Nov . 06, 2024 12:04 Back to list

ISk Tio2 Supplier for High-Quality Titanium Dioxide Products and Solutions

ISK TiO2 Manufacturer Leading the Innovation in Titanium Dioxide Production

In the ever-evolving landscape of materials science, titanium dioxide (TiO2) has emerged as a critical component across various industries, including paints, plastics, cosmetics, and food. Among the notable players in this field is ISK, a manufacturer renowned for its commitment to quality, innovation, and sustainability in the production of titanium dioxide.

Understanding Titanium Dioxide

Titanium dioxide is a white inorganic pigment that is celebrated for its excellent covering power, brightness, and durability. It is often used to enhance the opacity and brightness of products, making it highly desirable in applications such as coatings, inks, and plastics. The compound is derived from titanium ore and comes primarily in two crystalline forms anatase and rutile. While both forms have their unique properties, rutile is favored for most applications due to its superior optical properties.

ISK's Commitment to Quality

ISK has established itself as a trusted titanium dioxide manufacturer by emphasizing quality in every aspect of its operations. Their production processes comply with stringent international standards, ensuring that the TiO2 produced is consistent and reliable. Incorporating state-of-the-art technology and advanced manufacturing processes, ISK is capable of producing TiO2 that meets the diverse needs of its clientele while maintaining high standards of excellence.

Innovation at the Core

Innovation is at the heart of ISK’s operations. The company invests significantly in research and development to explore new methods and applications for titanium dioxide. By collaborating with industry stakeholders and academic institutions, ISK is continually pushing the boundaries of what TiO2 can achieve. For instance, the company is actively exploring alternative processing techniques that could enhance the efficiency and sustainability of titanium dioxide production.

Sustainable Practices

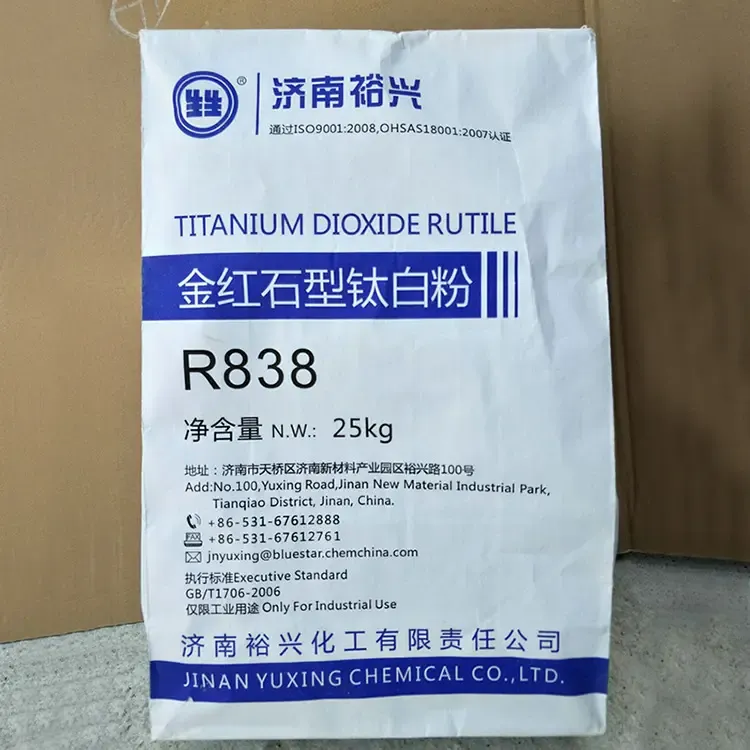

isk tio2 manufacturer

In recent years, sustainability has become a focal point for manufacturers across the globe. ISK is no exception, as it integrates eco-friendly practices into its production methods. The company is committed to minimizing its environmental footprint by employing energy-efficient processes and reducing waste. ISK also prioritizes sourcing raw materials responsibly, ensuring that its supply chain aligns with sustainable principles.

Meeting Market Demands

The global demand for titanium dioxide is projected to grow steadily, driven by the expansion of various industries such as construction, automotive, and consumer goods. ISK positions itself strategically to meet this growing demand by enhancing its production capacity and product offerings. By developing specialized TiO2 products tailored for specific applications, ISK can cater to the unique needs of its customers across different sectors.

Customer-Centric Approach

One of the key differentiators for ISK is its customer-centric approach. The company places significant emphasis on understanding the individual needs of its clients and providing tailored solutions. By maintaining open lines of communication and fostering strong relationships, ISK ensures customer satisfaction and loyalty.

Global Reach

With a robust distribution network, ISK is well-equipped to serve a global clientele. The company exports its titanium dioxide products to various countries, thereby contributing to the global supply chain. This international presence allows ISK to stay attuned to market trends and customer preferences worldwide, further enhancing its competitive edge.

Conclusion

ISK stands out as a forward-thinking manufacturer in the titanium dioxide industry. With a strong focus on quality, innovation, sustainability, and customer satisfaction, ISK is well-positioned to lead the way in providing high-quality TiO2 solutions. As industries continue to evolve, ISK’s commitment to excellence ensures that it remains a pivotal player in the market for years to come. In an era where the demand for sustainable practices is increasing, ISK's proactive approach will keep it at the forefront of the titanium dioxide manufacturing sector.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025