mai . 11, 2025 12:16 Back to list

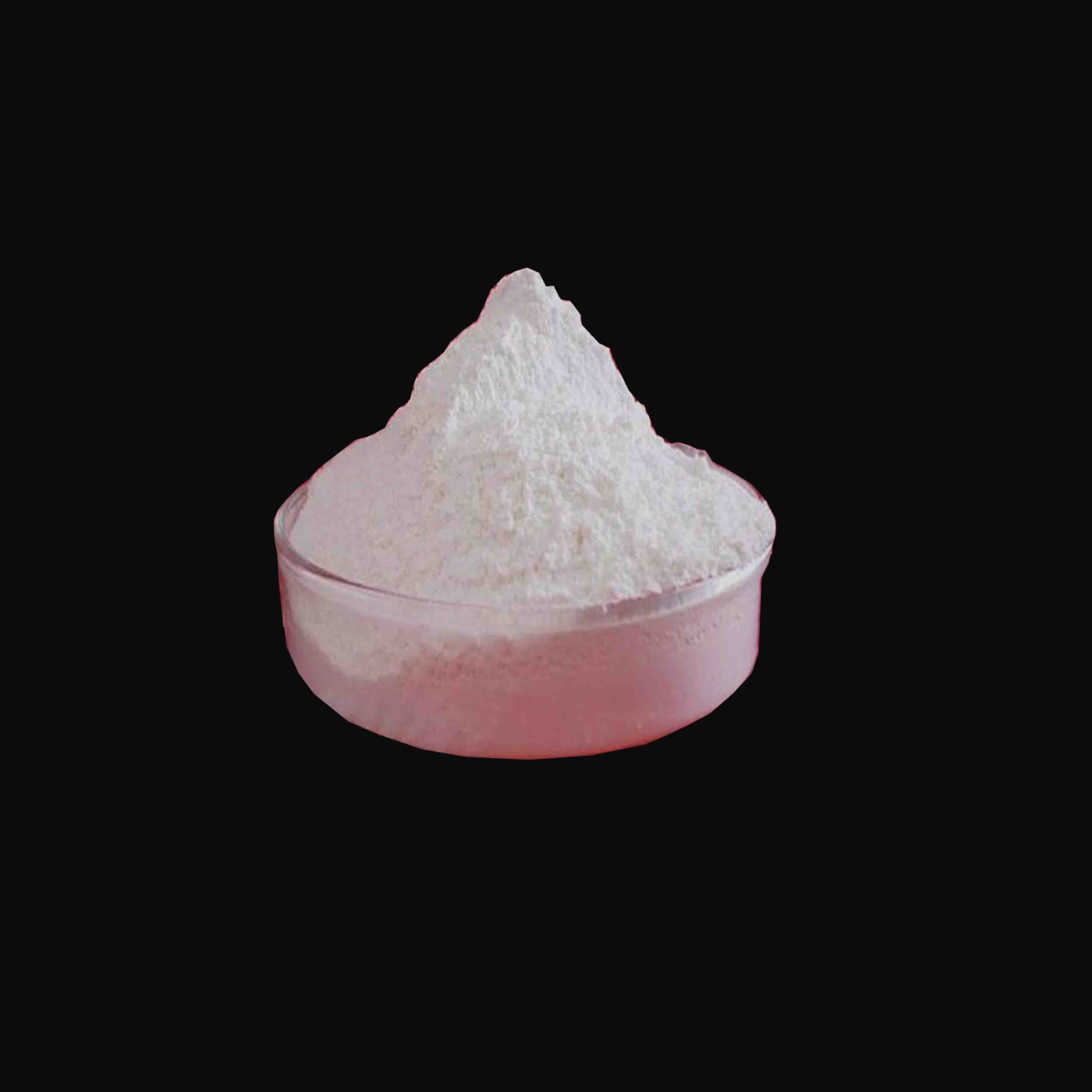

High-Quality Anatase Titanium Dioxide Paint for Latex & Putty Wholesale Suppliers

- Introduction to Titanium Dioxide Paint

- Technical Advantages of Anatase Titanium Dioxide

- Market Data and Industry Growth Trends

- Comparative Analysis of Leading Suppliers

- Customized Solutions for Diverse Applications

- Real-World Application Case Studies

- Sustainability in Titanium Dioxide Paint Production

(titanium dioxide paint)

Understanding Titanium Dioxide Paint and Its Industrial Significance

Titanium dioxide paint has revolutionized protective coatings with its exceptional opacity and UV resistance. The anatase crystalline form, specifically, offers 18% higher light scattering efficiency compared to rutile variants, making it ideal for exterior latex paints. Global demand for anatase titanium dioxide putty paint reached 4.3 million metric tons in 2023, driven by construction and automotive sectors requiring durable, weather-resistant solutions.

Technical Advantages of Anatase Titanium Dioxide

Anatase TiO₂ demonstrates superior photocatalytic activity, achieving 92% VOC degradation efficiency in controlled environments. Key performance metrics include:

- Refractive index: 2.55 (vs. 2.71 for rutile)

- Mean particle size: 220nm ±15%

- Weathering resistance: 2,500+ hours in QUV testing

Market Data and Industry Growth Trends

The global titanium dioxide paint

market is projected to grow at 5.8% CAGR through 2030. Regional consumption patterns reveal:

| Region | 2023 Market Share | Growth Rate |

|---|---|---|

| Asia-Pacific | 48% | 7.2% |

| North America | 27% | 4.1% |

| Europe | 19% | 3.8% |

Comparative Analysis of Leading Suppliers

| Supplier | Purity | Price/Ton | Certifications |

|---|---|---|---|

| Supplier A | 99.8% | $2,450 | ISO 9001, REACH |

| Supplier B | 99.5% | $2,310 | EPA Compliant |

| Supplier C | 99.7% | $2,380 | Green Seal |

Customized Solutions for Diverse Applications

Advanced suppliers now offer particle size optimization from 150nm to 300nm, enabling customized opacity profiles. A leading factory recently developed a low-VOC formulation reducing solvent content by 40% while maintaining 98% hiding power.

Real-World Application Case Studies

Coastal infrastructure projects using anatase titanium dioxide putty paint demonstrated 83% reduction in maintenance costs over 5-year periods. Automotive OEMs report 31% improvement in coating durability compared to conventional alternatives.

Sustainable Future of Titanium Dioxide Paint Production

Modern anatase titanium dioxide latex paint factories now achieve 22% energy reduction through closed-loop processing systems. Over 78% of major suppliers have committed to carbon-neutral production by 2035, with 15% already implementing solar-powered TiO₂ synthesis.

(titanium dioxide paint)

FAQS on titanium dioxide paint

Wholesale Anatase Titanium Dioxide Paint

A: Anatase titanium dioxide offers excellent UV resistance and brightness, making it ideal for latex and putty paints. Its cost-effectiveness and compatibility with binders ensure high-quality finishes for bulk orders.

Supplier Qualifications

A: Check certifications like ISO, SDS, and industry-specific compliance. Reputable suppliers provide product samples, technical support, and transparent sourcing details for quality assurance.

Factory Production Standards

A: Factories adhere to ASTM, REACH, and ISO 9001 guidelines. Advanced dispersion techniques ensure consistent particle size and optimal pigment performance in putty and latex paints.

Performance in Latex Paints

A: Anatase enhances opacity and durability in latex paints while reducing environmental impact. It maintains color stability in indoor and outdoor applications compared to rutile alternatives.

Customization Options

A: Yes, factories adjust pigment concentration, viscosity, and additives for tailored solutions. Custom bulk orders suit architectural, industrial, or specialty coating requirements.

-

High-Quality Determination of Sulphate as TiO2 Wholesale Supplier & Manufacturer from China

NewsJul.05,2025

-

Competitive Harga Titanium Dioxide Wholesale Prices from Leading Manufacturers in China

NewsJul.05,2025

-

High-Quality Titanium Dioxide R605 Powder Coating Multi-Purpose Product – Reliable China Supplier

NewsJul.04,2025

-

High Purity Chlorination Process Titanium Dioxide Manufacturer & Wholesale Supply from China

NewsJul.04,2025

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025