dec . 06, 2024 08:11 Back to list

Rutile Grade Titanium Dioxide Surface Treatment for Plastic Manufacturing Applications

The Role of Rutile Grade Organic Surface Treatment Titanium Dioxide in Enhancing Plastic Products

In the realm of plastic manufacturing, the choice of materials significantly influences the quality, durability, and aesthetics of the final products. One critical component that has been gaining traction in recent years is titanium dioxide (TiO2), specifically in its rutile grade form. The functionality and integration of rutile grade titanium dioxide treated with organic surfaces are proving to be game-changers in the plastic industry, enhancing both performance and versatility of plastic materials.

Rutile is one of the primary natural forms of titanium dioxide, renowned for its excellent opacity, brightness, and photo-stability. These properties make rutile grade titanium dioxide an ideal pigment for various applications, particularly in the plastics sector. However, to maximize its potential, it often undergoes organic surface treatments. These treatments enhance its compatibility with organic substrates, facilitating better dispersion in various polymer matrices.

One of the 주요 장점 of using organic surface-treated rutile titanium dioxide is its ability to improve the mechanical properties of plastic products. When integrated into plastic formulations, it can significantly enhance tensile strength and impact resistance, which are crucial for products used in challenging environments. This improvement in mechanical properties helps manufacturers produce more robust and reliable products that can withstand rigorous usage.

Moreover, organic surface treatment aids in the dispersion of TiO2 particles within the plastic matrix. Uneven dispersion of pigment can lead to inconsistencies in color and decreased performance of the final products. With a treated rutile titanium dioxide, manufacturers achieve a uniform distribution, resulting in consistently high-quality products with superior aesthetics. This uniform coloration is particularly important in consumer-facing applications, where appearance is often tied directly to perceived product quality.

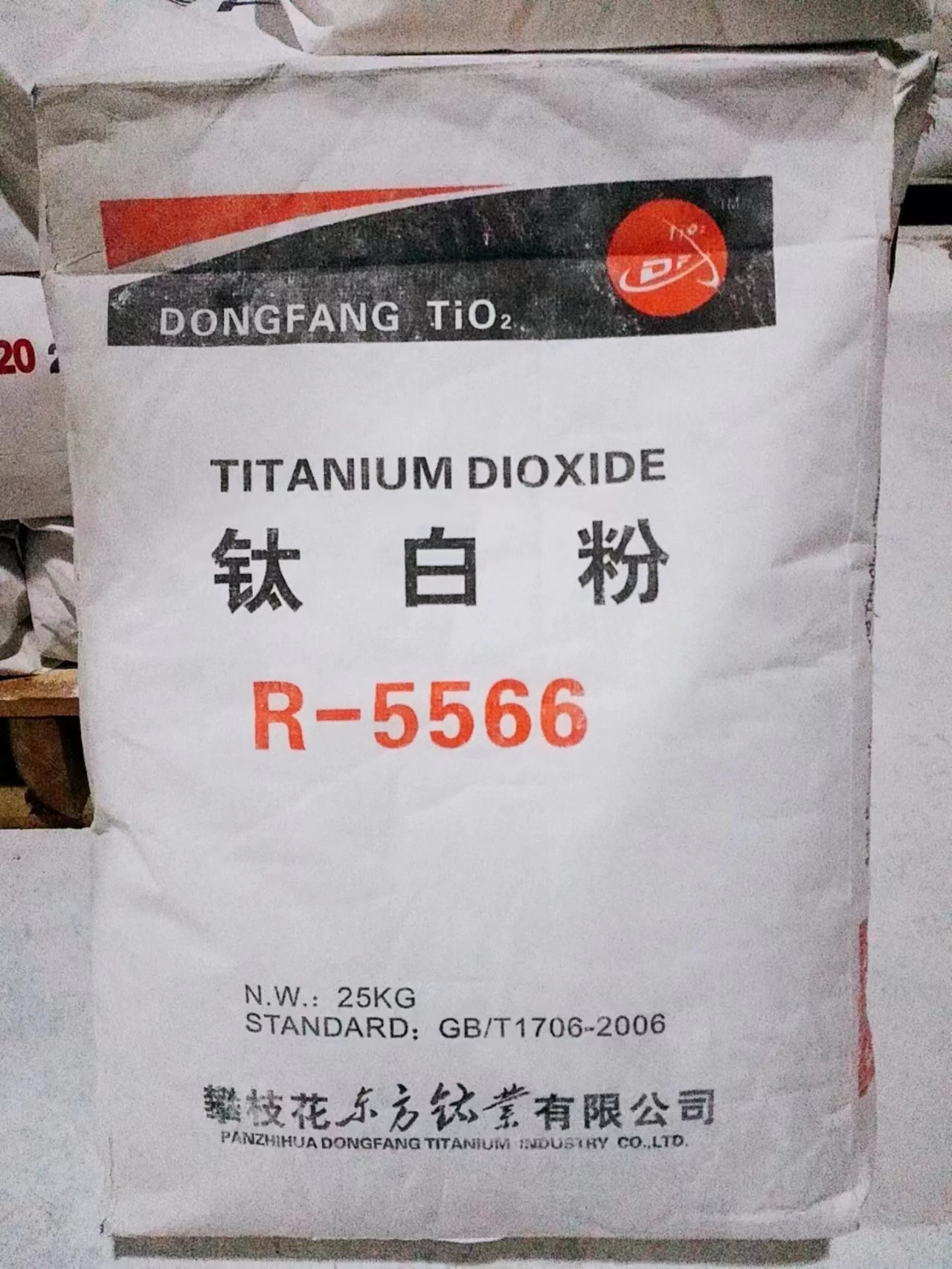

rutile grade organic surface treatment titanium dioxide for plastic factory

In addition to aesthetics and mechanical properties, the use of rutile grade titanium dioxide can impart enhanced UV stability to plastics. Many plastics are prone to degradation when exposed to ultraviolet light, which can lead to discoloration, brittleness, and eventual failure. The incorporation of treated TiO2 not only protects the plastic from UV radiation but also maintains its structural integrity and appearance over extended periods, thus extending the product lifespan and reducing the cost of replacement or repairs.

Sustainability is another critical consideration in modern manufacturing. The market is increasingly shifting towards environmentally friendly materials and practices. Rutile grade titanium dioxide derived from sustainable sources presents a great option for manufacturers aiming to reduce their environmental footprint. When utilized wisely, it can contribute to the creation of eco-friendly plastics, appealing to an environmentally conscious consumer base.

Furthermore, as regulators become stricter regarding chemical safety, utilizing organic surface-treated titanium dioxide can help plastic manufacturers meet such regulatory requirements. The treatment process often reduces the potential for leaching hazardous substances, thereby ensuring that the end products are safer for consumers.

In conclusion, the integration of rutile grade organic surface treatment titanium dioxide into plastic manufacturing is transforming the industry. Its ability to enhance mechanical properties, improve UV resistance, and ensure consistent product quality makes it a valuable addition to any plastic formulation. Moreover, its potential for improving sustainability aligns well with the growing demand for eco-friendly products. As the industry continues to evolve, the role of treated titanium dioxide will likely become even more significant, paving the way for innovations that prioritize both performance and safety in plastic products.

For manufacturers, the advantages offered by rutile grade titanium dioxide extend beyond mere aesthetics; they encapsulate a commitment to quality, durability, and responsibility towards both consumers and the environment. Embracing such materials is not just a trend but a step forward towards a more sustainable and reliable future in plastic manufacturing.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025