dec. . 01, 2024 07:57 Back to list

Rutile Titanium Dioxide Coating Production Facility for MBR9668 Applications

The Advancements and Applications of Rutile Titanium Dioxide Coatings in Manufacturing

Rutile titanium dioxide (TiO2), particularly in its MBR9668 formulation, has emerged as a significant player in the coating industry due to its exceptional properties and versatility. This white pigment is renowned for its superior brightness, high refractive index, and excellent UV resistance, making it a preferred choice for various applications in coatings, plastics, and other materials. This article explores the advancements in rutile titanium dioxide coatings, particularly focusing on the MBR9668 variant, and its implications for manufacturing.

Understanding Rutile Titanium Dioxide

Titanium dioxide is primarily classified into two crystal structures anatase and rutile. While both forms have their applications, rutile titanium dioxide is favored for its stability and superior optical properties. The MBR9668 composition, specifically engineered for coating applications, boasts enhanced durability and ease of dispersion in various mediums. This makes it ideal for a wide range of products, from paints and varnishes to plastics and construction materials.

Key Properties of MBR9668 Coatings

The MBR9668 variant of rutile titanium dioxide offers several noteworthy properties

1. UV Resistance One of the key benefits of rutile TiO2 is its ability to reflect harmful ultraviolet (UV) rays. Coatings that incorporate MBR9668 are highly effective in preventing degradation of substrates, increasing the longevity of the applied surfaces.

2. High Pigment Quality The unique formulation of MBR9668 enhances the pigment's opacity and brightness. This high-quality finish not only improves aesthetic appeal but also maximizes the hiding power, reducing the amount of pigment required in formulations.

4. Adhesion Properties The MBR9668 coating enhances adhesion to a wide array of substrates, ensuring that the coatings do not peel or flake over time. This is particularly crucial in industrial applications where the longevity of the coating can significantly impact operational costs.

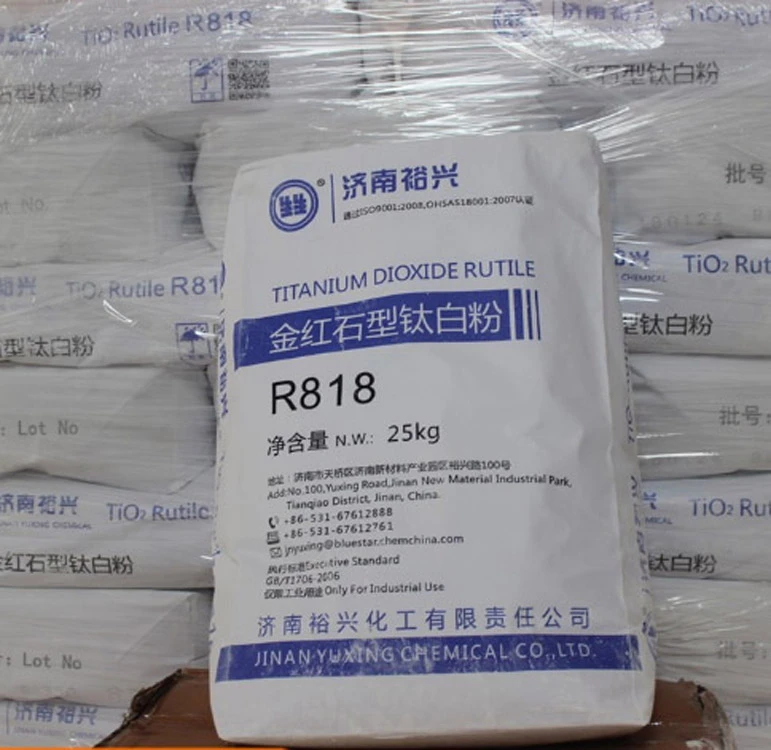

rutile titanium dioxide mbr9668-coating factory

Applications in Manufacturing

The versatility of MBR9668 rutile titanium dioxide coatings opens doors to numerous applications across various industries

1. Architectural Coatings In the construction industry, MBR9668 is used in exterior paints and coatings, where UV resistance and durability are crucial. It helps in providing long-lasting finishes that stand up against weathering and environmental factors.

2. Automotive Coatings The automotive sector benefits from the use of MBR9668 due to its excellent color retention and the ability to withstand harsh conditions. It is commonly used in primers and topcoats to ensure vehicles maintain their visual appeal while protecting surfaces.

3. Plastics In plastic manufacturing, MBR9668 is utilized to create vibrant, UV-stable products, making it ideal for consumer goods, outdoor furniture, and toys. The effective incorporation of this pigment enhances both performance and aesthetics.

4. Industrial Coatings For machinery and equipment exposed to heavy wear and tear, MBR9668 rutile titanium dioxide coatings provide an extra layer of protection against corrosion and abrasion, extending the life cycle of industrial assets.

Environmental Considerations

While there is a growing demand for rutile titanium dioxide coatings, manufacturers are also focused on sustainability. The production processes for MBR9668 are increasingly being streamlined to reduce environmental impact, including minimizing waste and energy consumption. Moreover, the long-lasting qualities of these coatings contribute to more environmentally sustainable products by reducing the need for frequent reapplication and disposal.

Conclusion

Rutile titanium dioxide, particularly in the form of MBR9668, represents a significant advancement in coating technologies. Its unique properties and broad applications make it a vital component in numerous industries. As the demand for high-performance coatings continues to grow, innovations surrounding rutile TiO2 will play a crucial role in shaping the future of manufacturing and sustainability in coating solutions. With its excellent durability, aesthetic appeal, and environmental advantages, MBR9668 is set to remain at the forefront of coating technologies for years to come.

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025