hot sale tio2 rutile lomon r996 manufacturers

Фев . 14, 2025 03:06 Back to list

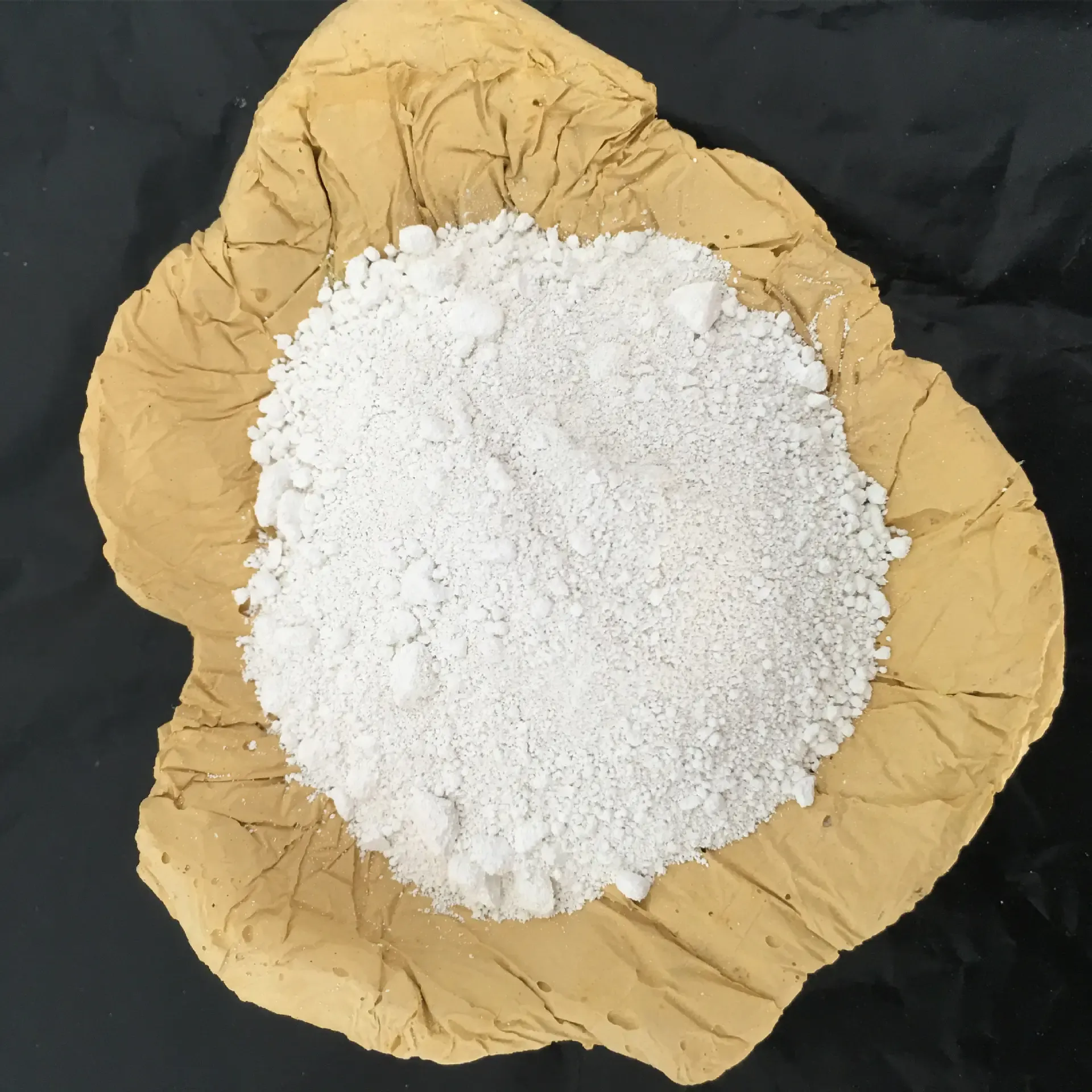

hot sale tio2 rutile lomon r996 manufacturers

Titanium dioxide (TiO2) in its rutile form stands as a cornerstone in the vast field of manufacturing due to its exceptional properties. Its popularity among manufacturers is primarily sparked by its superior durability, high refractive index, and stability under ultraviolet light. This has propelled not just its use, but its demand across multiple industries, making the choice of a reliable TiO2 rutile manufacturer a pivotal decision for businesses seeking quality and consistency in their products.

It’s also important to consider the environmental impact of TiO2 production. Manufacturers committed to sustainable practices demonstrate their authority by employing environmentally friendly techniques in the extraction and processing of raw materials. This can include the recycling of water in production processes or the reduction of hazardous emissions. When companies take tangible steps to minimize their environmental footprint, they not only comply with global environmental standards but also appeal to industries that prioritize sustainability. Moreover, real-world experience serves as a valuable asset. Manufacturers that have been in the industry for decades often possess a wealth of practical insights into market trends and customer demands. They are better positioned to anticipate changes and provide consistently high-quality products over time. Such experience also means that these companies have refined their logistics and customer service operations to ensure efficiency in supply chain management. Additionally, reviews and testimonials from long-term partners can provide invaluable insight into a manufacturer’s reliability. Companies that maintain long-standing relationships with clients often demonstrate a high level of trustworthiness and commitment to customer satisfaction. Ultimately, selecting a TiO2 rutile type manufacturer requires a balanced consideration of expertise, experience, and environmental responsibility. It’s about ensuring the manufacturer can deliver both on quality and innovation while maintaining ethical production practices. Making this choice wisely not only enhances product quality but also fortifies a company’s standing in an increasingly competitive marketplace.

It’s also important to consider the environmental impact of TiO2 production. Manufacturers committed to sustainable practices demonstrate their authority by employing environmentally friendly techniques in the extraction and processing of raw materials. This can include the recycling of water in production processes or the reduction of hazardous emissions. When companies take tangible steps to minimize their environmental footprint, they not only comply with global environmental standards but also appeal to industries that prioritize sustainability. Moreover, real-world experience serves as a valuable asset. Manufacturers that have been in the industry for decades often possess a wealth of practical insights into market trends and customer demands. They are better positioned to anticipate changes and provide consistently high-quality products over time. Such experience also means that these companies have refined their logistics and customer service operations to ensure efficiency in supply chain management. Additionally, reviews and testimonials from long-term partners can provide invaluable insight into a manufacturer’s reliability. Companies that maintain long-standing relationships with clients often demonstrate a high level of trustworthiness and commitment to customer satisfaction. Ultimately, selecting a TiO2 rutile type manufacturer requires a balanced consideration of expertise, experience, and environmental responsibility. It’s about ensuring the manufacturer can deliver both on quality and innovation while maintaining ethical production practices. Making this choice wisely not only enhances product quality but also fortifies a company’s standing in an increasingly competitive marketplace.

Latest news

-

Rutile Titanium Dioxide for Paint Factories: Premium Industrial Grade Tio2

NewsAug.09,2025

-

Premium Titania TiO2 Manufacturer & Supplier

NewsAug.08,2025

-

Wholesale Titania TiO2 | Factory Direct Suppliers & Manufacturers

NewsAug.07,2025

-

R996 TiO2: High Performance Rutile Titanium Dioxide

NewsAug.06,2025

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025