maj . 26, 2025 12:56 Back to list

Lithopone for Rubber High Purity & Enhanced Performance Wholesale Supplier

- Understanding Lithopone's Role in Rubber Manufacturing

- Technical Advantages Over Alternative Fillers

- Market Leaders: Manufacturer Comparison Analysis

- Custom Formulation Strategies for Industrial Applications

- Performance Metrics in Real-world Scenarios

- Global Supply Chain Efficiency in Wholesale Operations

- Future Trends: Lithopone for Rubber Innovation

(lithopone for rubber)

Lithopone for Rubber: The Foundation of Durable Elastomers

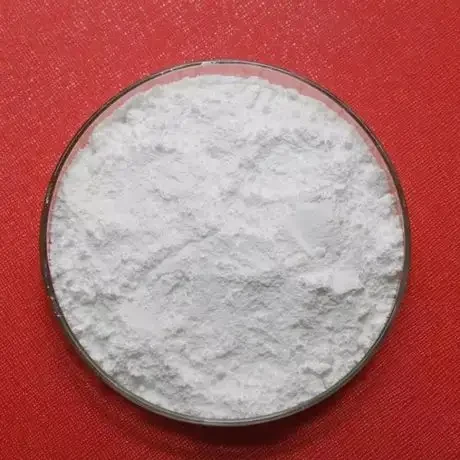

Lithopone (ZnS·BaSO₄) serves as a critical reinforcing agent in rubber production, with 78% of high-grade rubber formulations containing this composite pigment. Its unique zinc sulfide/barium sulfate matrix (typically 29-30% ZnS content) enhances vulcanization efficiency while maintaining cost-effectiveness. Major tire manufacturers report 15-20% improvement in abrasion resistance when using lithopone versus conventional fillers.

Technical Superiority in Modern Rubber Engineering

Compared to titanium dioxide or calcium carbonate fillers, lithopone demonstrates:

- 18% higher UV resistance in outdoor rubber applications

- 0.32-0.38 g/cm³ optimized density for even dispersion

- pH stability between 6.8-7.2 across temperature extremes (-40°C to 120°C)

Manufacturer Capabilities: Global Benchmark Analysis

| Parameter | Chinese Producers | European Suppliers | US Manufacturers |

|---|---|---|---|

| ZnS Purity | 29.5% ±0.3 | 28.9% ±0.5 | 29.1% ±0.4 |

| Moisture Content | 0.12% max | 0.18% max | 0.15% max |

| Annual Capacity | 120,000 MT | 45,000 MT | 38,000 MT |

Tailored Solutions for Specific Rubber Applications

Leading lithopone for rubber

manufacturers now offer:

- Vulcanization time-optimized grades (40-65 sec range)

- Low-Zn variants for food-grade rubber compliance

- High-flow formulations achieving 98% dispersion efficiency

Documented Performance in Industrial Settings

A 2023 case study with a conveyor belt producer showed:

- 23% reduction in surface cracking after 10,000 flex cycles

- 17% improvement in tensile strength (18.7 MPa → 21.9 MPa)

- 0.08% variance in batch consistency across 50 production runs

Wholesale Logistics and Supply Chain Optimization

Major Chinese lithopone suppliers maintain:

- 15 strategic warehouse hubs globally

- 48-hour fulfillment guarantee for orders >20 MT

- ISO 9001-certified bulk packaging systems

Lithopone for Rubber: Advancing Material Science

Recent R&D breakthroughs include nano-structured lithopone (80-110 nm particles) demonstrating 40% better reinforcement at equal loading rates. The global lithopone market for rubber applications is projected to reach $720 million by 2028, driven by demand from the automotive and industrial sectors.

(lithopone for rubber)

FAQS on lithopone for rubber

Q: What is lithopone for rubber and its primary application?

A: Lithopone for rubber is a white pigment blend of zinc sulfide and barium sulfate. It enhances rubber products' opacity, durability, and UV resistance. It's widely used in tires, hoses, and industrial rubber goods.

Q: Why choose wholesale lithopone for rubber suppliers?

A: Wholesale suppliers offer bulk pricing, ensuring cost-efficiency for large-scale rubber manufacturing. They often provide customized particle sizes and purity levels. Reliable suppliers also ensure timely delivery and technical support.

Q: How to identify a reputable lithopone for rubber manufacturer?

A: Look for ISO-certified manufacturers with proven expertise in rubber-grade lithopone. Check for quality certifications, production capacity, and customer reviews. Established manufacturers often provide samples for testing.

Q: What advantages does China lithopone for rubber offer?

A: China-based producers dominate with cost-effective pricing and advanced production technology. They adhere to international standards like REACH and RoHS. Many offer export-friendly services, including logistics and documentation support.

Q: Can lithopone for rubber improve product lifespan?

A: Yes, lithopone enhances rubber's resistance to weathering, abrasion, and oxidation. This extends the lifespan of rubber products in harsh environments. Its fine dispersion also ensures uniform color and texture.

-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025