titania tio2 factory

Fev . 15, 2025 14:35 Back to list

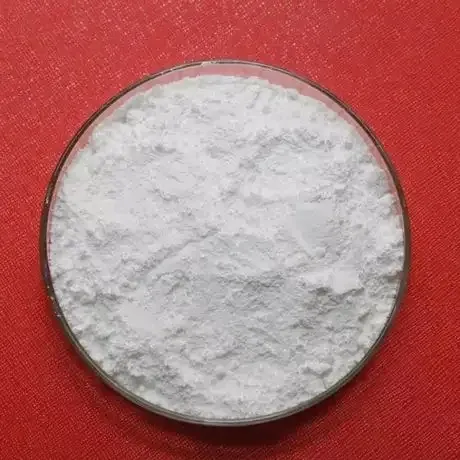

titania tio2 factory

The role of titanium dioxide (TiO2) in water treatment facilities is gaining increased attention as industries seek sustainable and efficient solutions for ensuring safe water. With its unique photocatalytic properties, TiO2 has demonstrated significant potential to revolutionize water purification processes.

Despite its benefits, the deployment of TiO2 in water factories is not without challenges. The initial setup costs can be high, as it involves specialized coatings and UV light systems. However, plant operators who have adopted this technology emphasize the long-term financial advantages, including lower maintenance costs and compliance with stringent water quality regulations. Expert voices in the field consistently endorse the use of TiO2, citing its high efficacy rates and dual functionality. Not only does it purify water, but it also elevates the operational efficiency of treatment plants. Publications in reputable journals further validate these claims, providing scientific backing to an otherwise innovative approach. Trust in TiO2 as a reliable component of water treatment has been bolstered by widespread academic and governmental studies. Institutions conducting pilot programs have reported successful outcomes, leading to broader acceptance and policy support. This increasing body of evidence contributes to confidence among industry leaders and governments. The deployment of TiO2 in water treatment is not just a trend but a forward-thinking solution that integrates scientific understanding with real-world applications. As awareness and technological developments continue to grow, TiO2 stands poised to become a cornerstone of modern water treatment strategies globally. Its potential to deliver clean, safe, and sustainable water makes it not only an advanced technological choice but also an ethical one.

Despite its benefits, the deployment of TiO2 in water factories is not without challenges. The initial setup costs can be high, as it involves specialized coatings and UV light systems. However, plant operators who have adopted this technology emphasize the long-term financial advantages, including lower maintenance costs and compliance with stringent water quality regulations. Expert voices in the field consistently endorse the use of TiO2, citing its high efficacy rates and dual functionality. Not only does it purify water, but it also elevates the operational efficiency of treatment plants. Publications in reputable journals further validate these claims, providing scientific backing to an otherwise innovative approach. Trust in TiO2 as a reliable component of water treatment has been bolstered by widespread academic and governmental studies. Institutions conducting pilot programs have reported successful outcomes, leading to broader acceptance and policy support. This increasing body of evidence contributes to confidence among industry leaders and governments. The deployment of TiO2 in water treatment is not just a trend but a forward-thinking solution that integrates scientific understanding with real-world applications. As awareness and technological developments continue to grow, TiO2 stands poised to become a cornerstone of modern water treatment strategies globally. Its potential to deliver clean, safe, and sustainable water makes it not only an advanced technological choice but also an ethical one.

Next:

Latest news

-

Premium Titania TiO2 Manufacturer & Supplier

NewsAug.08,2025

-

Wholesale Titania TiO2 | Factory Direct Suppliers & Manufacturers

NewsAug.07,2025

-

R996 TiO2: High Performance Rutile Titanium Dioxide

NewsAug.06,2025

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025