Дек . 12, 2024 10:00 Back to list

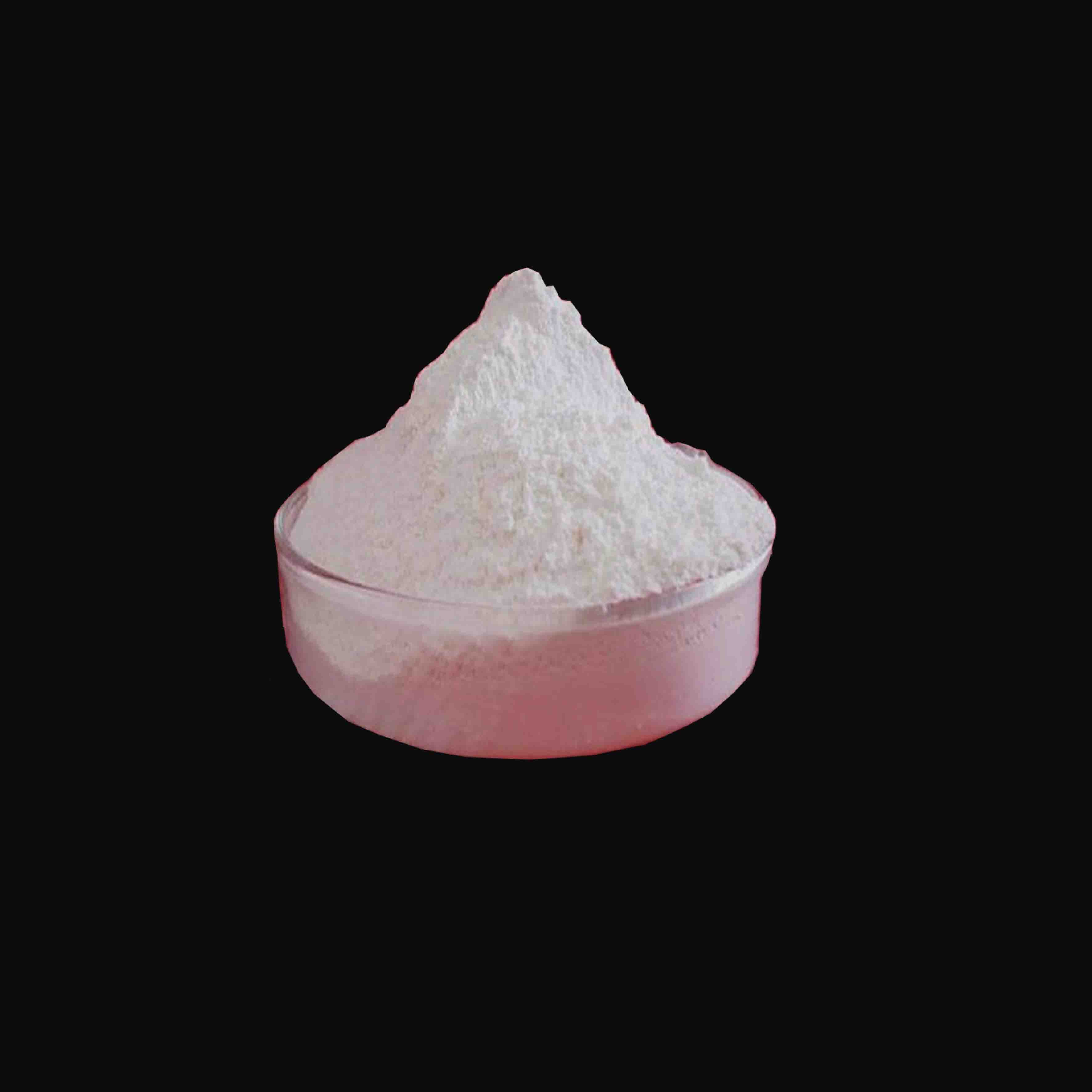

china conductive titanium powder

Conductive Titanium Powder A Rising Star in Material Science

In recent years, the field of material science has witnessed remarkable advancements, particularly in the development of conductive materials. Among these innovations, conductive titanium powder has emerged as a highly promising material due to its unique properties and wide range of applications. As industries seek lighter, stronger, and more efficient materials, conductive titanium powder has garnered significant attention, especially from sectors like aerospace, automotive, electronics, and biomedicine.

Properties and Characteristics of Conductive Titanium Powder

Conductive titanium powder is primarily characterized by its excellent conductivity and mechanical strength. Titanium, known for its lightweight nature and high strength-to-weight ratio, offers a compelling alternative to traditional conductive materials such as copper and aluminum. When processed into powder form, titanium showcases enhanced surface area, which significantly improves its conductivity. This attribute makes it highly desirable for various applications that require effective electrical conductivity while maintaining reduced weight.

Furthermore, titanium is highly resistant to corrosion, which extends the lifespan of products made from this material. This resistance to environmental degradation is particularly valuable in harsh conditions, making conductive titanium powder an excellent choice for aerospace components and marine applications. Additionally, it is bio-compatible, making it suitable for medical implants and devices, where the interaction with human tissue is crucial.

Production Techniques

The production of conductive titanium powder typically involves various methods, such as gas atomization, plasma atomization, and mechanical milling. Each technique has its advantages, and the choice often depends on the desired particle size, morphology, and the specific requirements of the intended application. Gas atomization, for instance, produces spherical particles that are highly desirable in powder metallurgy and additive manufacturing processes. Conversely, plasma atomization enables the production of finer powders that exhibit unique flow characteristics and enhanced densification properties when used in sintering processes.

The advanced production techniques allow for precise control over the properties of the titanium powder, ensuring that it meets the stringent criteria set by different industries. By fine-tuning parameters such as particle size distribution and purity, manufacturers can tailor the conductive titanium powder to suit specific applications, enhancing its versatility and effectiveness.

Applications of Conductive Titanium Powder

china conductive titanium powder

The applications of conductive titanium powder are vast and varied. In the electronics sector, it is utilized in the production of capacitors, sensors, and conductive adhesives. Its excellent conductivity, combined with lightweight properties, makes it an ideal choice for these applications, where performance and weight efficiency are crucial.

In the aerospace industry, conductive titanium powder finds use in manufacturing components that require both strength and electrical conductivity, such as light-weight connectors and electronic housings. The ability to withstand extreme temperatures and resist wear makes it suitable for the demanding conditions encountered in aerospace environments.

Moreover, in the field of biomedicine, conductive titanium powder is utilized in creating implants and prosthetic devices. Its biocompatibility ensures that these products are safe for interaction with human tissues, while its conductivity can enhance the performance of certain medical devices, particularly those involving electrical stimulation.

Future Developments

As technology progresses, the demand for efficient and sustainable materials continues to grow. Conductive titanium powder is likely to play an increasingly pivotal role in meeting these demands. Ongoing research in nanotechnology, for instance, aims to further enhance the properties of titanium powder, potentially leading to even greater levels of conductivity and mechanical performance.

Additionally, as industries embrace 3D printing and additive manufacturing techniques, the role of conductive titanium powder is expected to expand. The ability to create complex geometries and reduce waste in manufacturing processes aligns perfectly with the growing emphasis on sustainability within various sectors.

Conclusion

In conclusion, conductive titanium powder is carving a niche for itself in the realm of advanced materials. Its combination of lightweight, strength, and conductivity positions it as a critical player across multiple industries. As research and production methods continue to advance, the potential applications and benefits of conductive titanium powder are likely to expand, opening new avenues for innovation in technology and engineering. With its unique properties and versatile applications, conductive titanium powder undoubtedly stands at the forefront of material science's evolution.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025