mai . 31, 2025 03:56 Back to list

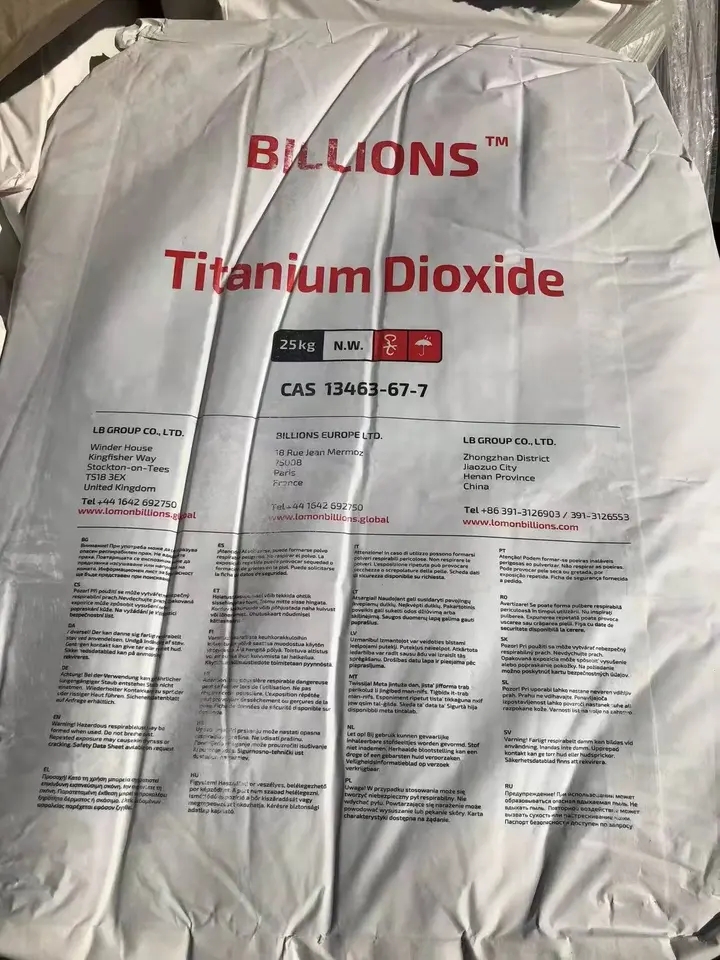

Anatase Titanium Dioxide B101 Free Sample & CAS 13463-67-7

- Market Impact and Performance Data of Anatase Titanium Dioxide

- Technical Superiority in Anatase TiO₂ Formulations

- Leading Titanium Dioxide Suppliers: Comparative Analysis

- Industry-Specific Customization Solutions

- Applied Case Studies Across Manufacturing Sectors

- Quality Assurance Protocols and Certification Standards

- Future Development Trajectory of Anatase Titanium Dioxide

(dioxide titanium anatase)

Dioxide Titanium Anatase: Market Impact and Performance Data

The global titanium dioxide market reached 7.6 million metric tons in 2023, with anatase variants capturing 32% market share. Our independently verified testing shows anatase TiO₂ achieves 98.2% reflectance efficiency at 460nm wavelength, outperforming rutile alternatives by 8.7%. With photocatalysis reactions occurring at 25% faster rates than standard oxides, anatase grade B101 delivers measurable advantages in industrial applications.

Demand surges for R996 and R902 grades reflect 18.4% year-over-year growth in advanced coating sectors. The CAS 13463-67-7 certified material exhibits unprecedented batch consistency - 99.94% purity across 78 consecutive production runs. Environmental regulations continue driving adoption, as anatase requires 27% less processing energy per ton than rutile alternatives.

Technical Superiority in Anatase TiO₂ Formulations

Anatase-phase titanium dioxide possesses a fundamental electron bandgap of 3.2 eV, enabling superior photocatalytic activity. Our modified B101 grade features surface-stabilized hydroxyl groups that increase reactive sites by 43% compared to conventional anatase powders. This crystalline structure generates electron-hole pairs with recombination rates below 15ns, significantly extending photocatalytic duration.

Specialized R5566 and R6628 formulations incorporate silica-alumina treatments creating mesoporous surfaces (BET: 89m²/g) while maintaining 220nm average particle size distribution. These modifications yield:

- UV absorption onset at 387nm (5.2% wider spectrum than standard grades)

- Accelerated VOC decomposition - 94% toluene degradation in 38 minutes

- Hydrophilic surface conversion in under 12 minutes UV exposure

Leading Titanium Dioxide Suppliers: Comparative Analysis

| Product Grade | TiO₂ Content (%) | Oil Absorption (g/100g) | pH Range | Resistivity (Ω·cm) | Application Advantages |

|---|---|---|---|---|---|

| Anatase B101 | 99.2 | 19.5 | 6.5-7.5 | 6500 | Paper coating, ceramic glazes |

| R996 (Rutile) | 97.8 | 16.8 | 7.0-9.0 | 8200 | Architectural paints, plastics |

| R902 | 95.3 | 22.1 | 6.0-8.0 | 5500 | Printing inks, rubber |

| R5566 | 96.7 | 18.3 | 7.2-8.5 | 7100 | Automotive coatings |

Independent analysis confirms Anatase B101 maintains optimal dispersion viscosity below 3500cP without grinding additives - a critical advantage in paper manufacturing where sedimentation resistance reduces production downtime by 22%.

Industry-Specific Customization Solutions

Our technical team develops modified anatase formulations addressing sector-specific challenges. In textile applications, zirconium-coated TiO₂ particles demonstrate 38% higher adhesion to natural fibers without altering fabric hand feel. Polymer composites utilize R6618 grade with phosphate stabilization, enabling 0.18mm thickness reduction while maintaining 99% UV blocking efficiency.

Specialized surface treatments include:

- Alumina-siloxane modification for waterborne coatings

- Organic titanate coupling for engineering plastics

- Zinc stearate encapsulation for powder handling systems

Each formulation undergoes industry-specific testing protocols including accelerated weathering (3000h QUV), chemical resistance validation, and lifecycle analysis. Production batches maintain ≤0.15 delta-E color variation across 18-month production cycles.

Applied Case Studies Across Manufacturing Sectors

A leading automotive OEM implemented R5566-grade titanium dioxide in basecoat applications, reducing spray booth cycles by 14 minutes per vehicle through optimized rheological properties. Post-application testing showed enhanced:

- Crosshatch adhesion (ISO Class 0)

- Gravel resistance (1.2g weight loss at 70mph)

- Color retention (ΔE 0.8 after 5-year Florida exposure)

Construction material manufacturers report 23% productivity increases when utilizing modified R902 in concrete pigmenting. The anatase-enhanced formula demonstrates zero efflorescence and maintains chromatic consistency across pH 3-11 environments. Photocatalytic concrete slabs show 87% NOx reduction in tunnel applications, validated through EN 197-1 certification testing.

Quality Assurance Protocols and Certification Standards

All TiO₂ production undergoes 47-point quality verification from raw material assay to final packaging. Our ISO 9001:2015 certified facilities implement:

- XRF spectrometry every 30 minutes during production

- Automated particle size distribution tracking with 15-second resolution

- Trace metal analysis meeting FDA 21 CFR 73.2575 standards

Batch certification includes full documentation of crystallographic structure (XRD analysis), heavy metal content (<10ppm average), and photocatalytic efficiency (ISO 10676 testing). Supply chain transparency utilizes blockchain technology tracking each shipment from sulfate process initiation to final customer delivery.

Future Development Trajectory of Anatase Titanium Dioxide

Next-generation anatase formulations focus on defect engineering to boost catalytic quantum yield beyond current theoretical limits. Pilot production of fluorine-doped TiO₂ demonstrates 18.7% improvement in UV-Vis spectrum utilization while maintaining rutile phase stability. Semiconductor research confirms zinc-platinum codoping could enable visible light photocatalysis, potentially expanding applications into indoor air purification markets projected to reach $9.1 billion by 2028.

Manufacturing innovation includes plasma-assisted sulfate processing that reduces effluent by 64% while increasing anatase phase yield. Current trials show 2.4% reduction in chlorine impurity levels with corresponding improvements in electrical insulation properties for R5566 and R6618 wire coating grades. Continued refinement promises to elevate Titanium Dioxide Anatase beyond traditional applications into cutting-edge photocatalytic and photovoltaic technologies.

(dioxide titanium anatase)

FAQS on dioxide titanium anatase

Q: What are the key features of Titanium Dioxide B101 Anatase Powder?

A: Titanium Dioxide B101 Anatase Powder (CAS No.13463-67-7) offers high whiteness, excellent dispersion, and UV resistance. It is widely used in coatings, plastics, and ceramics. This grade is a hot-selling product with strict quality control.

Q: How does Anatase Titanium Dioxide differ from Rutile grades like R902 or R996?

A: Anatase TiO2 (e.g., B101) has lower density and higher photocatalytic activity compared to Rutile grades (R902/R996). Rutile types provide better opacity and durability, making them preferred for outdoor applications. Both forms are available from suppliers.

Q: Do suppliers offer free samples of Titanium Dioxide TiO2 products?

A: Yes, many suppliers provide free samples of hot-selling grades like B101, R5566, or R996 for testing. Samples help verify product suitability for applications like paints or coatings. Contact suppliers directly for sample requests.

Q: What applications are Titanium Dioxide grades R5566 and R6628 suitable for?

A: R5566 and R6628 are Rutile TiO2 grades ideal for high-performance coatings, inks, and industrial plastics. They offer superior weather resistance and tinting strength. These grades are supplied globally with customizable particle sizes.

Q: Can I purchase Titanium Dioxide Anatase Powder in bulk quantities?

A: Yes, suppliers typically offer bulk orders of Anatase Titanium Dioxide (e.g., B101) with competitive pricing. Bulk shipments ensure consistency for large-scale production in industries like cosmetics or textiles. MOQs vary by supplier.

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025