nov. . 27, 2024 15:13 Back to list

Rutile TiO2 Suppliers and Manufacturers for High-Performance Applications

The Global Landscape of Rutile TiO2 Manufacturers

Rutile titanium dioxide (TiO2) is a white pigment widely recognized for its excellent opacity and brightness, making it an essential component in various industries, including paints, coatings, plastics, and paper. As the demand for high-quality rutile TiO2 continues to rise globally, the manufacturing landscape has evolved significantly. This article explores the current state of rutile TiO2 manufacturers, key market drivers, and future trends.

Understanding Rutile and Its Importance

Rutile is one of the main mineral forms of titanium dioxide and is primarily sourced from titanium-bearing ores such as ilmenite and rutile sand. Unlike the anatase form of TiO2, rutile offers superior qualities that enhance light scattering properties, making it the preferred choice for many applications, especially in the production of premium paints and coatings. The manufacturing of rutile TiO2 involves processes that extract titanium from these ores, refined into a highly pure and stable pigment.

Key Players in the Market

The rutile TiO2 market is characterized by a mix of large multinational corporations and smaller, specialized manufacturers. Some of the leading players include

- Paints and Coatings Manufacturers Companies like Sherwin-Williams and PPG Industries have significant demand for rutile TiO2 due to their extensive product lines. Their ability to innovate and apply advanced formulations in paints makes them key customers of TiO2 producers.

- Industrial Chemical Producers Companies such as Tronox and Chemours are significant producers of rutile TiO2, using advanced technologies and sustainable practices to extract and process titanium. They hold a considerable share of the market, leveraging their capacities to meet growing demand across various sectors.

- Emerging Manufacturers In addition to established giants, several emerging companies are entering the rutile TiO2 market, particularly in regions such as Asia and Africa, where rich mineral deposits are available. These new entrants often focus on cost-effective production methods, capitalizing on lower labor and material costs.

Market Drivers and Demand Dynamics

The demand for rutile TiO2 is primarily driven by several factors

1. Growing Construction Industry With increasing urbanization and infrastructure development, the construction sector is one of the largest consumers of TiO2. The pigment’s properties enhance the durability and aesthetic appeal of materials used in building and construction projects.

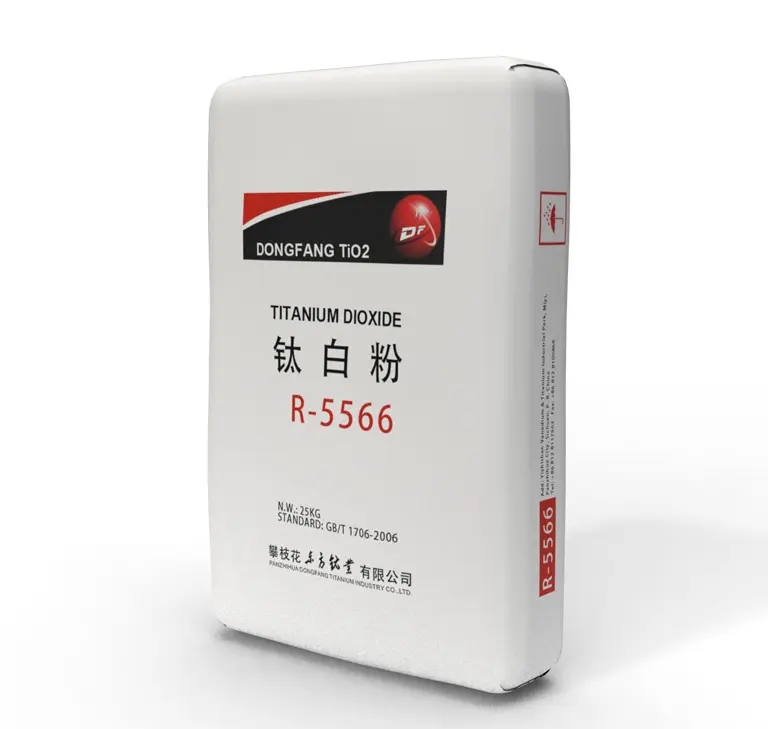

rutile tio2 manufacturer

2. Environmental Regulations The paint and coatings industry is facing stringent environmental regulations, pushing manufacturers to produce eco-friendly products. Rutile TiO2 is considered to be a safer alternative to other pigments and is increasingly favored for its lower environmental impact.

3. Technological Advancements Innovations in manufacturing processes have improved the efficiency of rutile TiO2 production. Techniques such as chloride process technology have emerged, allowing for higher quality output with lower energy consumption.

4. Sustainable Practices The shift toward sustainability is significantly influencing the TiO2 market. Manufacturers are investing in recycling initiatives and exploring alternative sources of titanium, reducing their carbon footprint and aligning with consumer preferences for environmentally friendly products.

Future Trends in Rutile TiO2 Manufacturing

Looking forward, several trends are likely to shape the rutile TiO2 market

- Increased Focus on Sustainability As more industries adopt sustainable practices, manufacturers will need to adapt by developing greener production methods and sourcing practices. This may include using renewable energy sources and reducing waste in the production process.

- Innovation in Applications The versatility of rutile TiO2 is likely to spur innovations in new applications. For instance, its use in high-performance plastics and advanced coatings can create pathways for the material in emerging markets such as electronics and automotive.

- Market Consolidation As competition intensifies, there may be an increase in mergers and acquisitions among TiO2 producers. This could lead to enhanced resources and capabilities to meet global demand effectively.

- Geopolitical Factors Supply chain disruptions stemming from geopolitical tensions and trade policies can impact the availability and pricing of rutile TiO2. Manufacturers must navigate these challenges to ensure a steady flow of materials.

Conclusion

The rutile TiO2 manufacturing industry stands at a crossroads of growth and innovation, driven by evolving market demands and the imperative for sustainability. As leading manufacturers adapt to these changes, the focus will increasingly shift towards producing high-quality, environmentally friendly products that cater to a broad spectrum of applications. Embracing innovation and sustainability will be crucial for maintaining a competitive edge in this vibrant market.

-

13463-67-7 Titanium Dioxide Using for Coating Supplier – High-Quality Rutile TiO2 for Paints

NewsJul.26,2025

-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025