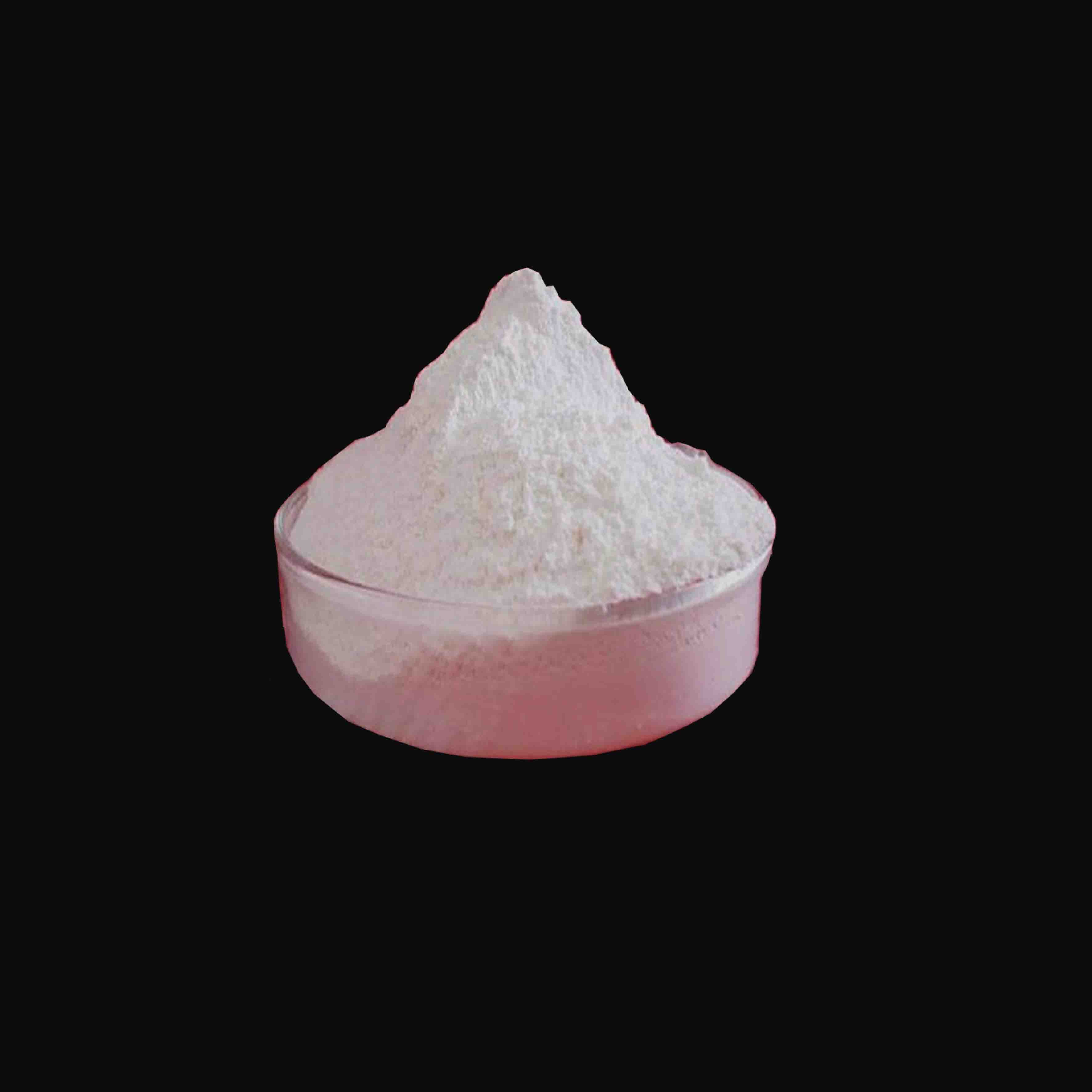

Rutile, a mineral composed primarily of titanium dioxide (TiO2), is a critical raw material for numerous industrial applications. The production of rutile-type TiO2 in factories involves sophisticated processes to extract and refine titanium, leading to a host of products that significantly impact various sectors. This article delves into the intricacies of a rutile-type TiO2 factory, exploring its production methods, applications, and the push towards sustainability.

Production Processes

The production of rutile-type TiO2 generally follows two main pathways the sulfate process and the chloride process. Both methods start from titanium ore, predominantly rutile or ilmenite, a titanium-rich mineral.

1. Sulfate Process This traditional method involves the digestion of ilmenite ore with sulfuric acid. The reaction produces titanium sulfate, which is then hydrolyzed to form hydrated titanium dioxide. After filtration and washing, the titanium dioxide is calcined at high temperatures to produce the final rutile product. This process generates significant amounts of waste, particularly iron sulfate, which poses environmental challenges.

2. Chloride Process This increasingly popular method uses titanium feedstock, such as rutile or modified ilmenite, and involves chlorine gas. The feedstock is reacted with chlorine at high temperatures to produce titanium tetrachloride (TiCl4). This compound is then purified and subjected to reduction with molten magnesium or sodium, resulting in metallic titanium and titanium dioxide. The chloride process is considered more environmentally friendly since it generates less waste and allows for the recycling of byproducts.

Both processes require stringent quality control and advanced technology to ensure the production of high-purity rutile, which is essential for meeting the demands of various industries.

Applications of Rutile-Type TiO2

Rutile-type TiO2 is widely recognized for its outstanding properties, particularly its high refractive index and excellent UV resistance. These characteristics make it an invaluable ingredient in many products

- Paints and Coatings Rutile TiO2 is the leading pigment in paints, providing excellent coverage and brightness. Its durability and resistance to fading make it an ideal choice for both interior and exterior applications.

rutiletypetio2 factory

- Plastics In the plastic industry, rutile-type TiO2 enhances the opacity and whiteness of products. It is commonly used in the production of polypropylene, polyethylene, and other polymers.

- Cosmetics The cosmetics industry employs rutile TiO2 for its ability to scatter UV light, providing a protective barrier in sunscreens and other skincare products

.- Photovoltaics Recent advancements have seen rutile-type TiO2 gaining traction in the field of solar energy. Its semiconductor properties are being utilized in the development of photovoltaic cells, contributing to renewable energy solutions.

- Ceramics Rutile TiO2 is added to ceramics to improve their mechanical properties and aesthetics, making it suitable for high-quality porcelain and tiles.

Sustainability Challenges and Innovations

Despite its myriad applications, the production of rutile-type TiO2 poses significant environmental challenges. The sulfate process is particularly scrutinized for its waste generation and potential pollution. Consequently, the industry is shifting towards more sustainable practices.

Innovations in recycling technologies are emerging as effective solutions. Many factories are now exploring ways to recycle waste materials generated during production, such as iron sulfate. Meanwhile, the transition to the chloride process, while requiring substantial infrastructure investment, offers a pathway to lower environmental impact due to its efficiency.

Furthermore, companies are increasingly adopting sustainable sourcing practices, ensuring that the titanium ore used in production is extracted responsibly, considering both ecological and social factors.

Conclusion

Rutile-type TiO2 factories play a pivotal role in the global economy, supplying essential materials for a diverse range of applications. As the industry evolves, the focus on sustainable practices becomes paramount. By embracing innovative production methods and responsible sourcing, the rutile TiO2 sector can minimize its ecological footprint while continuing to meet the demands of modern industries. The future of rutile-type TiO2 appears bright, with a commitment to sustainability paving the way for continued growth and innovation.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025