dec. . 09, 2024 17:21 Back to list

Lithopone Pigment Production and Applications in Various Industries

The Evolution and Significance of Lithopone Pigment Factories

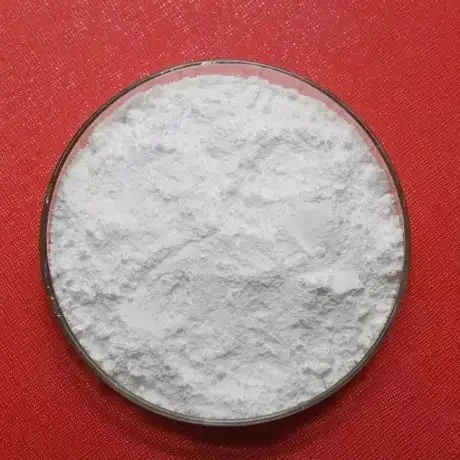

Lithopone, a white pigment composed of a mixture of barium sulfate and zinc sulfide, has been a cornerstone in various industries, particularly in paints, coatings, and plastics. The development and production of lithopone pigments have a rich history that reflects advancements in technology, shifts in consumer preferences, and the growing demand for environmentally friendly products. This article explores the evolution of lithopone pigment factories, their significance in modern manufacturing, and the challenges they face in a rapidly changing market.

Historical Background

Lithopone was first discovered in the late 19th century as a more affordable and non-toxic alternative to lead white pigments, which had been widely used but posed significant health risks. By the early 20th century, lithopone pigments began to gain traction in various applications due to their excellent opacity, high hiding power, and durability. Initially, production was labor-intensive, relying heavily on manual processes to achieve the desired purity and consistency.

With the advent of industrialization, lithopone pigment factories began to emerge, particularly in Europe and North America. These factories adopted new technologies, such as chemical synthesis and advanced milling techniques, to improve production efficiency. The development of modern milling and blending equipment allowed for the mass production of lithopone, making it more widely available and cost-effective.

Manufacturing Process

The production of lithopone involves a series of chemical reactions and processes. It begins with the combination of barium sulfide and zinc sulfate in a controlled environment, resulting in the precipitation of barium zinc sulfide. This compound is then washed, dried, and milled to achieve the desired particle size and distribution. The quality of lithopone is determined by its purity and the ratio of its components, which can vary based on end-use applications.

Factories specializing in lithopone pigments must adhere to strict environmental and safety regulations. As consumer awareness about sustainability and safety increases, modern lithopone manufacturers have implemented eco-friendly practices to minimize waste and reduce emissions. Many factories now incorporate closed-loop systems and recycling processes to ensure that their operations are sustainable and compliant with global standards.

lithopone pigments factory

Applications and Market Demand

Lithopone pigments are widely used across multiple sectors. In the paint and coatings industry, they provide excellent coverage and brightness, making them ideal for exterior and interior applications. Their high thermal stability and resistance to yellowing make them suitable for high-performance paints. Additionally, lithopone finds applications in plastics, inks, and rubber, where its non-toxicity and durability are highly valued.

The market demand for lithopone pigments continues to grow, driven by the increasing need for environmentally friendly and safe products. Industries are increasingly seeking alternatives to conventional pigments that may contain harmful substances, such as heavy metals. Lithopone stands out for its non-toxic properties, making it a preferred choice for manufacturers aiming to comply with stringent regulatory standards.

Challenges in the Industry

Despite the positive outlook for lithopone pigment factories, the industry faces several challenges. One significant concern is competition from alternative pigments, such as titanium dioxide, which offers superior opacity and brightness. Though higher in cost, titanium dioxide has gained popularity due to its performance characteristics. Lithopone manufacturers must find ways to differentiate their products and demonstrate the unique benefits of lithopone in various applications.

Moreover, fluctuating raw material prices pose a challenge to production costs. As the demand for barium and zinc continues to rise, lithopone manufacturers must navigate the complexities of sourcing materials while maintaining competitive pricing.

Conclusion

In conclusion, lithopone pigment factories play a crucial role in the modern manufacturing landscape, providing high-quality pigments that meet the demands of various industries. As technology advances and consumer preferences shift towards sustainable products, these factories must adapt to ensure their relevance and competitiveness. By embracing innovation and focusing on eco-friendly practices, lithopone manufacturers can continue to thrive in a dynamic market, contributing to a safer and greener future.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025