Nov . 09, 2024 00:07 Back to list

Lithopone B301 28% Suppliers for ZNS and BASO4 Products

The Significance and Manufacturing of Lithopone B301 28% in the Pigment Industry

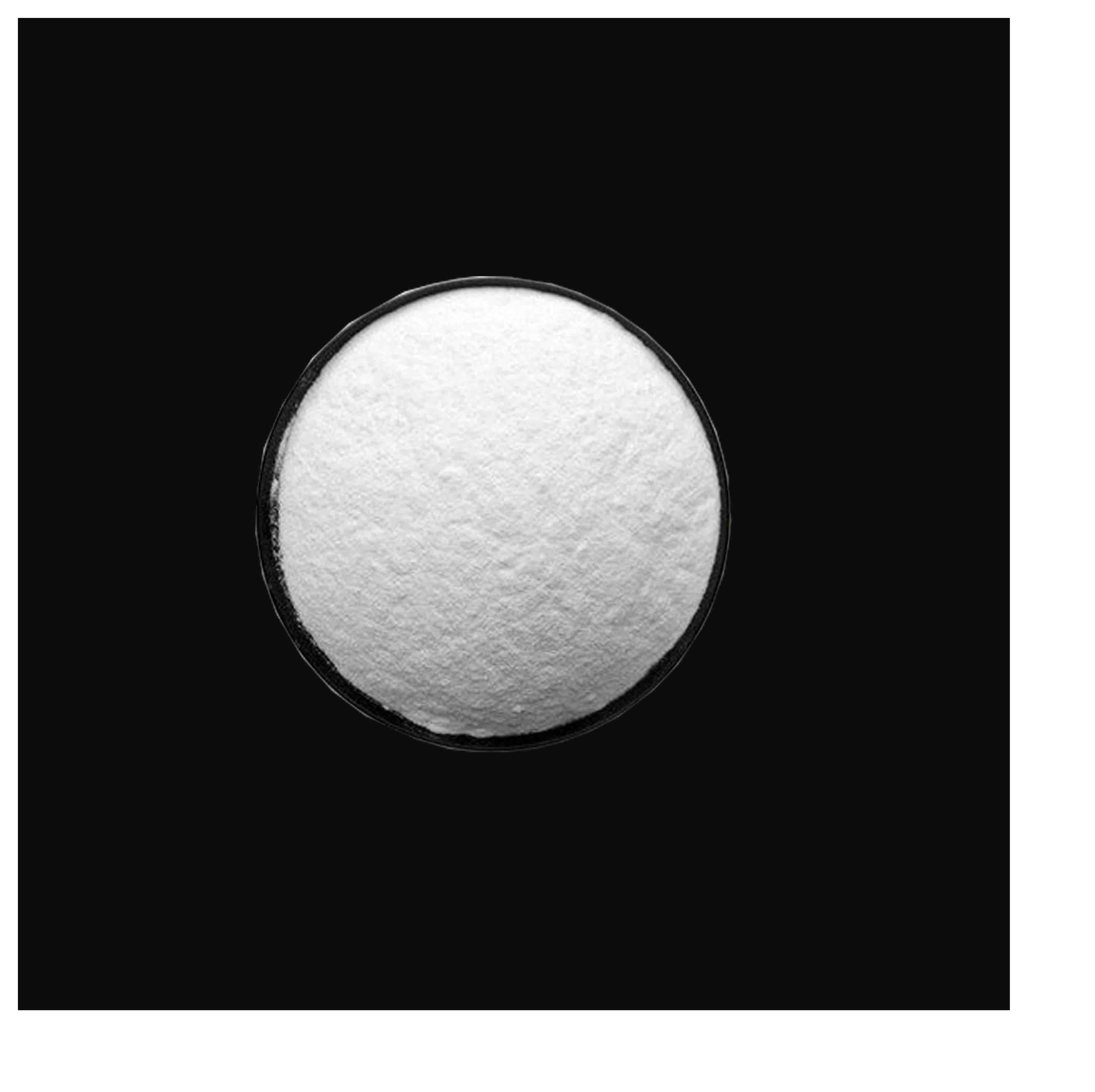

Lithopone, a white pigment containing a mixture of zinc sulfide and barium sulfate, has played an essential role in various applications throughout the paint, plastics, and paper industries. Among the diverse grades of lithopone available, Lithopone B301 28% stands out for its exceptional properties and versatility. Understanding the manufacturing process and significance of this pigment is crucial for both producers and end-users in the pigment market.

What is Lithopone?

Lithopone is known for its excellent whiteness, lightfastness, and high hiding power. Composed primarily of barium sulfate (BaSO4) and zinc sulfide (ZnS), it is often favored as a pigment for its non-toxic nature compared to other white pigments like titanium dioxide. Lithopone is particularly suitable for applications where environmental and health safety is a concern.

The Composition of Lithopone B301 28%

Lithopone B301 28% refers to a specific grade of lithopone that contains approximately 28% zinc sulfide and a base of barium sulfate. This blend provides a unique balance of brightness and opacity, making it an ideal choice for various applications, particularly in coatings and plastics. Its excellent performance in terms of durability and dispersion rates makes it an essential ingredient in formulations aimed at improving aesthetics and longevity.

Manufacturing Process

The production of Lithopone B301 28% involves a multi-step process that begins with the careful selection and preparation of raw materials, primarily zinc and barium compounds. The process typically includes

znsbaso4 lithopone b301 28% manufacturers

1. Precipitation The raw materials are mixed under controlled conditions to initiate a chemical reaction that produces an intermediate compound. 2. Filtration and washing Once the desired precipitate forms, it is filtered and washed several times to remove impurities and unreacted materials, ensuring the purity of the lithopone.

3. Drying The wet product is then dried to obtain a free-flowing powder. This step is critical to achieving the right consistency and moisture content, directly affecting the pigment's performance.

4. Milling After drying, the lithopone is milled to achieve the desired particle size and distribution, which is vital for its application in paints and coatings.

5. Quality Control Testing at various stages ensures that the final product meets specific quality standards, including hue, opacity, and dispersibility.

Applications of Lithopone B301 28%

Lithopone B301 28% finds widespread use across various industries. In the paint and coatings sector, it enhances the finish, opacity, and durability of products. In plastics, its lightfastness and non-toxic nature make it an excellent choice for consumer goods that require safety and aesthetic appeal. Moreover, the paper industry benefits from lithopone's ability to improve brightness and print quality.

Conclusion

The importance of Lithopone B301 28% in the pigment industry cannot be overstated. Its unique properties, combined with a meticulous manufacturing process, ensure that it remains a preferred choice for various applications. With a growing emphasis on safety and environmental sustainability, lithopone continues to be a key player in providing effective solutions in a diverse range of industries. Manufacturers who focus on quality and innovation in the production of lithopone will likely find themselves at the forefront of the market, catering to an ever-increasing demand for high-performance pigments.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025