sept. . 21, 2024 13:02 Back to list

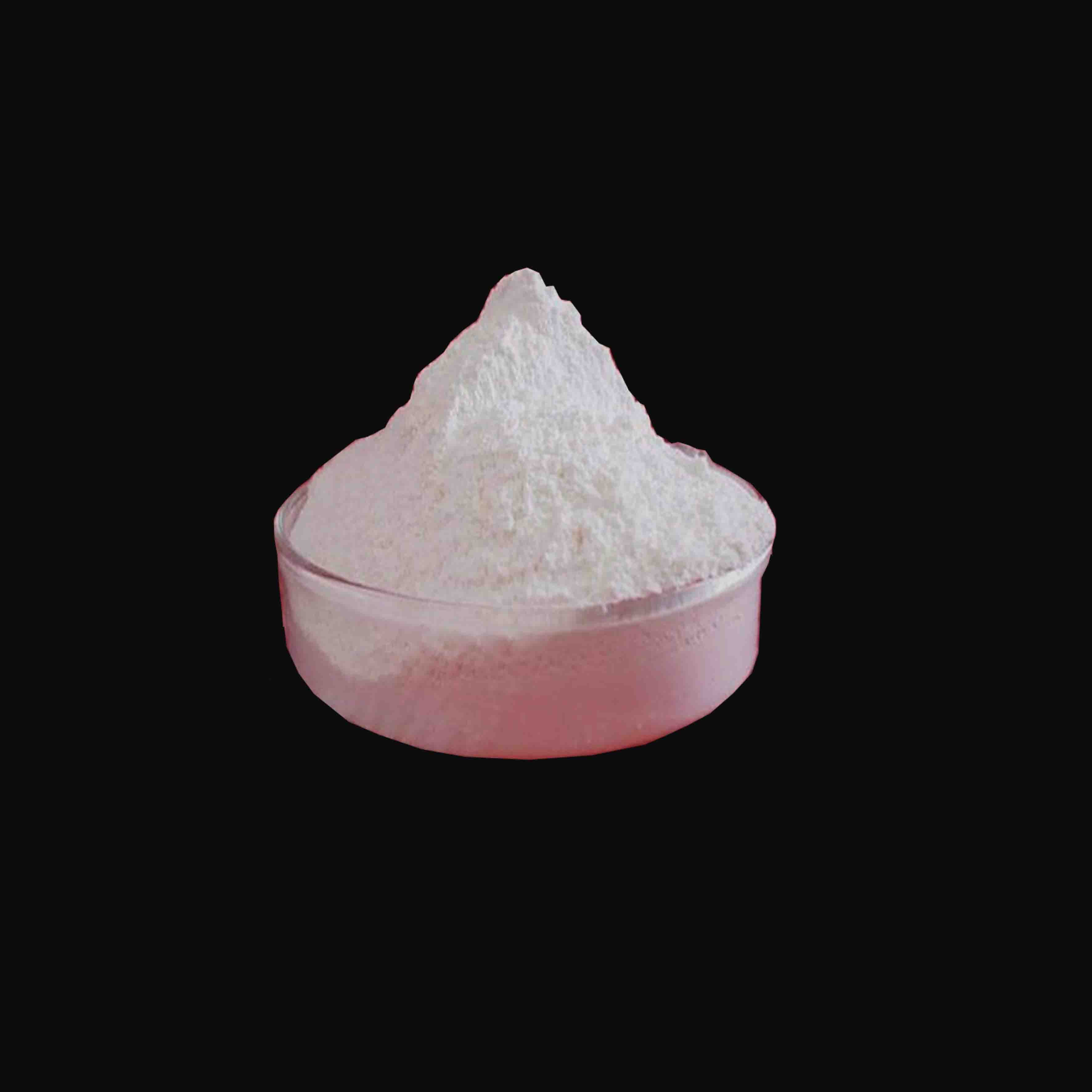

titanium iv oxide factory

Titanium IV Oxide Factory Pioneering the Future of Advanced Materials

As industries around the world increasingly focus on sustainability and efficiency, the demand for advanced materials has never been higher. Among these materials, titanium IV oxide (TiO2) stands out for its diverse applications and unique properties. A titanium IV oxide factory plays a pivotal role in producing this valuable compound, fueling advancements in various sectors including construction, electronics, and environmental technologies.

The Importance of Titanium IV Oxide

Titanium IV oxide, primarily known for its high refractive index and excellent thermal stability, is an essential component in a myriad of products. It is best known as a white pigment in paints, coatings, and plastics due to its ability to provide opacity and brightness. Moreover, TiO2 is widely used in the production of sunscreen and cosmetics because of its UV filtering properties, providing not only aesthetic benefits but also protection against harmful rays.

In addition to its pigmentary applications, titanium IV oxide plays a crucial role in the field of photocatalysis. When exposed to sunlight, TiO2 can facilitate chemical reactions that break down organic pollutants, making it an invaluable material for environmental remediation. This aspect of titanium IV oxide is increasingly important as businesses and governments seek methods to tackle pollution and improve air quality, underscoring the material's relevance in today's world.

The Factory Setup

Setting up a titanium IV oxide factory involves considerable planning and investment. The manufacturing process typically begins with the extraction of titanium ore, primarily ilmenite or rutile. These ores undergo refining processes such as the Sulfate or Chloride processes to produce high-purity titanium IV oxide.

titanium iv oxide factory

The operational efficiency of a titanium IV oxide factory is paramount. Advanced technologies and automation systems are employed to minimize waste, enhance product quality, and ensure safety protocols are observed. Additionally, the integration of eco-friendly practices, including the recycling of materials and reduction of carbon emissions, aligns with global sustainability goals.

Challenges and Innovations

Despite its promising market, the titanium IV oxide industry faces challenges. Fluctuations in raw material prices and stringent environmental regulations can impact production costs and operational feasibility. However, innovation within the industry is addressing these challenges. For instance, researchers are exploring novel methods of creating nano-sized titanium IV oxide particles that maintain the desirable properties of conventional TiO2 while expanding its application potential, such as in advanced battery systems and smart textiles.

The Future of Titanium IV Oxide Production

The future of titanium IV oxide factories appears bright. With technological advancements and a growing emphasis on sustainable practices, manufacturers are likely to enhance not only production efficiency but also the environmental footprint of their operations. Furthermore, as industries continue to expand their use of titanium IV oxide—from solar cells to water purification systems—the strategic positioning of these factories will be critical to meeting the rising global demand.

In conclusion, a titanium IV oxide factory stands not just as a production facility but as a catalyst for innovation and sustainability. As we venture further into the 21st century, the role of titanium IV oxide in shaping a cleaner, more efficient world cannot be overstated. The commitment to harnessing its potential while addressing the challenges of production will undoubtedly define the future of this essential material.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025