Dec . 05, 2024 16:54 Back to list

Wholesale Titanium Dioxide for Masterbatch and Plastics Applications at Competitive Prices

The Significance of Wholesale Titanium Dioxide in Masterbatch and Plastic Production

Titanium dioxide (TiO2) has established itself as a fundamental component in various industries, especially in the manufacturing of masterbatches and plastics. As a versatile and widely used pigment, TiO2 is renowned for its exceptional whiteness, brightness, and opacity. The significance of wholesale titanium dioxide cannot be overstated, particularly when it comes to enhancing the quality of plastic products and masterbatches.

What is Titanium Dioxide?

Titanium dioxide is a naturally occurring mineral that is extracted from the earth and processed for various applications. It is mainly used as a white pigment due to its high refractive index and strong UV light absorption properties. In the context of masterbatches, which are concentrated mixtures of pigments and additives, TiO2 plays a crucial role in achieving the desired color and opacity in plastics.

Applications in Masterbatch Production

Masterbatches are essential in the production of plastic products as they allow manufacturers to incorporate colors and other functional properties into their base materials. Wholesale titanium dioxide is utilized in the creation of white masterbatches, which are used to produce a vibrant and opaque finish in several plastic applications. The advantages of using TiO2 in masterbatches include

1. Color Stability TiO2 provides long-lasting stability and brightness to colors, ensuring that plastic products maintain their visual appeal over time. 2. UV Resistance The inclusion of titanium dioxide in masterbatches enhances the UV resistance of plastic products, thereby extending their lifespan, especially for outdoor applications. 3. Heat Stability TiO2 is heat-stable, which makes it suitable for applications that involve high processing temperatures. This quality is critical in the extrusion and molding of plastics, where temperature control is paramount. 4. Versatility Titanium dioxide can be adapted for a wide range of plastic formulations, making it an essential additive for various applications, from packaging to automotive components.

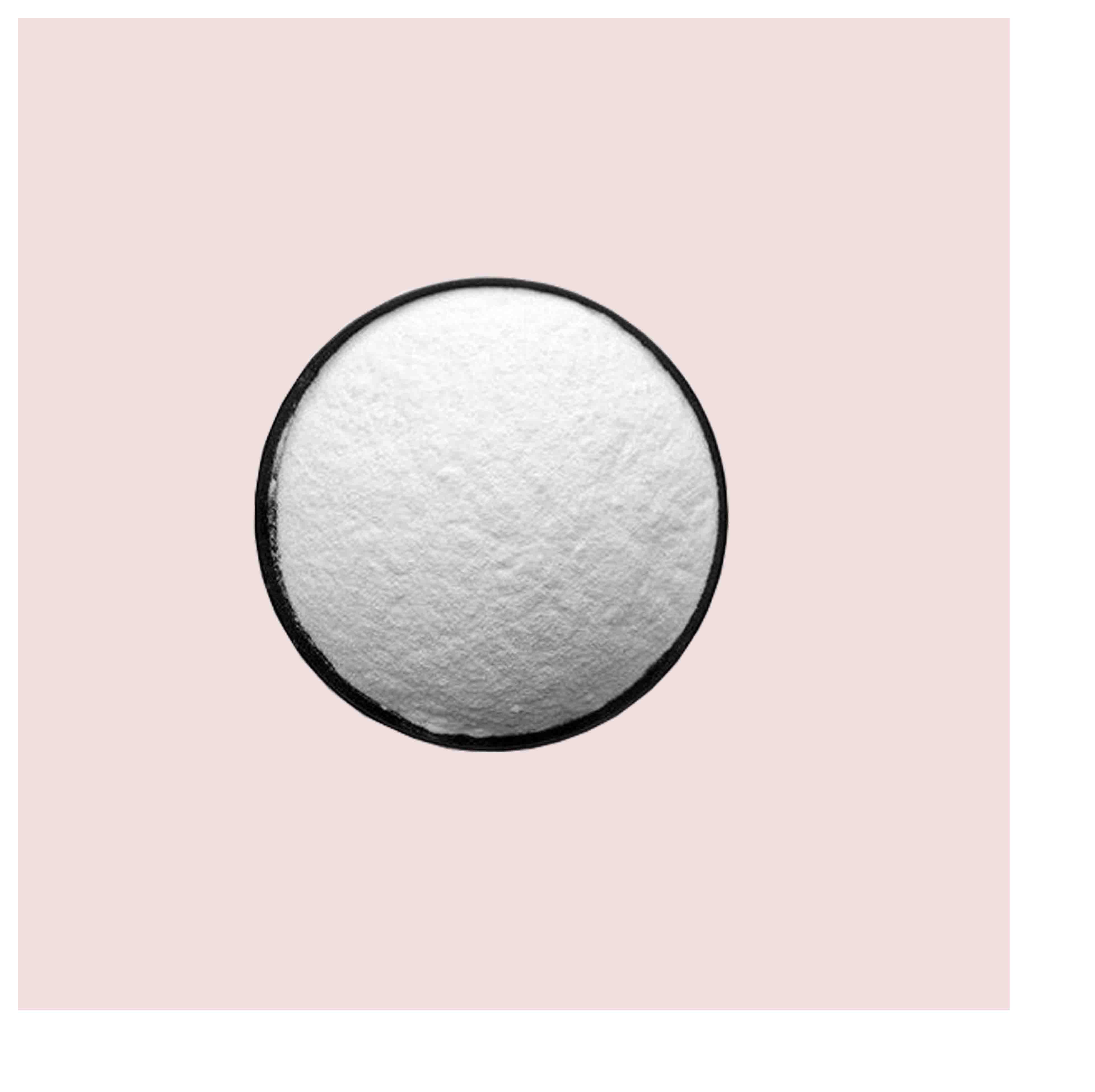

wholesale titanium dioxide especially for masterbatch and plastic use tio2

Benefits in Plastic Manufacturing

When utilized in plastic manufacturing, wholesale titanium dioxide serves multiple purposes beyond pigmentation. Its benefits include

- Enhanced Opacity The primary function of TiO2 in plastics is to improve opacity. This is particularly important for products that require concealment of substrates or those that must achieve a specific aesthetic. - Improved Processing Performance Titanium dioxide enhances the processing characteristics of plastics, facilitating easier handling and better flow during manufacturing. - Cost-Effectiveness Through its ability to provide high opacity and whiteness at lower loadings compared to other pigments, TiO2 can reduce overall production costs while maintaining product quality.

Market Demand and Supply Considerations

The demand for wholesale titanium dioxide continues to grow, driven by the expanding plastic industry and the increasing need for high-quality masterbatches. Manufacturers are continuously seeking reliable suppliers who can provide TiO2 with consistent quality while meeting the evolving standards and regulations of various markets. As environmental considerations become pivotal, sourcing TiO2 from sustainable practices is also gaining importance among manufacturers.

Conclusion

In conclusion, wholesale titanium dioxide is indispensable in the realm of masterbatch and plastic production. Its remarkable properties not only enhance the visual appeal and performance of plastic products but also contribute to cost-effective manufacturing processes. As industries continue to innovate and evolve, the role of titanium dioxide will likely expand, offering exciting prospects for advancements in material science and product development. Manufacturers keen on achieving superior quality and consistency in their offerings should consider the pivotal role that premium-grade titanium dioxide plays in their production processes.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025