nov. . 17, 2024 04:58 Back to list

Titanium Dioxide Production Facility Overview and Innovative Manufacturing Processes

Titanium Dioxide Manufacturing The Role of Titan Tio2 Factory

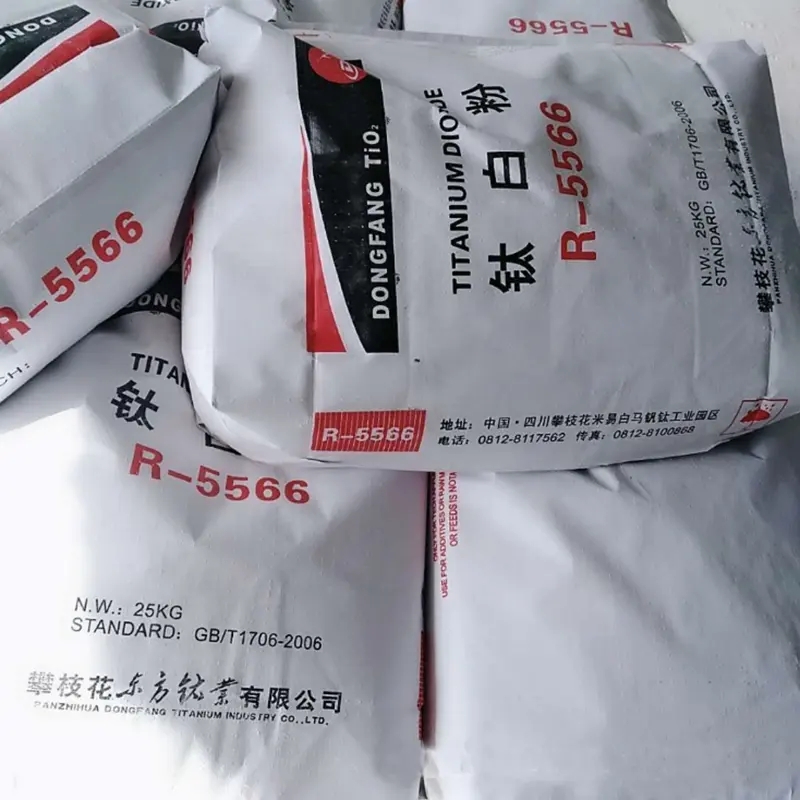

Titanium dioxide, commonly known as TiO2, is one of the most widely used white pigments in various industries, including paints, coatings, plastics, and even food products. Its exceptional brightness and opacity make it a valuable additive for these applications. Among various manufacturers, Titan TiO2 Factory stands out for its commitment to quality and innovation in the production of titanium dioxide.

The process of manufacturing titanium dioxide typically involves two primary methods the sulfate process and the chloride process. The sulfate process is the traditional method, where ilmenite ore is treated with sulfuric acid to produce titanium dioxide pigments. On the other hand, the chloride process has gained popularity due to its efficiency and lower environmental impact. In this method, titanium-containing ores are converted into titanium tetrachloride (TiCl4) through chlorination, which is then oxidized to produce high-purity titanium dioxide.

Titanium Dioxide Manufacturing The Role of Titan Tio2 Factory

One of the significant advantages of TiO2 produced at Titan TiO2 Factory is its versatility. The factory manufactures a range of TiO2 grades tailored to specific applications, such as paints, coatings, plastics, paper, and ceramics. For the paint industry, for instance, the factory produces rutile-grade titanium dioxide, known for its exceptional hiding power and durability. In the plastics sector, the TiO2 pigments enhance the opacity and UV resistance of products, extending their lifespan.

titan tio2 factory

Environmental sustainability is a core value at Titan TiO2 Factory. The company is committed to reducing its carbon footprint and minimizing waste. Through continuous innovation and investment in sustainable technologies, Titan TiO2 Factory has implemented practices that reduce energy consumption and emissions during the manufacturing process. Furthermore, the factory actively seeks to recycle and repurpose waste materials, demonstrating a commitment to a circular economy.

In addition to environmental stewardship, Titan TiO2 Factory places a strong emphasis on research and development. The facility collaborates with academic institutions and industry partners to develop new formulations and applications for titanium dioxide. This focus on innovation allows the factory to stay ahead of market trends and respond to the evolving needs of customers across different sectors.

The global demand for titanium dioxide continues to rise, driven by the increasing use of eco-friendly paints, coatings, and plastics. Titan TiO2 Factory is well-positioned to meet this demand, leveraging its expertise, state-of-the-art manufacturing capabilities, and commitment to sustainability. As industries seek higher quality and more environmentally friendly materials, Titan TiO2 Factory remains a crucial player in the titanium dioxide market.

In conclusion, Titan TiO2 Factory exemplifies excellence in titanium dioxide manufacturing through its advanced production methods, commitment to quality, and focus on sustainability. As the demand for TiO2 grows, this factory stands ready to provide innovative solutions that enhance the performance of various products while minimizing environmental impact. With a solid foundation in research and development, Titan TiO2 Factory is poised to lead the way in the future of titanium dioxide production.

-

Premium Titania TiO2 Manufacturer & Supplier

NewsAug.08,2025

-

Wholesale Titania TiO2 | Factory Direct Suppliers & Manufacturers

NewsAug.07,2025

-

R996 TiO2: High Performance Rutile Titanium Dioxide

NewsAug.06,2025

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025