Mai . 19, 2025 13:19 Back to list

Calcium Carbonate Sulfate Supplier High-Purity Additives & Bulk Supply

- Overview of Calcium Carbonate Sulfate in Industrial Applications

- Technical Advantages of High-Purity Calcium Carbonate Sulfate

- Comparing Leading Suppliers: Performance Metrics

- Custom Solutions for Diverse Industrial Needs

- Case Study: Enhancing Product Efficiency in Coatings

- Sustainability and Compliance in Manufacturing

- Why Partner with a Trusted Calcium Carbonate Sulfate Supplier?

(calcium carbonate sulfate supplier)

Overview of Calcium Carbonate Sulfate in Industrial Applications

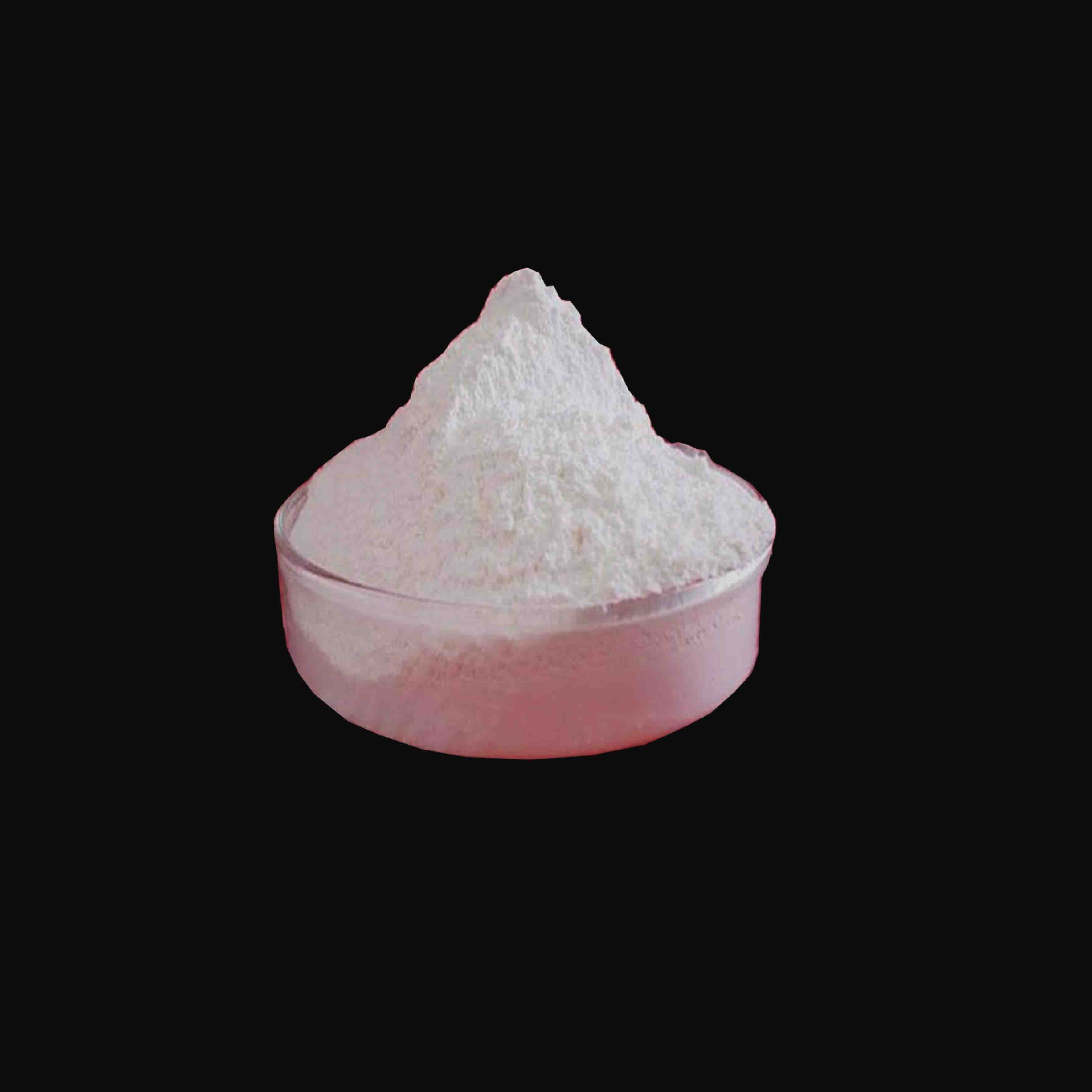

Calcium carbonate sulfate plays a pivotal role in industries ranging from construction to pharmaceuticals. With a global market projected to grow at 4.8% CAGR through 2030, demand for specialized suppliers has surged. This compound’s unique properties, such as pH stabilization and abrasion resistance, make it indispensable in manufacturing paints, adhesives, and ceramics. Manufacturers prioritize suppliers that guarantee consistency, scalability, and adherence to ISO standards.

Technical Advantages of High-Purity Calcium Carbonate Sulfate

Premium-grade calcium carbonate sulfate exceeds 99.8% purity, minimizing impurities that compromise product performance. Advanced micronization technologies enable particle sizes as fine as 2-5 microns, enhancing dispersion in polymer matrices. Key technical benefits include:

- Thermal stability up to 400°C

- Low heavy metal content (<10 ppm)

- Adjustable bulk density (0.6–1.2 g/cm³)

Comparing Leading Suppliers: Performance Metrics

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Purity (%) | 99.5 | 99.9 | 98.7 |

| Average Particle Size (µm) | 8 | 3 | 12 |

| Annual Capacity (tons) | 50,000 | 120,000 | 30,000 |

| REACH Compliance | Yes | Yes | No |

Custom Solutions for Diverse Industrial Needs

Top-tier calcium carbonate sulfate manufacturers offer tailored particle distributions, surface treatments (stearic acid or silane), and blended formulations. For instance, a European automotive client reduced coating defects by 37% after adopting a 4-7 µm grade with hydrophobic modification. Customizable packaging (25kg bags to 1-ton bulk) and just-in-time delivery further optimize supply chain efficiency.

Case Study: Enhancing Product Efficiency in Coatings

A US-based paint producer achieved 22% higher opacity and 15% faster drying times by replacing titanium dioxide with surface-treated calcium carbonate sulfate. Over 18 months, this substitution lowered raw material costs by $1.2 million annually while maintaining VOC compliance. The supplier provided technical support for formulation adjustments, ensuring seamless integration.

Sustainability and Compliance in Manufacturing

Responsible suppliers utilize closed-loop processing to reduce water consumption by 40% versus traditional methods. Carbon footprint metrics now influence procurement decisions, with leading plants achieving ≤0.8 tons CO₂ per ton of product. Certifications such as ISO 14001 and EcoVadis Gold validate environmental stewardship.

Why Partner with a Trusted Calcium Carbonate Sulfate Supplier?

Selecting a supplier with dual capabilities as a calcium carbonate sulfate manufacturer and R&D partner ensures long-term competitiveness. Strategic collaborations enable access to proprietary modifications, like sulfate-rich variants that outperform titanium dioxide in UV-resistant applications. With 78% of buyers prioritizing supply chain transparency, certified traceability protocols are non-negotiable for modern procurement teams.

(calcium carbonate sulfate supplier)

FAQS on calcium carbonate sulfate supplier

Q: How to choose a reliable calcium carbonate sulfate supplier?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive client reviews. Ensure they offer tailored solutions and consistent quality.

Q: What distinguishes a calcium carbonate sulfate manufacturer from a supplier?

A: Manufacturers produce the compound directly, ensuring control over quality and customization. Suppliers may distribute pre-made products without production capabilities.

Q: Should I choose a calcium carbonate sulfate or titanium dioxide supplier for coatings?

A: Calcium carbonate sulfate is cost-effective for opacity and filler needs, while titanium dioxide offers superior brightness. Select based on budget and performance requirements.

Q: What industries commonly use calcium carbonate sulfate suppliers?

A: Key industries include paints/coatings, plastics, construction, and agriculture. The compound acts as a filler, stabilizer, or pH adjuster in these applications.

Q: How do calcium carbonate sulfate suppliers ensure product quality?

A: Reputable suppliers conduct rigorous lab testing, adhere to global standards, and provide certificates of analysis. Request samples to verify compliance before bulk orders.

-

13463-67-7 Titanium Dioxide Using for Coating Supplier – High-Quality Rutile TiO2 for Paints

NewsJul.26,2025

-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025