Dec . 05, 2024 03:47 Back to list

Wholesale Titanium Dioxide for Rubber Applications and Industrial Uses at Competitive Prices

Wholesale Titanium Dioxide for Rubber A Comprehensive Overview

Titanium dioxide, commonly referred to as TiO₂, is one of the most widely used white pigments in various industries, including paints, coatings, plastics, and rubber. Its exceptional ability to provide brightness and opacity makes it an indispensable component in many manufacturing processes. This article delves into the significance of wholesale titanium dioxide for rubber, highlighting its properties, benefits, sourcing options, and emerging trends in the market.

Understanding Titanium Dioxide

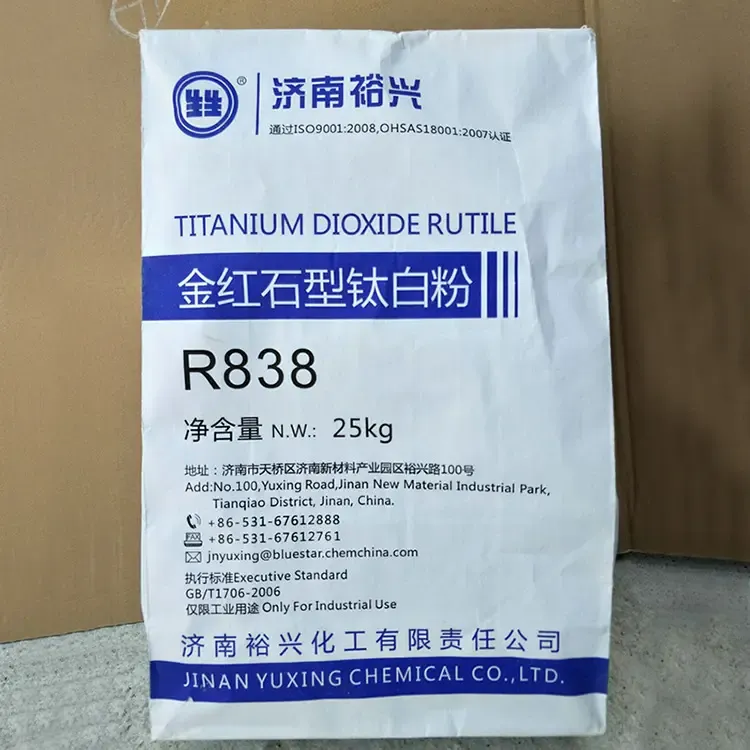

Titanium dioxide exists in three primary crystalline forms rutile, anatase, and brookite. Among these, rutile is the most commonly used in industrial applications due to its superior pigmentation properties and greater stability. The material is non-toxic, highly resistant to fading, and provides excellent coverage, which is crucial for rubber products that require durability and longevity.

In the rubber industry, titanium dioxide serves multiple purposes. It enhances the mechanical properties of rubber products, improves their weather resistance, and provides a smooth, aesthetically pleasing finish. Moreover, the use of TiO₂ in rubber formulations can lead to improved UV stability, making it an ideal choice for outdoor applications such as tires, seals, and other rubber components exposed to the elements.

Benefits of Using Titanium Dioxide in Rubber

1. Improved Opacity and Whiteness One of the most significant advantages of incorporating titanium dioxide into rubber is its exceptional opacity. It allows manufacturers to produce high-quality white or colored rubber products with superior brightness and uniformity.

2. Enhanced Durability The inclusion of TiO₂ contributes to the overall durability of rubber products. It helps in strengthening the material, making it more resistant to wear and tear, which is particularly important in automotive and industrial applications.

3. UV Protection Titanium dioxide provides excellent UV protection, which is crucial for rubber products exposed to sunlight. This characteristic minimizes the degradation of rubber, thereby extending the lifespan of products such as tires and outdoor seals.

wholesale titanium dioxide for rubber

4. Cost-Effectiveness The use of wholesale titanium dioxide can lead to significant cost savings for manufacturers. By improving the quality and durability of rubber products, TiO₂ reduces the need for frequent replacements and repairs, ultimately lowering operational costs.

Sourcing Titanium Dioxide for Rubber Applications

When sourcing titanium dioxide for rubber manufacturing, it is essential to consider several factors to ensure quality and compatibility. Manufacturers should prioritize suppliers that provide high-purity TiO₂ with controlled particle sizes, as these attributes significantly impact the performance of the final product. Additionally, conducting thorough research and establishing relationships with reputable wholesale distributors can lead to better pricing and consistent supply.

It is also advisable to look for suppliers that offer comprehensive technical support and product data sheets. This information can aid in formulating rubber compounds that meet specific application requirements.

Emerging Trends in the Market

As industries evolve, so do their requirements for raw materials. The demand for eco-friendly and sustainable products has influenced the titanium dioxide market, leading to the development of bio-based alternatives. Furthermore, advancements in nanotechnology are enabling the creation of nano-sized titanium dioxide, which can enhance the performance of rubber products while minimizing environmental impact.

Additionally, the growth of electric vehicles (EVs) is driving demand for high-performance tires, which often require advanced formulations that include titanium dioxide. The tire industry is increasingly seeking materials that provide better grip, reduced rolling resistance, and enhanced fuel efficiency—areas where TiO₂ can play a pivotal role.

Conclusion

Wholesale titanium dioxide for rubber applications is a vital component that enhances product performance and durability. Its unique properties allow manufacturers to produce high-quality, long-lasting, and aesthetically pleasing rubber products. As the market continues to evolve with sustainability trends and technological advancements, the role of titanium dioxide will likely become even more critical in developing the next generation of rubber materials. By understanding the benefits and sourcing options, manufacturers can harness the potential of titanium dioxide to improve their product offerings and stay competitive in the growing rubber industry.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025