Дек . 12, 2024 10:32 Back to list

coating raw material factory

The Importance of Raw Materials in Coating Manufacturing

In the realm of manufacturing, especially within sectors such as automotive, construction, and consumer goods, the significance of high-quality coatings cannot be overstated. These coatings play a pivotal role in enhancing aesthetics, protecting surfaces, and improving durability. At the heart of producing these coatings lies the sourcing and processing of raw materials. This article explores the critical role that raw materials play in coating factories and highlights their impact on the overall quality and performance of the final products.

Understanding Coating Composition

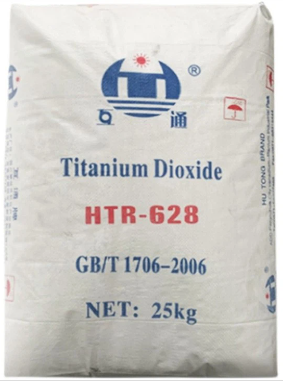

Coatings are formulated from a variety of materials, each serving a unique purpose. The primary components typically include binders, pigments, solvents, and additives. Binders are crucial as they provide adhesion to the substrate and form a continuous film when the coating dries. Pigments not only impart color but also enhance properties such as opacity and UV resistance. Solvents ensure that the coating remains in a manageable liquid state during application and facilitate a smooth drying process. Lastly, additives can modify specific characteristics like flow, leveling, and durability.

Raw Materials Procurement

The journey of crafting an exceptional coating begins with the procurement of raw materials. Coating factories invest heavily in sourcing high-quality raw materials that meet stringent industry standards. This process involves working closely with suppliers to ensure that materials are not only pure but also consistent in quality. Factors such as availability, cost, and environmental impact are also taken into consideration, making raw material procurement a complex yet crucial aspect of coating production.

Quality Control and Testing

coating raw material factory

Once raw materials reach the factory, they undergo rigorous quality control and testing procedures. This might include assessing the particle size of pigments, checking the viscosity of binders, or evaluating the evaporation rates of solvents. These tests ensure that the materials meet the specifications required for the desired coating performance. Rigorous quality control measures minimize batch-to-batch variation, which is essential for maintaining the reliability and reputation of the coating brand.

Formulation and Production

With verified raw materials, the next step is formulation. This process involves precisely measuring and mixing the components to achieve the desired properties of the coating. Skilled chemists and formulators work collaboratively to adjust ratios, modify compositions, and innovate new formulations that cater to specific applications, whether it be a high-gloss automotive finish or a matte architectural coating. The expertise in balancing raw materials ultimately dictates the performance of the final product.

Environmental Considerations

In today’s world, the environmental impact of raw materials used in coatings has become a significant concern. Leading coating manufacturers are increasingly opting for sustainable raw materials such as bio-based resins, low-VOC (volatile organic compound) solvents, and recyclable pigments. More than ever, coating factories are committed to reducing their carbon footprint and developing products that align with global sustainability goals. This shift not only benefits the planet but also resonates well with environmentally conscious consumers.

Conclusion

In conclusion, raw materials form the backbone of coating production in manufacturing. Their selection, quality, and formulation have a direct influence on the performance, durability, and visual appeal of coated surfaces. As industries continue to innovate and evolve, the emphasis on sourcing high-quality raw materials, coupled with sustainability initiatives, will play an essential role in shaping the future of coatings. Coating factories that prioritize these factors will be better positioned to meet the demands of a competitive market and contribute to a more sustainable future. The vital link between raw materials and coating performance is a testament to the intricate processes that underlie the manufacture of coatings, which are an indispensable part of myriad products we encounter daily.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025