Nov . 13, 2024 19:51 Back to list

wholesale titanium dioxide filler

Wholesale Titanium Dioxide Filler Transforming Industries with Versatile Solutions

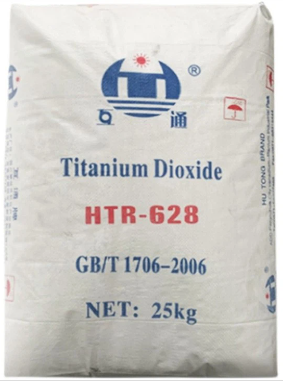

Titanium dioxide (TiO2) is a widely used inorganic compound renowned for its exceptional brightness and opacity. It has created a significant impact in various industries, particularly in paints, coatings, plastics, and paper, due to its outstanding properties. As a wholesale titanium dioxide filler, it serves as a critical ingredient, enhancing both the functionality and appearance of products. This article delves into the benefits, applications, and market dynamics surrounding wholesale titanium dioxide fillers.

The Versatility of Titanium Dioxide Fillers

One of the noteworthy attributes of titanium dioxide is its versatility as a filler. It is commonly available in two primary forms rutile and anatase. Rutile, the more stable form, exhibits superior whiteness, greater opacity, and improved weather resistance, making it the preferred choice for coatings and paints. In contrast, anatase is often considered for applications requiring lower obscuration and which benefit from its photocatalytic properties.

The excellent combination of strength, durability, and non-toxicity makes titanium dioxide fillers suitable for various sectors. They are particularly beneficial in applications where high-performance characteristics are essential, such as in automotive paints, industrial coatings, and even food-grade products.

Applications Across Industries

1. Paints and Coatings The most prominent application of titanium dioxide is in the paint and coatings industry. As a filler, it enhances the opacity and brightness of products, ensuring that less paint is needed to achieve the desired coverage. This results in cost savings and improved efficiency for manufacturers. Beyond aesthetics, TiO2 also contributes to the durability and weather resistance of paint, making it ideal for exterior applications.

2. Plastics In the plastics industry, titanium dioxide fillers improve the whiteness and brightness of products, including polyethylene, polypropylene, and PVC. They also enhance mechanical properties, such as tensile strength and impact resistance, contributing to the overall performance of plastic products.

wholesale titanium dioxide filler

3. Paper Manufacturing In the production of paper, titanium dioxide serves as a filler that increases brightness and opacity. This results in higher-quality printing products, ensuring that colors are vibrant and images are sharp. As a non-toxic material, it is also safe for use in food packaging applications.

4. Cosmetics and Personal Care Titanium dioxide is widely used in cosmetics as a pigment and thickening agent. It provides opacity to products such as foundation and sunscreen, while its UV-filtering properties protect the skin from harmful sun rays. Moreover, its non-reactive nature makes it an ideal choice for formulations used on sensitive skin.

5. Ceramics and Glass The use of titanium dioxide in ceramics and glass production is gaining momentum. It is vital for improving the brightness and enhancing the aesthetic appeal of finished products. Further, its unique properties provide beneficial effects in the functionality and strength of ceramic materials.

Market Dynamics and Trends

The wholesale titanium dioxide filler market is influenced by several factors, including growing demand in various industrial sectors, advancements in technology, and an increasing focus on sustainability. As industries strive to produce environmentally friendly products, the emphasis on non-toxic and sustainable raw materials like titanium dioxide continues to grow.

Additionally, the market is witnessing innovations in processing techniques, enhancing the quality and functionality of titanium dioxide fillers. With ongoing research, manufacturers are developing more efficient production methods, ensuring consistent quality while reducing waste and energy consumption.

Conclusion

Wholesale titanium dioxide fillers play a pivotal role in transforming multiple industries by providing high performance and versatile solutions. Their exceptional properties, wide-ranging applications, and strong market demand signify their importance in contemporary materials science. As industries continue to evolve, the role of titanium dioxide as a filler is set to expand, reinforcing its position as an indispensable ingredient that not only enhances product quality but also contributes to sustainable practices across the globe. By investing in innovative solutions involving titanium dioxide fillers, companies can drive growth, improve product offerings, and meet the ever-evolving needs of consumers.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025